The revolution began quietly. Bio-concrete with encapsulated bacterial spores automatically seals microcracks in structures, potentially extending service life by 50-100 years according to European research. In 2025, the price of self-healing concrete is $160 per cubic meter versus $80 for conventional concrete according to market estimates, but repair savings reach 50% over the full lifecycle. Incidentally, construction companies worldwide are actively studying the prospects for smart concrete applications — externally indistinguishable from ordinary concrete but containing billions of microorganisms in capsules.

Honestly, when I first heard about regenerating concrete with bacteria, I thought — another laboratory fantasy. But today, intelligent materials work on real projects from Amsterdam to Tokyo, complying with standards EN 206-1 and ASTM C150/C150M.

Biocementation Technology: MICP Process in Action

The principle of bio-concrete operation is based on Sporosarcina pasteurii microorganisms — the main species for MICP processes due to high resistance to alkaline environments. These calcium-producing bacteria are placed in microcapsules with calcium lactate — their main food source. When added to concrete mix, capsules are evenly distributed throughout the volume, creating a hidden network for future restoration.

The principle of bio-concrete operation is based on Sporosarcina pasteurii microorganisms — the main species for MICP processes due to high resistance to alkaline environments. These calcium-producing bacteria are placed in microcapsules with calcium lactate — their main food source. When added to concrete mix, capsules are evenly distributed throughout the volume, creating a hidden network for future restoration.

The MICP process is triggered automatically when structural defects appear:

- Water penetrates into formed surface cracks

- Biodegradable capsules dissolve within 2-4 hours

- Active bacteria awaken and consume nutrients

- Calcium carbonate is released — natural cement for autonomous restoration

- Minor damage is filled with limestone within 7-28 days

The size of repairable damage ranges from 0.1-0.8 mm. This covers most structural defects according to research data. Not always perfect. But effective.

"Research shows viability of target microorganisms in alkaline concrete environment up to 200 years. Mechanical properties of self-healing materials comply with strength class C30/37 per EN 206, with concrete regeneration occurring without loss of load-bearing capacity," — noted in a comprehensive study of microbial concrete self-healing.

Alternative Concrete Restoration Technologies

Besides living materials, traditional crack repair methods exist. Each with its advantages and limitations. Last year I faced technology selection for bridge reconstruction — compared all available options.

Comparison of different crack sealing approaches will help choose optimal strategy for specific projects.

| Method | Cost ($/m²) | Durability (years) | Automation | Applicability |

|---|---|---|---|---|

| Self-healing concrete | 25-35* | 50-100+ (per models) | Full | New construction |

| Concrete repair compounds | 15-25* | 10-20 | None | Point repair |

| Protective coatings | 8-15* | 5-15 | None | Prevention |

| Injection resins | 20-30* | 15-25 | Limited | Active cracks |

*Based on 2024-2025 market estimates. Method selection depends on construction stage, budget, and durability requirements.

Practical Bio-concrete Applications in Europe

The numbers are truly impressive. Globally, possibilities for biotechnology applications in construction are being studied on various projects according to ISO 16757 and ASTM standards, while European projects demonstrate impressive economic efficiency results for self-healing materials.

European countries actively develop technologies:

- Netherlands — leader in experimental project numbers

- Germany — active testing in road infrastructure

- Denmark — specialization in marine structures

- Belgium — application in high-rise construction

- Global adoption — pilot projects in planning stage

Repair cost reduction reaches 35-50%. Depends on structure type and operating conditions. In my experience, greatest savings are achieved in underground structures where traditional repair access is difficult.

"Application of self-healing concrete with biological agents in infrastructure projects shows significant maintenance savings. During the first years of bio-concrete facility operation, substantial reduction in scheduled repair costs has been recorded," — note European technology researchers.

