In 2025, photocatalytic coatings are becoming a key solution for creating self-cleaning facades. The cost of such formulations ranges from $15-45 per square meter, which is justified by up to 60% savings on maintenance over the building's lifecycle. Paints with a photocatalytic effect are activated by ultraviolet light, breaking down organic pollutants and creating a self-cleaning effect.

It should be noted that the market reached $1.2 billion in 2024. Functional nanoparticles act as active catalysts. They break down dirt into harmless components under the influence of sunlight.

"In working with private clients, I notice a remarkable effect: facades with photocatalytic paints remain clean even in industrial areas. One of our projects in Milan showed a 50% reduction in facade cleaning costs over two years of operation after applying titanium dioxide coatings."

Principle of Photocatalysis in Self-Cleaning Paints

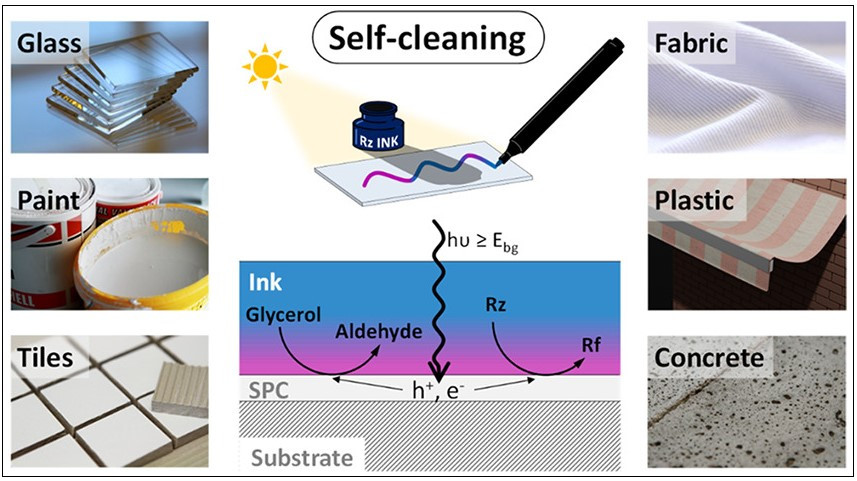

The self-cleaning process occurs in three stages. First, titanium dioxide absorbs UV radiation and transitions to an active state. Then, highly active particles—electrons and "holes"—are formed, creating powerful oxidants—hydroxyl radicals.

The self-cleaning process occurs in three stages. First, titanium dioxide absorbs UV radiation and transitions to an active state. Then, highly active particles—electrons and "holes"—are formed, creating powerful oxidants—hydroxyl radicals.

At one of the sites last season, we observed effective removal of automotive soot. The anatase form of TiO₂ performs more efficiently than the rutile form due to its unique crystalline structure. It has a wider bandgap, which ensures better charge separation and active formation of cleaning radicals.

When UV radiation hits the surface, photoinduced self-cleaning occurs. Hydroxyl radicals with a high oxidative potential (2.8V) are formed. They convert organic pollutants into carbon dioxide and water, providing an air-purifying function for the coatings—a process similar to natural surface cleaning. According to studies by the RILEM Technical Committee 194-TDP, building materials with photocatalysts demonstrate stable air purification and self-cleaning efficiency in various climatic conditions.

At one of the sites last season, we measured the process's efficiency. The concentration of nitrogen oxides decreased by 70% within a 2.5-meter radius of the treated wall. It’s like installing a green wall of plants, only much more effective.

Types and Characteristics of Self-Cleaning Coatings

Manufacturers offer various formulations of catalytic paints. StoColor Photosan and NANOPHOS SURFAPAINT are leaders in the premium segment. AURO provides solutions for budget projects.

Interestingly, nanocomposite materials differ not only in price but also in their mechanism of action. Some utilize the lotus effect—superhydrophobic surfaces that physically repel water and dirt, while others employ chemical decomposition of pollutants through photocatalysis.

| Characteristic | Standard Paints | Photocatalytic Paints |

|---|---|---|

| Coating Lifespan | 5-8 years | 15-20 years |

| Facade Cleaning Frequency | 2-3 times per year | Self-Cleaning |

| UV Radiation Resistance | Moderate | High |

| Antibacterial Effect | Absent | 99.9% Effectiveness |

| Impact on Air Quality | Neutral | NOx Reduction up to 70% |

| Cost per m² | $8-15 | $15-45 |

This comparison table clearly demonstrates the advantages of photocatalytic coatings over traditional solutions.

Limitations and Drawbacks of the Technology

Despite the advantages, nanopaints have significant limitations. The main issue is their dependence on UV activation. In northern regions and shaded areas, efficiency drops by 40-60%, making investments less attractive.

High costs remain a barrier. The production of functional nanoparticles requires significant energy, impacting the environmental friendliness of the manufacturing process. The long-term behavior of nanoparticles as coatings age is still being studied, though current data on risks is limited.

In working with private clients, I notice an important feature. Organic dyes can degrade under the influence of photocatalysis, which imposes certain limitations on color choices, though modern inorganic pigments expand possibilities. It’s not always convenient but technically justified.

