Many people think that hardboard is the same as fiberboard or that there is no difference between these materials. This is not entirely true. The difference between fiberboard and hardboard is significant and affects the choice of material for specific tasks. According to 2025 research data, the price of hardboard exceeds the cost of regular fiberboard by 15-30% due to improved characteristics.

Expert advice: When choosing between fiberboard and hardboard, consider the operating conditions. For humid rooms, use hardboard with moisture-resistant treatment.

What is fiberboard and what is hardboard

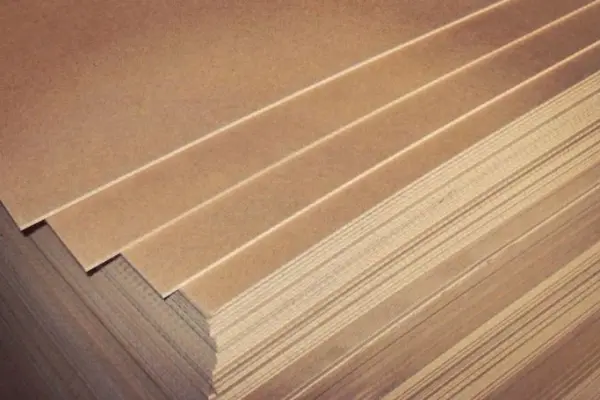

Fiberboard is a sheet material made from wood fibers. It is produced by hot pressing at a temperature of 210-230°C. By the way, many people confuse composite panels with hardboard, although the latter is a variety of the former.

Fiberboard is a sheet material made from wood fibers. It is produced by hot pressing at a temperature of 210-230°C. By the way, many people confuse composite panels with hardboard, although the latter is a variety of the former.

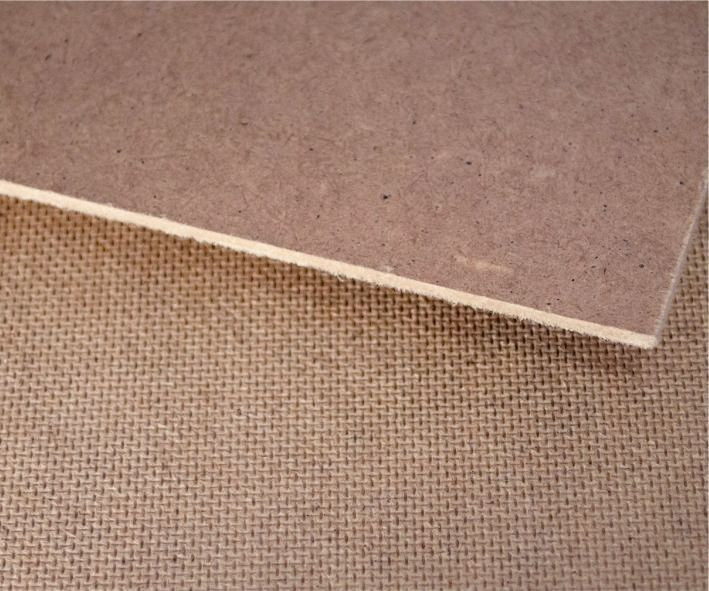

What is hardboard in simple terms? It is a hard high-density fiberboard with decorative treatment of one side. The specific gravity ranges from 800 to 1100 kg/m³. It is distinguished by a smooth front surface and may have a laminated coating — like an elegant suit for an ordinary board.

Types of fiberboard differ dramatically. Soft panels are more like insulation. Hard sheet materials resemble thin plywood. And hardboard or fiberboard - which is better? It depends on the specific task and project budget.

Main differences between fiberboard and hardboard

A comparative table will help understand the key differences between materials and choose the optimal option.

| Characteristic | Regular fiberboard | Hardboard |

|---|---|---|

| Density, kg/m³ | 200-800 | 800-1100 |

| Thickness, mm | 3-25 | 2.5-6 |

| Surface | Rough on both sides | One side smooth |

| Moisture resistance | Low | Enhanced |

| Price per sheet, $ | 8-15 | 12-25 |

The data shows that the choice between materials depends on the specific project requirements.

Composition and chemical differences of materials

Binding agents determine the main differences between fibrous sheets and refined boards. But why is composition so important? Regular wet-process fiberboard uses natural lignin — a wood component that activates when heated to 180°C.

Decorative panels contain synthetic resins. Urea-formaldehyde makes up 4-6%, phenol-formaldehyde — 2-4%. Paraffin and rosin additives in production increase hardboard moisture resistance by 40-60%. According to international standards EN 13986 and CARB Phase 2, formaldehyde emission should not exceed 0.1 ppm for emission class E1.

Expert opinion: Modern manufacturers have reduced formaldehyde content in decorative boards by 70% over the past 15 years thanks to improved binding compositions.

Production technology and grades of sheet materials

Fiberboard production is carried out in two ways. The wet method uses water to transport fibers through a defibrator. The dry method uses synthetic resins as binding agents, passing coniferous and deciduous chips through a refiner.

Fiberboard production is carried out in two ways. The wet method uses water to transport fibers through a defibrator. The dry method uses synthetic resins as binding agents, passing coniferous and deciduous chips through a refiner.

Honestly speaking, the wet method is more environmentally friendly. It does not require formaldehyde resins. But the dry method produces a stronger composite material with better water resistance of wood boards, especially when using fine dispersed mass.

Practical advice: Masonite (fibrous boards with mesh back side) is excellent for furniture backs, and veneer-faced fiberboard — for facades.

