Modern house construction requires a responsible approach to material selection. In 2025, the cellular concrete market is valued at $438.2 million with a projected growth of 5.3% annually. Aerated concrete or foam concrete — one of the most pressing questions for developers, as the comfort and durability of the future home depends on the right choice.

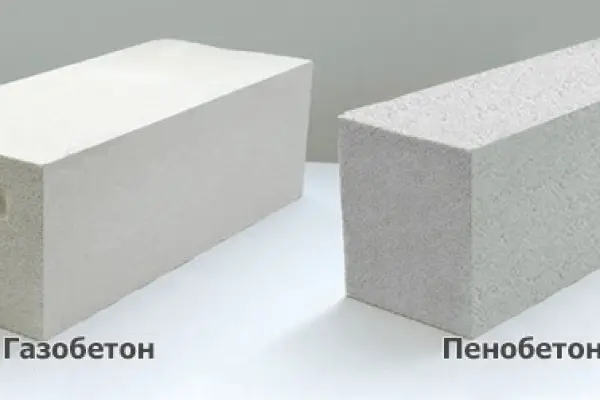

Both materials belong to lightweight concrete. The production technology of aerated concrete and foam concrete differs fundamentally. This affects all operational characteristics of the finished blocks.

Production Technology: Autoclaved Aerated Concrete vs Non-Autoclaved Foam Concrete

Understanding the manufacturing process — the key to the right choice. Autoclaved aerated concrete is produced in large factories using high-tech equipment. Aluminum powder is used as a foaming agent, which enters into a chemical reaction with lime.

Understanding the manufacturing process — the key to the right choice. Autoclaved aerated concrete is produced in large factories using high-tech equipment. Aluminum powder is used as a foaming agent, which enters into a chemical reaction with lime.

«During autoclaving, aerated concrete blocks are treated with steam at 12 atmospheres and a temperature of 200°C for 12 hours. This ensures high strength of aerated concrete and stability of the material structure» — notes process engineer Mikhail Petrov.

Non-autoclaved foam concrete is manufactured in a fundamentally different way. A foaming agent is added to the concrete mixture — often of organic origin. Hardening occurs naturally without expensive autoclaving. By the way, this allows the material to be produced even directly on the construction site.

Differences in production technology of aerated concrete and foam concrete determine all other properties of materials. Wire cutting ensures perfect geometry of aerated concrete blocks. Molding of foam concrete blocks is less precise.

Comparison of Physical and Mechanical Characteristics of Materials

A detailed comparison of aerated concrete and foam concrete shows significant differences. The choice is often made without understanding key parameters. Not always correctly. But correctable with competent analysis.

The main technical characteristics of aerated concrete and foam concrete are presented in the comparison table:

| Characteristic | Aerated Concrete | Foam Concrete |

|---|---|---|

| Density, kg/m³ | 300-700 | 600-1200 |

| Compressive strength, MPa | 2.5-5.0 | 1.0-2.5 |

| Thermal conductivity, W/m°C | 0.08-0.14 | 0.15-0.30 |

| Water absorption, % | 10-15 | 20-25 |

| Frost resistance, cycles | 50-100 | 25-50 |

The data meets the requirements of the ASTM C1693-11(2017) standard for autoclaved aerated concrete and shows the superiority of aerated concrete in most technical parameters.

Strength and Load-Bearing Capacity

The strength of aerated concrete at equal density is 1.5-2 times higher than foam concrete. Autoclaving forms a crystalline lattice identical to natural minerals. It's like turning ordinary sand into strong quartz under the pressure of time and temperature.

Shrinkage of aerated concrete is less than 0.5 mm/m. Shrinkage of foam concrete reaches 3 mm/m, which is critically important for load-bearing walls and can cause the appearance of cracks in aerated concrete or structural deformation. The strength of foam concrete decreases when the production technology is violated.

Thermal Insulation Properties

The thermal conductivity of aerated concrete is significantly lower due to its uniform porous structure. Pores with a diameter of 1-3 mm create an effective thermal barrier, providing excellent thermal insulation. According to research on thermal characteristics of cellular concretes, aerated concrete demonstrates stable performance in various climatic conditions. The thermal conductivity of foam concrete is almost twice as high.