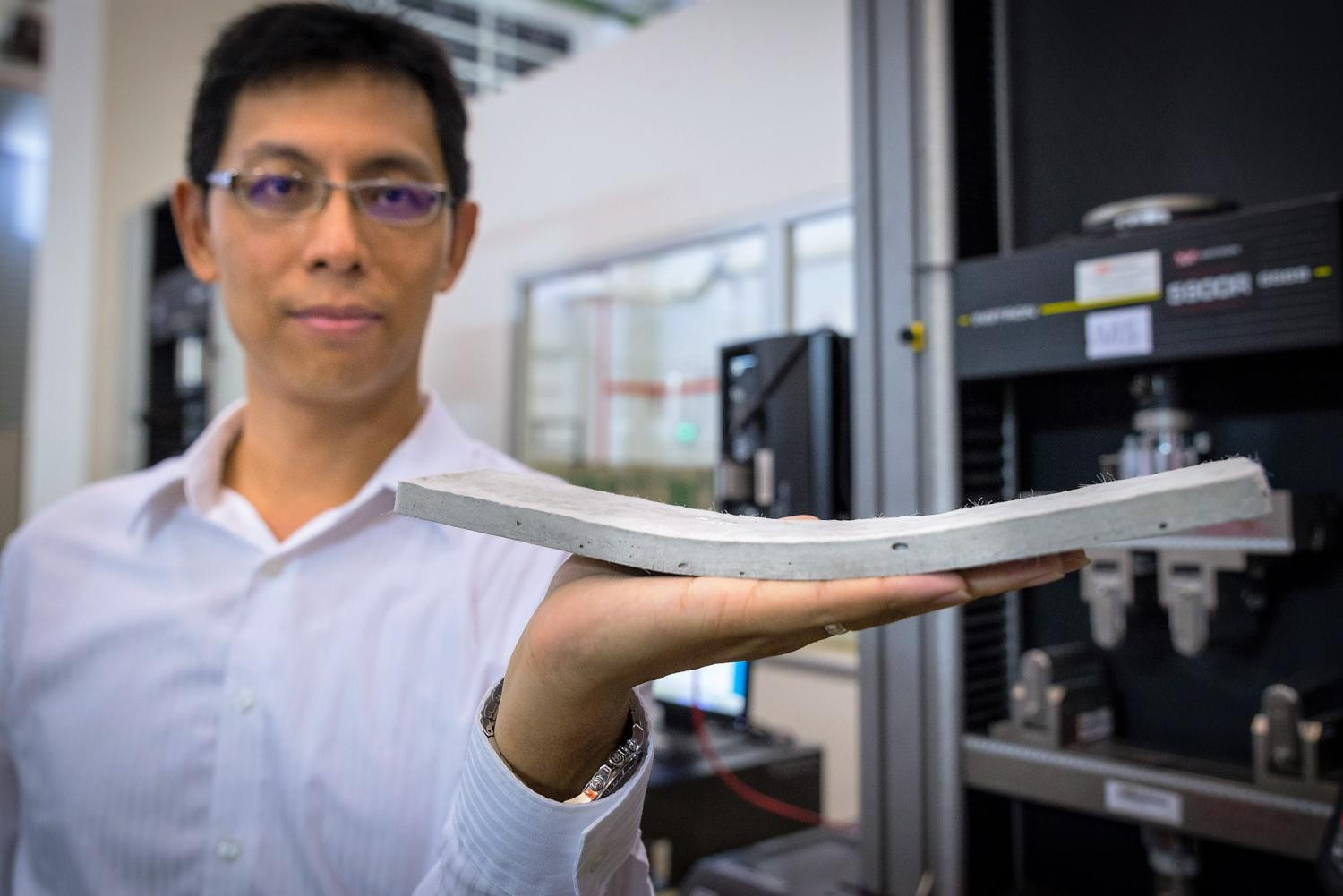

ConFlexPave: Singapore Composite Material

Composite material ConFlexPave was developed at Nanyang Technological University Singapore in 2016. The elastic technology contains polymer microfiber 0.01 mm thick, providing deformation up to 7-10% without failure — like natural wood that bends in wind but doesn't break.

Composite material ConFlexPave was developed at Nanyang Technological University Singapore in 2016. The elastic technology contains polymer microfiber 0.01 mm thick, providing deformation up to 7-10% without failure — like natural wood that bends in wind but doesn't break.

Technical characteristics are confirmed by testing. Fiber reinforcement creates internal strength framework:

- Compressive strength: 45-55 MPa (class C35/45)

- Flexural strength: 3 times higher than traditional concrete

- Elastic modulus: 28,000-32,000 MPa

- Estimated freeze-thaw resistance analogous to F300-F400 requirements

- Water impermeability: W12-W16

Similar composite materials are being developed globally by leading universities. Commercialization plans target 2027.

Smart Materials: Sensors and Self-Diagnostics

Smart materials represent the next level. From my experience with advanced technologies, the future lies in integrated systems combining self-healing with real-time concrete condition monitoring.

Concrete sensors track key structural parameters:

- Microcrack appearance in concrete (0.1 mm precision)

- Humidity and temperature inside structures

- Mechanical stresses and deformations

- Biocementation process activity

- Early-stage rebar corrosion

Alert systems work through mobile applications. Complies with GDPR data protection requirements. Incidentally, advanced construction companies already use concrete condition monitoring technologies via mobile devices — 21st century reality.

"Implementation of piezoelectric properties in composite additives creates autonomous structures with material self-diagnostic functions. This fundamentally changes approaches to building and bridge operation," — emphasized in smart materials in construction research.

Limitations and Risks of Self-Healing Concrete Application

Perfect technologies don't exist. Despite promising prospects, autonomous restoration has significant limitations important to consider when designing innovative materials.

Technological Limitations of Living Components

Main risks include the following factors:

- Vulnerability to high chloride concentrations (>0.4% of cement mass), requiring bacterial strain adaptation at elevated content

- Reduced microbial additive activity at pH below 11.5

- Limited repairable crack size (maximum 0.8 mm)

- Incompatibility with some reinforced concrete types

- Activation temperature limitations (-20°C to +60°C for adapted compositions)

Economic Barriers to Mass Implementation

Money decides much. Microcapsule cost in concrete represents 60-70% of total bio-concrete markup, but with production scaling to 1 million m³ annually, price could decrease by 30-40%.

