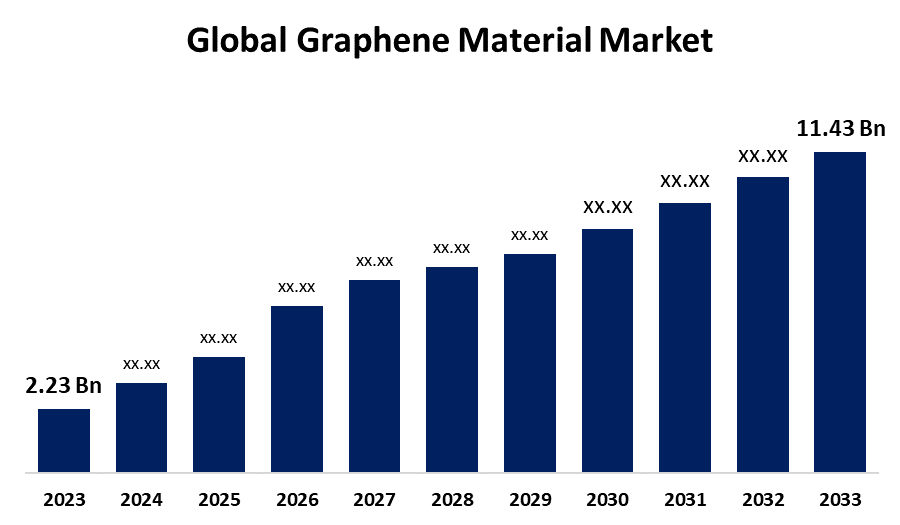

Graphene additives are fundamentally transforming the construction industry. According to analytical agencies, the graphene market has reached $195.7 million and is growing at a rate of 35.1% annually. Graphene in concrete increases compressive strength by 146%, improves waterproofing by 4 times, and enables the creation of «smart» building materials with self-diagnostic functions, working like the nervous system of a living organism. Nano-additives in concrete open a new era of energy-efficient and eco-friendly construction.

What are graphene additives in concrete and their unique properties

It should be noted that graphene additives are nanomaterials based on graphene — a two-dimensional structure of carbon atoms. Graphene nanoplatelets possess phenomenal strength — 200 times higher than steel with a weight of only 0.77 mg/m². Graphene oxide (a material with functional oxygen-containing groups) easily disperses in water thanks to functional groups on the surface, making it ideal for creating next-generation cement composites.

"Adding just 0.01-0.1% of graphene materials by weight to concrete mix increases Young's modulus by 80.5% and compressive strength by 146%. This is a significant breakthrough in materials science." — Dr. Monica Kračun, University of Exeter

The uniqueness of carbon nanomaterials lies in their multifunctionality. They simultaneously enhance the mechanical properties of concrete and give it electrically conductive characteristics. Could we have imagined ten years ago a material one atom thick capable of strengthening tons of concrete?

Application of graphene in various construction materials

Graphene concrete: breakthrough in strength and durability

Graphene concrete demonstrates impressive results compared to B25 grade concrete (strength class 25 MPa). Research shows an increase in flexural strength up to 79.5% (according to EN 12390-5 method). Concrete waterproofing increases by 4 times in capillary water absorption tests, which is critically important for infrastructure projects and high-rise construction.

Graphene concrete demonstrates impressive results compared to B25 grade concrete (strength class 25 MPa). Research shows an increase in flexural strength up to 79.5% (according to EN 12390-5 method). Concrete waterproofing increases by 4 times in capillary water absorption tests, which is critically important for infrastructure projects and high-rise construction.

Thus, the carbon nanomaterial addresses the main weakness of traditional concrete — its brittleness under tension. The history of revolutionary materials in architecture shows that the advent of reinforced concrete in the early 20th century enabled expressionists to create previously unseen curvilinear forms and sculptural buildings. Today, graphene additives continue this tradition of material innovation. Reinforcing concrete with graphene structures creates next-generation composite materials with enhanced crack resistance. Recent studies confirm that adding just 0.03% of reduced graphene oxide increases flexural strength by more than 40%. Not just an improvement — a true revolution.

At one of the sites last season, we observed how cement modification with graphene additives allowed laboratory calculations to show the possibility of reducing slab thickness by 25% while maintaining load-bearing capacity. Cement hydration (the process of chemical interaction with water) in the presence of carbon particles can proceed more uniformly, forming a dense structure of C-S-H gel (calcium hydrosilicate).

Comparative characteristics of ordinary and graphene concrete demonstrate significant advantages of nanomodified materials.

| Parameter | Ordinary concrete | Graphene concrete | Improvement |

|---|---|---|---|

| Compressive strength, MPa | 30-35 | 45-85 | +146% |

| Flexural strength, MPa | 3-5 | 5-9 | +79% |

| Waterproofing | Basic | 4 times higher | +400% |

| Cement consumption | 100% | 70% | -30% |

| Service life, years | 50-70 | Calculated estimates 100-150 | +100% |

This table clearly shows why innovative construction materials with graphene are becoming the standard of modern construction.

«Smart» construction materials with sensor functions

Self-sensing concrete is not science fiction. Graphene additives create a conductive network inside the material, allowing real-time monitoring of structural integrity using electrical monitoring methods. The piezoresistive effect provides changes in electrical resistance during deformation — a principle similar to how material responds to mechanical impacts, which is ideal for monitoring structures in road construction and bridge building.

