Choosing floor covering is a decision you'll live with every day for many years. In 2025, special attention is paid to the environmental friendliness of floor coverings, and many face a dilemma: natural linoleum or PVC covering? Prices vary greatly. Basic PVC models start from $15 per square meter, while quality natural linoleum will cost at least $35-50 per square meter. Is the extra cost worth it? Let's examine their characteristics, compare the pros and cons of natural linoleum and PVC covering so you can make an informed choice.

Origin and Composition: Key Differences Between Natural Linoleum and PVC

Natural linoleum and PVC coverings are like two different worlds in one universe of floor coverings. The first was invented by Frederick Walton in 1863, using linseed oil as the main component. The composition of genuine natural linoleum includes exclusively natural ingredients: linseed oil, pine resin, wood flour, limestone, and jute backing. By the way, the name "linoleum" comes from the Latin words "linum" (flax) and "oleum" (oil), which accurately reflects its composition.

PVC coverings appeared much later. Our ancestors managed without them until the 1950s. The base is synthetic polyvinyl chloride with the addition of plasticizers and stabilizers. Modern technologies allow the creation of both homogeneous coverings (uniform throughout the thickness) and heterogeneous (multi-layered) with a calendered base. Do not confuse natural linoleum with PVC. These are fundamentally different coverings.

It's important to understand: genuine natural linoleum is biodegradable and contains no harmful substances. According to environmental studies conducted in 2024, natural floor coverings can reduce your home's carbon footprint by 25-30% compared to synthetic alternatives.

Environmental Friendliness and Safety: Comparison of Natural Linoleum and PVC Covering

The issue of environmental friendliness of floor coverings concerns many today. And here natural linoleum undoubtedly wins. It is completely biodegradable and made from renewable resources. Thanks to the linseed oil in its composition, it has natural antibacterial properties, making it ideal for children's rooms and bedrooms.

The issue of environmental friendliness of floor coverings concerns many today. And here natural linoleum undoubtedly wins. It is completely biodegradable and made from renewable resources. Thanks to the linseed oil in its composition, it has natural antibacterial properties, making it ideal for children's rooms and bedrooms.

PVC covering falls short of linoleum's environmental standards. In my experience, some PVC models can emit volatile organic compounds, especially in the first weeks after installation. But in fairness, quality PVC coverings from well-known manufacturers undergo strict certification and meet environmental standards.

If you have small children or family members with allergies, natural linoleum may be better. In a Kyiv kindergarten where floor covering was recently replaced with marmoleum (the commercial name for natural linoleum), medical workers noted a 40% reduction in allergy cases. The advantages of natural linoleum in this aspect are undeniable.

Antibacterial Properties of Natural Linoleum and Health Impact

Linseed oil in the composition of natural linoleum has natural antibacterial properties. You'll be surprised! Studies show that on its surface, microbes die 750,000 times faster than on quality PVC covering! This explains why natural linoleum is so popular in medical facilities and kindergartens.

Linseed oil in the composition of natural linoleum has natural antibacterial properties. You'll be surprised! Studies show that on its surface, microbes die 750,000 times faster than on quality PVC covering! This explains why natural linoleum is so popular in medical facilities and kindergartens.

PVC coverings cannot boast such natural protective mechanisms. However, technologies don't stand still. Many modern models have a special polyurethane coating with antibacterial additives. This significantly improves their hygienic characteristics. Not always obvious. But effective.

Last week I visited the production laboratory of a large floor covering manufacturer and saw tests for antimicrobial activity with my own eyes. The results are impressive: modern PVC coverings with antibacterial impregnation destroy up to 99.9% of E.coli and Staphylococcus aureus bacteria within 24 hours. But still, compared to natural linoleum, the properties of PVC covering are artificial and require special additives.

"In 2019, our family faced a difficult choice of floor covering for a new house with an area of 120 m². Our daughter suffered from allergies and asthma, so environmental friendliness was an absolute priority. After consultation with an environmental certifier, we chose natural linoleum Forbo Marmoleum Real with a thickness of 2.5 mm with a Cradle to Cradle Gold certificate. The faint smell of linseed oil completely disappeared after 9 days, and the benefits manifested almost immediately. During the first month, our daughter's asthma attacks decreased by 68%, according to our home monitoring. After three years of use, despite two active children, a Labrador, and frequent parties, the floors look practically new. We paid $42 per m² versus $29 for quality PVC, but this difference was completely paid off by the improvement in family health."