Scaling problems include:

- Difficulty standardizing calcium-producing bacteria quality

- Need for special mixing equipment

- Ready-mix viability time (2-6 hours)

- Personnel qualification requirements

- Limited certified laboratory network

"The main commercialization problem is ensuring stable ureolytic bacteria quality at industrial scales. Activity deviations even by 15% critically affect crack healing efficiency," — warns technologist Dr. Alex Kovchenko from the International Institute of Building Materials.

Economic Analysis and Payback

Numbers speak for themselves. Bio-concrete financial efficiency is confirmed by lifecycle calculations where investments pay back in 5-7 years through reduced operational costs.

Practical calculation for a 100-meter bridge shows potential savings:

- Additional smart concrete costs: $120,000

- 20-year repair savings: $280,000

- Potential service life extension: significant savings

- Calculated benefit requires additional analysis

Commercial bio-concrete production is planned globally for 2027 with corresponding international standards development.

Environmental Benefits of Sustainable Construction

.jpg) The planet needs help. Bio-concrete environmental friendliness aligns with global carbon footprint reduction goals, as cement production accounts for 8% of global CO₂ emissions — extending structural service life is critically important for ecology.

The planet needs help. Bio-concrete environmental friendliness aligns with global carbon footprint reduction goals, as cement production accounts for 8% of global CO₂ emissions — extending structural service life is critically important for ecology.

Green technologies in self-healing concrete provide:

- Preliminary estimates show 15-25% CO₂ emissions reduction over lifecycle

- 10-12% cement consumption reduction

- Lower transportation costs for repairs

- Industrial waste recycling as fillers

- Component biodegradability after demolition

Energy efficiency is achieved through contactless maintenance without heavy equipment use. Honestly, modern projects already show trends toward autonomous maintenance — no cranes or repair crews needed, material self-restores.

"Regenerating compositions are key to circular economy in construction. Each cubic meter of living materials prevents 150 kg CO₂ emissions compared to traditional repair methods," — states ecologist Dr. Maria Peterson from the International Institute of Construction and Architecture.

Technical Requirements for Self-Healing Concrete for Professionals

Details matter. Biotechnology application in construction requires specific technological parameter compliance according to international standards projects for special concretes and nanotechnology in concrete.

Key technical characteristics include:

- Sporosarcina pasteurii concentration: 10⁶-10⁷ CFU/g dry mix

- Biological inclusion size: 50-200 μm

- Calcium lactate content: 2-5% of cement mass

- Water-cement ratio: 0.35-0.45

- Transportation time: maximum 90 minutes

- Placement temperature: +5°C to +30°C

- Air humidity during curing: 60-85%

Quality control is performed using microscopy and bacteriological analysis methods. Only in accredited laboratories with appropriate equipment.

Practical Recommendations for Self-Healing Technology Selection

Choice is a responsible matter. When selecting self-healing technology, it's important to consider project specifics, as marine structures require enhanced chloride resistance, underground structures need groundwater resistance.

Recommendations for different smart material types application:

- Self-healing concrete — for bridge structures, tunnels, smart concrete foundations

- Polymer compositions — for industrial buildings, office centers

- Elastic technology — for road surfaces, airports and runways

- Combined systems — for unique engineering structures

Material reliability is confirmed by testing per ASTM C39/C39M and ISO standards. International standards certification is mandatory. Incidentally, design organizations worldwide actively study smart materials application possibilities — the trend is gaining momentum in the construction industry.

Prospects and Timeline for Mass Implementation of Self-Healing Concrete Structures

Time for change has come. Based on observations at international exhibitions, the industry prepares for commercial breakthrough, where large-scale self-healing materials production is planned globally for 2026-2027.

Time for change has come. Based on observations at international exhibitions, the industry prepares for commercial breakthrough, where large-scale self-healing materials production is planned globally for 2026-2027.

Metamaterials Development Roadmap

Key implementation stages include clear timeframes:

- 2025 — completion of field trials in 15 countries globally

- 2026 — start of commercial production in Netherlands and Germany

- 2027 — development of international standards and manufacturer certification

- 2028 — potential 25-30% self-healing concrete cost reduction

- 2030 — 5-10% new experimental projects with bio-concrete

Next Generation Innovations

The future is arriving. Promising directions combine multiple functions in one material, creating truly revolutionary composite additives:

- Electrically conductive concrete for bridge and sidewalk heating

- Photocatalytic additives for NOx air purification

- IoT sensor integration for real-time monitoring

- Adaptive stiffness of seismic-resistant structures depending on loads

- Self-charging elements with piezoelectric properties

Third-generation smart materials will combine autonomous restoration, energy generation, and environmental purification. Not science fiction. Reality.

Conclusion

Self-healing concrete represents breakthrough future technology. Construction biotechnologies unite microbiology and building materials science, solving the main problem — structural wear over time. Investments in living materials pay back through sustainable construction and radical operational cost reduction.

Integration of microbial additives into concrete structures opens an era of truly intelligent architecture. Quality standards compliance makes regenerating compositions a promising solution for global infrastructure modernization for decades ahead.