"In our project in Dubai, graphene panels not only provided facade strength but also became part of the building monitoring system, tracking thermal deformations and loads." — Engineer Ahmed Al-Makt, Graphenano Smart Materials

In practice working with private clients, I often notice growing interest in «smart» technologies. Integration of IoT sensors with electrically conductive concrete opens incredible possibilities. The smart buildings market is rapidly growing, and graphene materials are becoming a key element of this transformation. Not just building — creating living structures. But this requires a new approach to design.

Environmental benefits of graphene additives and CO2 emission reduction

The environmental friendliness of graphene concrete impresses environmental engineers. Reducing cement use by 30% means significant reduction in CO2 emissions during production. Considering that the cement industry produces 8% of global carbon dioxide emissions, this is a promising solution for green construction and creating energy-efficient materials.

The environmental friendliness of graphene concrete impresses environmental engineers. Reducing cement use by 30% means significant reduction in CO2 emissions during production. Considering that the cement industry produces 8% of global carbon dioxide emissions, this is a promising solution for green construction and creating energy-efficient materials.

It is known that production of carbon nanomaterials is becoming economically viable. According to market estimates, if in 2020 the price of graphene nanoplatelets was $200-400 per kilogram, by 2025 it could drop to $100-200 for industrial volumes. Accessibility is growing like a snowball — the main thing is not to miss the moment.

In one of the recent building reconstruction projects, we managed to reduce the water-cement ratio by 15% thanks to the use of functionalized graphene. The result exceeded expectations: construction durability doubled while reducing carbon footprint by 35%.

Production and implementation technologies of graphene additives

Graphene dispersion in cement matrix requires special approaches. Ultrasonic dispersion ensures uniform distribution of graphene flakes without agglomeration. Surface functionalization improves adhesion with cement gel, overcoming the percolation threshold (critical concentration for forming a conductive network) at a concentration of 0.01-0.05% by mass.

"The key to success is proper dispersion preparation. We use surfactants to stabilize graphene suspension before mixing with cement. This prevents particle agglomeration and ensures maximum reinforcement effect." — Technologist Mark Johnson, First Graphene

Considering structural features, mechanical exfoliation of graphite remains the most practical method for industrial production of nanomaterials in construction. CVD graphene provides high quality but remains expensive for mass application. The intercalation process allows obtaining multilayer structures with controlled properties, which is particularly important for construction chemistry.

Real case: road signs project in the UK

"In May 2024, Breedon Group used 3 tons of PureGRAPH-CEM® graphene concrete to create road sign foundations on the highway. The result exceeded expectations: compressive strength increased by 30%, waterproofing by 4 times. Material savings amounted to 25%, which reduced carbon emissions and simplified logistics. The project became a catalyst for expanding graphene use in British infrastructure."

Limitations and practical challenges

Cost remains the main barrier. Graphene concrete is 5-10 times more expensive than ordinary concrete, limiting mass application in civil construction. Particle agglomeration with improper dispersion reduces efficiency by 60-80% — a critical problem for graphene material manufacturers.

"The main problem is ensuring stable quality of graphene material dispersion on an industrial scale. Even small deviations in technology can significantly reduce efficiency." — Dr. Sergey Kovalev, Research Institute of Construction Materials

As comparative analysis shows, multilayer carbon nanotubes provide 70% of graphene efficiency at half the cost. Nano-silica is 20 times cheaper but gives only 15-25% strength increase. The trade-off between price and quality is a key selection factor for industrial construction.

In practice, I often notice a shortage of qualified specialists in nanomaterial handling. Personnel retraining is needed. Should we be surprised by the slow technology implementation?

Practical recommendations for implementing graphene additives

Choosing graphene additives requires a systematic approach. Key criteria include technical parameters and compliance with international standards:

- Particle size (optimally 10-100 nm for nanoplatelets according to ISO 13320)

- Degree of surface functionalization

- Dispersion stability according to ASTM D7928

- Quality certification according to EN 197-1 (cement standard)

- Compatibility with CEM I-V cement (Portland cement types)

Verified suppliers include:

- First Graphene (Australia) — PureGRAPH® series

- Graphenano (Spain) — industrial volumes

- Applied Graphene Materials (UK)

- Haydale (Wales) — functionalized graphene

A checklist for selecting graphene additives will help avoid typical purchasing mistakes.

| Criterion | Optimal value | Verification method | Importance |

|---|---|---|---|

| Particle size | 10-100 nm | Laser diffraction | Critical |

| Carbon purity | >95% | Elemental analysis | High |

| Specific surface area | 500-750 m²/g | BET analysis | High |

| Dispersion stability | >24 hours | Sedimentation test | Critical |

| Surfactant compatibility | Confirmed | Trial mixing | Medium |

These criteria ensure maximum efficiency of graphene additives in real production conditions according to international standards ISO 21920 (nanoparticle measurement methods) and ASTM C39 (concrete strength testing).

Development prospects of graphene additives and future innovations

3D printing with graphene concrete is already a reality — the first printers can create structures with built-in sensors. Self-healing concrete with graphene catalysts is the next stage of construction industry evolution. What if tomorrow walls could repair themselves?

3D printing with graphene concrete is already a reality — the first printers can create structures with built-in sensors. Self-healing concrete with graphene catalysts is the next stage of construction industry evolution. What if tomorrow walls could repair themselves?

Thus, hybrid nanocomposites combining graphene with multilayer carbon nanotubes demonstrate synergistic effects in laboratory tests. Application prospects in creating supercapacitors open new horizons for smart concrete with sensors and autonomous power supply.

"The future belongs to programmable materials. Graphene sensors in structures will not only monitor condition but also actively adapt to changes in loads and climatic conditions." — Professor Andre Geim, Nobel Laureate

Innovations in the cement industry are accelerating thanks to production digitalization and machine learning. Real-time building health monitoring will become standard by 2030.