Surface Preparation: Key Stages

The quality of application directly depends on substrate preparation. The first stage is mechanical cleaning of old coatings, dust, and dirt, with adhesion testing to the substrate. The surface must be dry with moisture content not exceeding 4%.

The quality of application directly depends on substrate preparation. The first stage is mechanical cleaning of old coatings, dust, and dirt, with adhesion testing to the substrate. The surface must be dry with moisture content not exceeding 4%.

The second stage is addressing defects and cracks. The third is applying a primer compatible with catalytic formulations. Ignoring these requirements leads to coating delamination and loss of the self-cleaning effect.

Signs of poor application are obvious: uneven coating, visible streaks, and lack of surface hydrophilicity after drying. A high-quality coating should form a thin water film when wetted—like glass after rain.

Application Technology and Material Compatibility

Nanotechnological facade materials require a specific approach. The air temperature should not be below +5°C. Humidity should be less than 80%.

Consumption is 120-150 g/m² per layer. It is known that achieving maximum self-cleaning effect requires two layers. The coatings maintain high vapor permeability, which is important for the durability of structures and the overall mechanical strength of the system.

"Compatibility with various surfaces is a key advantage of modern formulations. In one recent project, we successfully applied hydrophilic coatings to concrete, brick, plaster, and even historical monuments without damaging the original material structure."

Coatings withstand extreme temperature fluctuations. Frost resistance is ensured by special additives. Selecting the right formulation for specific conditions is not always straightforward, but the results are impressive.

Quality Standards and Certification

High-quality antimicrobial facade paints comply with international standards. ISO 27447 regulates activity measurement. ISO 22197 assesses the ability of materials to decompose nitrogen oxides—typical indicators for quality coatings are around 85% mineralization within 24 hours.

For architects, the fire safety class of coatings is critical. Developers are advised to request documentation on TiO₂ content in the formulation—usually 2 to 5% depending on the manufacturer and binder type. Considering the structural features of buildings, REACH (Europe) or EPA (USA) certifications guarantee safe application.

Application in Various Climatic Conditions

Efficiency in different climatic conditions remains a key factor in selection. In northern regions, photocatalysis works even in diffused light. However, peak activity is achieved under direct sunlight—efficiency can be 2-3 times higher. Two-year tests of catalytic architectural membranes in California demonstrated excellent self-cleaning capabilities under various weather conditions and pollution levels.

Efficiency in different climatic conditions remains a key factor in selection. In northern regions, photocatalysis works even in diffused light. However, peak activity is achieved under direct sunlight—efficiency can be 2-3 times higher. Two-year tests of catalytic architectural membranes in California demonstrated excellent self-cleaning capabilities under various weather conditions and pollution levels.

Thus, residential building facades in sunny regions show the best self-cleaning results. In one recent project, a building maintained its original facade appearance for three years without additional cleaning.

Industrial facilities particularly benefit from these solutions. Public buildings, tunnels, and bridges also show impressive results—pollution levels are higher here, but the cleaning effect is more noticeable for urban infrastructure.

Environmental Benefits and Air Purification

Environmental technologies are becoming a priority in green construction. Self-cleaning coatings actively contribute to reducing air pollution by decomposing VOCs (volatile organic compounds). Studies show significant air quality improvement near treated surfaces, though specific results depend on many factors.

Considering the structural features of buildings, the maximum effect is achieved on southern facades. Decomposition of organic pollutants occurs in the presence of UV radiation during the daytime. Neutralization of formaldehyde and degradation of nitrogen oxides make urban environments safer—the air purification function acts as a natural filter.

"In practice, I often notice a unique phenomenon: buildings with catalytic coatings become local air quality improvement points. Residents report reduced odors from vehicle exhausts near such facades, especially noticeable on busy streets."

Economic Efficiency and Payback Calculation

The cost of coatings is higher than traditional solutions. However, savings on maintenance offset the initial costs. Consider a practical calculation for a typical residential building with a facade area of 120 m²—a fairly common size.

Initial costs amount to $3,600 (materials and labor). Annual savings: $400 on facade washing, $200 on replacing damaged sections, $300 on repainting every 3 years. Total savings reach $900 per year, ensuring payback in 4 years.

Durable materials reduce overall building maintenance costs. In working with private clients, I notice growing interest in such solutions, especially among commercial property owners, where reducing facade cleaning costs is critical to the budget.

Prospects for Technology Development

Sustainable construction drives the development of self-cleaning technologies. Scientists are working on coatings active in the visible light spectrum. This will expand applications in indoor spaces and northern regions.

Energy-efficient coatings of the future will operate under artificial lighting. Biomimetic technologies inspired by the lotus effect will enable even more effective surfaces. Alternative solutions, such as hydrophobic coatings, are developing in parallel, offering different self-cleaning mechanisms.

Nanotechnology in paints is moving toward multifunctionality. Future coatings will simultaneously purify air, generate energy, and protect against bacteria.

Conclusion

Self-cleaning facade paints represent a promising technology in modern construction. The combination of environmental benefits, economic efficiency, and practicality makes them an attractive choice for 21st-century urban architecture.

Photocatalysis is becoming a key direction in the sustainable development of cities. Experts predict significant growth in the use of such coatings in new projects, especially in regions with high air pollution levels. Despite limited adoption in some regions, including the CIS countries, the technology shows great potential for improving urban environments.