The main advantages of aerated concrete thermal insulation include:

- Low thermal conductivity 0.08-0.14 W/m°C versus 0.15-0.30 for foam concrete

- No thermal bridges with thin-joint masonry on adhesive

- Stability of characteristics with humidity changes

- Possibility of building single-layer walls without additional facade insulation

Last season I encountered a cottage project near Kiev. Replacing foam concrete with aerated concrete allowed reducing the wall thickness from 40 to 30 cm while maintaining the required thermal resistance.

«An aerated concrete wall 30 cm thick is equivalent in thermal resistance to a brick wall 80 cm thick. At the same time, the load on the foundation is reduced by 30%» — research data from the Institute of Building Physics.

Sound Insulation and Vapor Permeability

The sound insulation of aerated concrete exceeds similar indicators of foam concrete. The dense structure of the autoclaved material effectively absorbs sound waves. The sound insulation of foam concrete depends on the quality of production and can vary significantly.

The vapor permeability of aerated concrete is 0.20-0.23 mg/(m·h·Pa). The vapor permeability of foam concrete is lower — 0.11-0.26 mg/(m·h·Pa) due to closed pores, which may require additional ventilation in energy-efficient homes.

Moisture Resistance and Vapor Permeability of Blocks

Water absorption of aerated concrete is 10-15% by mass. Foam concrete absorbs more moisture — up to 25%. This is related to the pore structure: in aerated concrete they are interconnected, in foam concrete — predominantly closed.

The vapor permeability of aerated concrete is higher. Walls «breathe», ensuring a comfortable microclimate. Foam concrete is less vapor permeable, which may require additional ventilation.

Practical Aspects of Construction Application

Aerated concrete blocks are easily processed with ordinary tools. Sawed with a saw, drilled with a drill, cut with a plane. Precise geometry allows the use of thin-joint masonry on adhesive.

Aerated concrete blocks are easily processed with ordinary tools. Sawed with a saw, drilled with a drill, cut with a plane. Precise geometry allows the use of thin-joint masonry on adhesive.

Foam concrete requires rougher processing. Structure heterogeneity can lead to chipping when cutting. Masonry is carried out on ordinary mortar with thick joints.

«In 2020 we built a house from D400 aerated concrete. We chose autoclaved blocks thanks to excellent thermal insulation. 30 cm walls without insulation provide comfort even at -25°C. Heating costs are 35% lower than neighbors with a brick house. The only minus — quality waterproofing of the basement was required» — shares experience developer Alexander K.

Block Sizes and Their Impact on Construction

Standard block sizes directly affect installation speed and masonry mortar consumption. Aerated concrete blocks are produced with precise geometry thanks to wire cutting on factory equipment. Honestly, this is one of the main factors determining the quality of finished masonry.

Popular aerated concrete block formats for low-rise construction:

- 600×200×300 mm — universal size for load-bearing walls

- 600×250×400 mm — for accelerated construction of large-format structures

- 600×100×250 mm — lightweight partition blocks for interior walls

Foam blocks have less precise geometry due to molding in metal forms. Deviations reach 3-5 mm, which increases joint thickness and mortar consumption when laying on mortar.

Leading Manufacturers of Aerated Concrete and Foam Concrete

Block quality depends on the manufacturer and strict adherence to technology. Where to buy aerated concrete or foam concrete — a question no less important than choosing the material itself.

Proven aerated concrete manufacturers in the international market:

- YTONG — German brand with factories in Europe, benchmark for autoclaved aerated concrete quality

- Bonolit — large manufacturer with modern technological lines

- AEROC — Belgian company specializing in energy-efficient solutions

- Hebel — Australian brand with global presence

Foam concrete manufacturers are represented mainly by local enterprises. Quality can vary significantly depending on equipment and production control. By the way, this is why when choosing foam concrete it is especially important to require quality certificates and check the supplier's reputation.

Masonry Mortars and Adhesive Compositions for Aerated Concrete and Foam Concrete

Aerated concrete is laid on special adhesive 2-3 mm thick. This eliminates thermal bridges and speeds up work. Adhesive consumption is 20-25 kg per cubic meter of blocks.