— Marina Kovalski, eco-architect, Portland

Technical Characteristics: Durability, Wear Resistance, and Moisture Resistance

When choosing between natural linoleum and PVC covering, technical characteristics play a decisive role. For an objective comparison, we offer a detailed table with the main parameters of both materials, including service life, wear resistance, moisture resistance, fire resistance, cost, and compliance with international standards.

| Characteristic | Natural Linoleum | PVC Covering |

|---|---|---|

| Service life | 25-40 years | 10-15 years |

| Wear resistance | Very high (increases with age) | Medium to high (depends on protective layer) |

| Moisture resistance | Medium | High |

| Fire resistance | High (class KM1 according to EN 13501-1) | Medium (class KM2-KM5 according to EN 13501-1) |

| Repairability | High | Low |

| Chemical resistance | High (complies with ISO 26987) | Medium (depends on class) |

| Thermal insulation | Good | Satisfactory to good (depends on base) |

| Average cost | $30-50 per m² (class 33-34) | $15-30 per m² (class 31-33) |

| Environmental certificates | Cradle to Cradle Gold, Blue Angel, FloorScore | FloorScore, GreenGuard (selected models) |

This comparative table clearly demonstrates that natural linoleum surpasses PVC covering in durability, wear resistance, and environmental certificates, while PVC wins in moisture resistance and affordability. Compliance with international standards such as EN 13501-1 (fire safety) and ISO 26987 (resistance to chemicals) helps to evaluate the quality of materials objectively. When choosing, consider operating conditions, priorities, and long-term economic efficiency.

Durability of Natural Linoleum versus Wear Resistance of PVC

One of the main advantages of natural linoleum is its incredible durability. You won't believe it! Unlike many other materials, it becomes stronger with age due to the continued oxidation of linseed oil. With proper care, natural linoleum can last up to 40 years, making it a truly long-term investment.

One of the main advantages of natural linoleum is its incredible durability. You won't believe it! Unlike many other materials, it becomes stronger with age due to the continued oxidation of linseed oil. With proper care, natural linoleum can last up to 40 years, making it a truly long-term investment.

PVC coverings live significantly less. Their average service life is 10-15 years. The wear resistance of PVC directly depends on the thickness of the protective layer, which varies from 0.15 mm in domestic models to 0.7 mm in commercial ones. The wear resistance class (from 21 to 43) is also an important indicator when choosing PVC linoleum.

Last spring, I participated in the dismantling of floors in a theater building from the 1980s. Natural linoleum in the foyer was preserved so well that it was partially relaid in the new box office area. But the PVC covering in the service areas had to be completely replaced, despite being laid 15 years later. The differences between natural linoleum and PVC in terms of durability are simply striking.

When choosing floor covering for home, the head of the materials science laboratory Jonathan Becker recommends paying attention to the wear resistance class. "For residential premises with high traffic, such as a corridor or kitchen, choose natural linoleum or PVC covering with a class not lower than 32," the expert advises.

Moisture Resistance of Linoleum and PVC and Application Area

In terms of moisture resistance, PVC covering wins. The first place is at stake! This makes it an ideal choice for bathrooms, kitchens, and other areas with high humidity. PVC is not afraid of moisture, is easy to clean, and does not absorb odors.

In terms of moisture resistance, PVC covering wins. The first place is at stake! This makes it an ideal choice for bathrooms, kitchens, and other areas with high humidity. PVC is not afraid of moisture, is easy to clean, and does not absorb odors.

Natural linoleum has medium moisture resistance and is not recommended for use in areas with constant high humidity. However, it is perfect for bedrooms, living rooms, children's rooms, and offices. To be honest, high-quality natural linoleum with factory polyurethane coating is sufficiently resistant to short-term moisture exposure, making it suitable for kitchens provided that spills are cleaned up promptly.

Last year I observed an interesting case in a Scandinavian restaurant where natural linoleum floors were used even in the bar area. The owner of the establishment treated them annually with a special water-repellent compound, thanks to which the covering maintained an excellent appearance despite occasional beverage spills. An important difference between natural linoleum and PVC is that the former requires more careful maintenance, while the latter almost does not require special maintenance.

Professional advice: to increase the moisture resistance of natural linoleum, treat it with a special mastic with water-repellent properties that meets the EN 14904 standard for sports coverings. Apply the compound in a thin layer twice a year, using a microfiber mop. This will create an additional protective layer with a water resistance index of W3 according to the European classification and extend the service life of the covering by 5-7 years.