Fiberboard grades differ by material compactness:

- M (soft) — 150-400 kg/m³, used for thermal insulation

- NT (semi-hard) — 400-800 kg/m³, used in furniture production

- T (hard) — over 800 kg/m³, suitable for finishing

- ST (super-hard) — over 950 kg/m³, used for flooring

Last year I encountered an interesting fact. Hardboard production technology includes additional lamination of boards under pressure of 25-30 MPa. The result is impressive.

Material comparison: hardboard or fiberboard which is better

Last year I faced the choice of material for office renovation. Regular fibrous sheets were perfect for leveling walls under wallpaper. But for drawer bottoms, I had to choose decorative panels — they withstand heavy loads.

What is better for furniture: fiberboard or hardboard? The answer is ambiguous. It depends on the specific application and bending strength requirements.

"I used refined boards with a thickness of 4 mm to make 700 information stands in public places. The material showed excellent resistance to weather conditions and was easy to process. Over three years of operation, there was virtually no damage. The project exceeded expectations for durability and appearance." — Jacob Richards, artist-designer

Decorative fiberboard with lamination exceeds regular fiberboard in moisture resistance by 3-4 times. Veneer-faced fiberboard has improved aesthetic qualities. But it costs more. The choice is not always obvious.

Fiberboard vs MDF: brief comparison

MDF is denser than composite panels (600-800 kg/m³ vs 200-400 kg/m³). Holds fasteners better. But fiberboard is 20-40% cheaper and more environmentally friendly with wet production method.

Application in furniture production

Cabinet backs are made from thin fiberboard with a thickness of 3.2 mm. Drawer bottoms require stronger sheet material — refined panels or hard composite sheets.

Cabinet backs are made from thin fiberboard with a thickness of 3.2 mm. Drawer bottoms require stronger sheet material — refined panels or hard composite sheets.

Modern furniture manufacturers increasingly choose refined fiberboard. It combines the strength of decorative panels with aesthetic properties. The coating imitates wood, stone or metal, and hardboard facing looks quite convincing.

How to distinguish hardboard from regular fiberboard in production? Simple. The refined material has one side smooth as a mirror. Regular has both rough.

Specialist recommendation: For children's furniture, choose materials of emission class E1 with minimal formaldehyde content.

Construction work and finishing

Rough wall finishing allows the use of unrefined fiberboard. Laminate substrate requires composite material with increased compactness. Soundproofing is more effective with soft grades of fibrous sheets.

In my experience, decorative panels are excellent for interior finishing of dry rooms. Smooth and mesh surfaces do not require additional treatment before painting. Wood boards are like a universal tool for a builder.

Where is hardboard used most often? In "economy" class room finishing. A good alternative to expensive materials. Practical and functional.

Practical tips for working with sheet materials

Cutting fibrous sheets and decorative panels requires different approaches. Soft fiberboard is cut with a utility knife. Hard composite materials — with a jigsaw with fine teeth. Feed speed — 2-3 m/min to prevent chipping.

How do they make hardboard more resistant to damage? Proper storage. Placement should be horizontal in a dry room. Air humidity not higher than 65%. Refined boards are less sensitive to moisture but require protection of edges from wetting.

Master's advice: Before installation, keep sheets in the room for 24-48 hours for acclimatization. This will prevent deformation after installation.

Environmental friendliness and safety

Binding agents in fiberboard affect environmental friendliness. Urea resins emit less formaldehyde than phenolic ones. Paraffin and rosin are natural hydrophobizers, safe for health. In Russia, SanPiN 1.2.3685-21 is in effect, limiting formaldehyde content in air to 0.01 mg/m³.

Lignin is a natural binder in soft fiberboard. Contains no synthetic additives. Makes the material completely environmentally friendly. According to European research, the market for environmentally friendly wood boards is growing by 8% annually. In Ukraine, DSN 3.3.6.042-99 is used to control air quality in premises.

Sizes and standards

GOST 4598-86 regulates fiberboard sheet sizes in Russia and CIS countries. Standard format: 2745×1220 mm. Thickness varies from 2.5 to 25 mm depending on the grade. In Ukraine, DSTU B V.2.7-161:2008 is in effect, which supplements GOST requirements for environmental safety.

European standard EN 622 establishes classification of HDF (high density) and MDF (medium density). In Russia, SP 64.13330.2017 is additionally used for construction use of wood boards.

Important to know: When calculating the amount of material, consider that hardboard is supplied in sheets of smaller thickness but higher density. According to TU U 20.1-14307883-032:2009, the moisture content of finished boards should not exceed 7%.

What to choose: final recommendations

A practical table will help determine the optimal material for specific tasks based on operating conditions.

| Task | Recommended material | Justification |

|---|---|---|

| Furniture backs | Fiberboard 3.2 mm | Economical, sufficient strength |

| Drawer bottoms | Hardboard 4-6 mm | Withstands load, moisture resistance |

| Wall leveling | Unrefined fiberboard | Low price, for finish coating |

| Soundproofing | Soft fiberboard M-12 | Porous structure absorbs sound |

| Laminate substrate | Hard fiberboard T | Even surface, stability |

| Furniture facades | Laminated hardboard | Decorative, wear resistance |

Material selection should be based on a balance of price, functionality and durability for each specific application.

The choice between fibrous sheets and decorative panels depends on specific tasks and operating conditions. Refined boards exceed regular fiberboard in strength and appearance but cost more. For budget projects, standard composite materials are suitable, for critical constructions it is better to choose sheet materials with improved characteristics.