Aerated concrete is laid on special adhesive 2-3 mm thick. This eliminates thermal bridges and speeds up work. Adhesive consumption is 20-25 kg per cubic meter of blocks.

Foam concrete is installed on ordinary cement-sand mortar 10-15 mm thick. Mortar consumption is significantly higher — up to 40 kg per cubic meter.

Economic Component: Complete Cost Comparison

The cost of foam concrete is 15-20% lower than aerated concrete. However, total costs include additional expenses.

| Expense Item | Aerated Concrete ($/m³) | Foam Concrete ($/m³) |

|---|---|---|

| Block cost | 80-120 | 60-95 |

| Masonry material | 15-20 | 25-35 |

| Masonry work | 40-50 | 45-60 |

| Total per m³ in wall | 135-190 | 130-190 |

With comprehensive calculation, the difference in material costs is offset by additional expenses for foam concrete.

Durability and Operational Qualities

Aerated concrete demonstrates high durability. Houses over 70 years old are operated in the Baltics without signs of destruction. Seismic resistance is also impressive — buildings in Norilsk have been serving for over 40 years.

Frost resistance of aerated concrete is 50-100 cycles, foam concrete — 25-50. This determines service life in variable climate conditions.

«Autoclaving gives aerated concrete the stability of natural stone. With proper design and installation, the service life is 100+ years» — states the leading structural engineer of the «StroyProekt» design institute.

Environmental Aspects and Safety

Both materials are environmentally safe. Aerated concrete consists of mineral components: cement, lime, sand, aluminum powder. Industrial waste is sometimes used in production — ash and slags.

Foam concrete requires foaming agents, which can be synthetic. Organic additives are preferable from an environmental standpoint.

Applications: Aerated Concrete vs Foam Concrete

Aerated concrete is ideal for load-bearing walls of low-rise buildings. Grades D400-D500 are used for insulation, D500-D600 — for load-bearing structures. Excellent thermal insulation makes it the #1 choice for energy-efficient homes.

Foam concrete is more often used for partition blocks, monolithic construction, floor pouring. Increased moisture resistance allows its use in basements and technical rooms.

How to Choose Material: Step-by-Step Recommendations

Choosing between aerated concrete and foam concrete requires analysis of several key factors.

Step-by-step selection algorithm:

- Determine the purpose — load-bearing walls, partitions or insulation

- Calculate thermal resistance requirements for your region

- Assess budget considering full work cost

- Check availability of quality manufacturers in the region

- Consider construction timeframes and builder qualifications

How to Check Block Quality When Purchasing

Visual inspection of blocks allows identifying major defects before purchase. Last year I consulted a developer who saved $2000 by refusing a batch of poor-quality foam concrete after thorough inspection.

Visual inspection of blocks allows identifying major defects before purchase. Last year I consulted a developer who saved $2000 by refusing a batch of poor-quality foam concrete after thorough inspection.

Block quality assessment criteria:

- Geometry — deviations no more than 2 mm in length and height for aerated concrete

- Color — aerated concrete should be white, foam concrete gray, without spots and streaks

- Pore structure — in aerated concrete small and uniform, in foam concrete larger and may be heterogeneous

- No chips, microcracks in aerated concrete and crumbling corners

- Foam concrete density should match the declared grade

Be sure to require quality certificates and test protocols. Documents — guarantee of characteristic compliance.

Summary for Developers: Selection by Criteria

| Selection Criterion | Recommendation | Justification |

|---|---|---|

| Energy-efficient house | Aerated concrete D400-D500 | Best thermal insulation |

| Limited budget | Foam concrete D600-D800 | Lower material cost |

| Fast construction | Aerated concrete | Precise geometry, thin joints |

| Humid climate | Foam concrete | Less water absorption |

| Self-construction | Aerated concrete | Easier processing and installation |

The final choice should consider a complex of factors and specific project conditions.

When choosing wall material, be guided by specific project conditions. Aerated concrete — optimal choice for energy-efficient private homes, foam concrete — economical solution for technical buildings. Quality construction is possible with either of these materials when technology is followed.