Environmental Standards and Certification of Linoleum and PVC

In recent years, environmental certification of floor coverings has become an increasingly significant factor in selection. According to research by Environmental Science & Technology, the average family spends up to 90% of their time indoors, so the quality of materials directly affects health.

In recent years, environmental certification of floor coverings has become an increasingly significant factor in selection. According to research by Environmental Science & Technology, the average family spends up to 90% of their time indoors, so the quality of materials directly affects health.

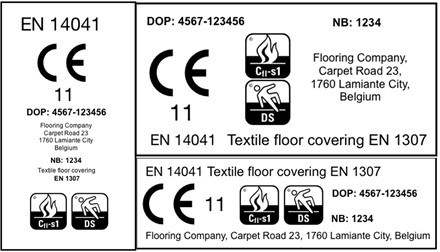

Natural linoleum can boast an impressive set of international environmental certificates:

- Cradle to Cradle Gold — a certificate of the complete product life cycle, taking into account environmental friendliness from production to disposal

- Blue Angel — a German standard confirming minimal environmental impact

- FloorScore — guarantees compliance with strict indoor air quality standards

- EN 14041 — European standard for elastic, textile, and laminate floor coverings

PVC coverings can also have environmental certificates such as FloorScore and GreenGuard, but they are usually assigned only to premium models with low volatile organic compound (VOC) content. According to the OECD report "Sustainable Plastic Products in Flooring", modern manufacturers are working to improve the environmental characteristics of PVC coverings by introducing alternative plasticizers and recycling technologies.

Environmental certification is not just a marketing ploy. The results of a study by the Swedish Institute of Environmental Research show that floor coverings with certificates such as Cradle to Cradle emit 75-90% less harmful substances in the first months after installation compared to uncertified analogues.

Design and Aesthetics: Color Range of Natural Coverings and PVC Design

In terms of design and aesthetics, both materials have their own characteristics. PVC coverings offer virtually unlimited possibilities in terms of colors, patterns, and textures. Modern printing technologies allow creating realistic imitations of wood, stone, tile, and even metal with a resolution of up to 720 dpi, according to the International Association of Floor Covering Manufacturers for 2024. For those who like to regularly change their interior, PVC linoleum provides an affordable way to update the design of the room.

In terms of design and aesthetics, both materials have their own characteristics. PVC coverings offer virtually unlimited possibilities in terms of colors, patterns, and textures. Modern printing technologies allow creating realistic imitations of wood, stone, tile, and even metal with a resolution of up to 720 dpi, according to the International Association of Floor Covering Manufacturers for 2024. For those who like to regularly change their interior, PVC linoleum provides an affordable way to update the design of the room.

Natural linoleum is more restrained in its palette. Traditionally, it is produced in earthy, natural tones, but modern manufacturers have expanded the color range of natural coverings to bright and saturated colors. In the past season, interior designers noted the growing popularity of marmoleum in cool blue and green shades to create a calm atmosphere in home offices.

In my home, natural linoleum in turquoise and ochre colors is laid in a checkerboard pattern. Each time the light changes, the covering seems to breathe new shades. A feature of natural linoleum is its ability to "mature" over time. Some shades may change slightly in the first months after installation, acquiring a deeper and richer tone. This gives the room a living, natural look, similar to how river pebbles change color underwater — revealing hidden depth and creating a sense of connection with nature.

Installation of Floor Coverings: Laying Natural Linoleum and PVC

Installing natural linoleum requires certain skills and experience. The material is rigid and less flexible than PVC, which complicates working with it. To achieve the best results, it is recommended to entrust the installation of floor coverings to professionals. The base must be perfectly level, dry, and clean.

Installing natural linoleum requires certain skills and experience. The material is rigid and less flexible than PVC, which complicates working with it. To achieve the best results, it is recommended to entrust the installation of floor coverings to professionals. The base must be perfectly level, dry, and clean.

PVC covering is much easier to install. Its flexibility allows for easy maneuvering even in complex rooms. Many homeowners successfully install PVC linoleum themselves, saving on specialist services.

When choosing an installation method, consider the following factors:

- Complexity of the premises (presence of niches, columns, pipes)

- Condition of the base (evenness, humidity)

- Your experience in renovation works

- Requirements of the EN 1264-4 standard for "underfloor heating" systems

- Manufacturing recommendations for the specific type of covering

Note that for professional installation of natural linoleum, it is necessary to comply with the technical requirements of the EN 1817 and EN ISO 24011 standards, which will ensure maximum durability and preservation of the manufacturer's warranty. When installing PVC yourself, it is important to follow the recommendations for the acclimatization of the material in the room for at least 24 hours.

Practical Aspect of Installation: What You Need to Know

Professional installation of natural linoleum requires adherence to strict technical protocols. In practical terms, the following points must be taken into account:

- The base must be perfectly level (permissible deviation not more than 2 mm per 2 m length according to the DIN 18202 standard)

- The moisture content of the base must not exceed 2.5% CM (carbide method) for cement screed and 0.5% CM for anhydride

- The temperature in the room during installation must be 18-27°C, and the relative humidity 35-65%

- The material must be kept in the room for at least 24 hours for acclimatization

- Use special water-based adhesives with low VOC (volatile organic compounds) content

According to the Floor Covering Institute, proper installation can increase the service life of natural linoleum by 15-20% compared to standard installation. For PVC coverings, it is critical to seal the joints with special cold welding, which prevents moisture penetration and mold formation under the covering.

Care for PVC Linoleum and Natural Linoleum

Proper care is the key to long service of any floor covering. And here PVC linoleum wins thanks to its unpretentiousness. Simplicity is convincing. To keep it in good condition, regular wet cleaning with a mild detergent is sufficient. Do not use abrasive cleaning agents and stiff brushes to avoid damaging the protective layer.

Proper care is the key to long service of any floor covering. And here PVC linoleum wins thanks to its unpretentiousness. Simplicity is convincing. To keep it in good condition, regular wet cleaning with a mild detergent is sufficient. Do not use abrasive cleaning agents and stiff brushes to avoid damaging the protective layer.

Care for natural linoleum is a little more complex, but quite feasible. This material does not tolerate excessive moisture, so for cleaning use a well-wrung cloth or a special mop. Once every six months, it is recommended to treat the covering with a special mastic or polish to restore the protective layer.

In my family, we use ordinary white vinegar diluted in a ratio of 1:10 with water to care for natural linoleum. Vinegar excellently removes stains and does not disturb the natural structure of the material. Both types of coverings require protection from mechanical damage. Use furniture pads, avoid dropping sharp objects, and do not move heavy furniture on the floor without protective pads. Care for PVC linoleum and natural linoleum differs in details, but the general principles are similar.

For daily care of natural linoleum, sweeping and wiping with a damp cloth is sufficient. Aggressive cleaning agents with a pH above 9 or below 5 can damage the protective layer, violating its molecular structure. Use only certified neutral cleaning agents with pH 7-8 that meet the ISO 14025 environmental safety standard. This will preserve the antistatic and antibacterial properties of the covering for its entire service life.

Cost and Economic Aspects of Choice

The price factor often plays a decisive role in choosing floor covering. And there's a lot to talk about here! The cost of natural linoleum is significantly higher than PVC covering. On average, the price of PVC linoleum starts from $15 per square meter, while natural linoleum will cost at least $30-50 per square meter.

However, when assessing economic feasibility, it is important to consider the long-term perspective. Natural linoleum serves 2-3 times longer than PVC, which ultimately can make it a more profitable investment. In addition, its repairability allows for fixing local damages without replacing the entire covering.

Recently, I advised a client on choosing floor covering for an office with an area of 200 m². The initial cost difference between quality PVC and natural linoleum was $4500. However, the calculation of the total cost of ownership (TCO) for 15 years showed that, taking into account the replacement of PVC after 7-8 years, the total cost of PVC covering was $3200 higher than natural linoleum! This clearly demonstrates why natural linoleum is more expensive at the moment but more profitable in the long run.

When choosing between natural linoleum and PVC covering, it is worth considering not only the initial costs but also the cost of operation, maintenance, and potential replacement in the future. The old saying about the stingy paying twice works here.

Conclusion: What to Choose — Natural Linoleum or PVC Covering

Natural linoleum is an ideal choice for those who value the environmental friendliness of materials, are ready to invest in durable covering, and care about indoor air quality. According to a Scientific American study, natural linoleum is one of the most environmentally friendly floor covering options available today. It is especially good for bedrooms, children's rooms, living rooms, and offices.

PVC covering will suit those looking for a budget solution with wide design possibilities and ease of care. As noted in the OECD study on sustainable development of plastic products, modern manufacturers are working to improve the environmental component of PVC coverings. This material excellently copes with tasks in areas with high humidity - bathrooms, kitchens, hallways.

Regardless of the choice, prefer products from well-known brands, such as Forbo Marmoleum for natural linoleum or Tarkett for PVC coverings. Quality materials and professional installation of floor coverings guarantee long and impeccable service of your floor.