Wastewater treatment is becoming a critically important process in the context of global water resource scarcity and increasing environmental pressure. According to the UN, more than 80% of the world's wastewater is discharged without adequate treatment, endangering the health of 1.8 billion people. Modern wastewater treatment technologies effectively address this problem by removing contaminants and returning purified water to the natural cycle. Incidentally, the water treatment technology market is showing steady growth - from $217 billion in 2023 to a projected $300 billion by 2030.

Before constructing a treatment system, whether for a cottage community or an industrial enterprise, it is critically important to study wastewater treatment methods suitable for the specific situation. Have you ever wondered how much effort it takes to keep the water from our taps clean? Each method has its advantages and limitations. Well-designed treatment facilities ensure not only compliance with environmental standards but also substantial resource savings in the long term.

Key Methods of Wastewater Treatment: From Simple to Innovative

The choice of treatment technology directly depends on the composition of wastewater, the required degree of purification, and local conditions. There is no universal solution. Often the best result is achieved by combining several technologies, including wastewater disinfection systems at the final stage.

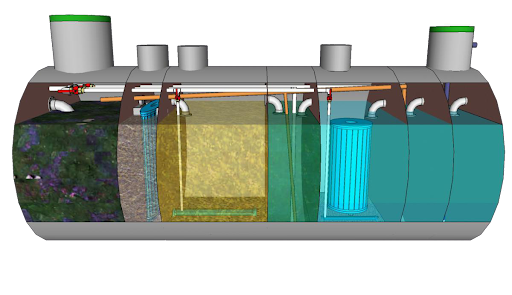

Mechanical Wastewater Treatment: The First Barrier for Contaminants

Mechanical wastewater treatment represents the primary stage of processing, where large solid particles and suspended substances are removed. The process is simple. Depending on the type of contaminants, the effectiveness of this method can reach 60-70%. During a visit to treatment facilities in Warsaw, I was impressed by how thoroughly the sequence of mechanical filters of varying degrees of purification was designed.

Mechanical wastewater treatment represents the primary stage of processing, where large solid particles and suspended substances are removed. The process is simple. Depending on the type of contaminants, the effectiveness of this method can reach 60-70%. During a visit to treatment facilities in Warsaw, I was impressed by how thoroughly the sequence of mechanical filters of varying degrees of purification was designed.

First, the effluent passes through screens that capture large debris larger than 5-10 mm. Modern mechanized screens are equipped with automatic cleaning systems, which reduces labor costs and increases reliability. After this, the water is directed to grit chambers, where sand and mineral particles settle. Industrial systems also use grease traps and oil traps to remove floating contaminants.

According to the experience of leading industry experts, quality mechanical treatment can significantly reduce the load on subsequent processing stages and increase equipment service life. Special attention should be paid to the proper design of settling tanks - too high flow velocity reduces sedimentation efficiency, while too low flow velocity provokes silting.

The final stage of mechanical treatment is settling in primary sedimentation tanks, where phase separation occurs under the influence of gravity. This process resembles the settling of cloudy water in a glass - all excess gradually settles to the bottom. Advanced horizontal settlers with thin-layer modules allow intensifying the process and reducing the area of structures by up to 30% compared to classic designs.

Biological Wastewater Treatment: Natural Mechanisms in the Service of Ecology

Biological wastewater treatment is based on the ability of microorganisms to decompose organic contaminants, converting them into harmless compounds. Amazing, isn't it? This is the most environmentally friendly and cost-effective method for removing dissolved organic substances. When properly operated, biological systems provide a purification degree of up to 90-98%.

Biological wastewater treatment is based on the ability of microorganisms to decompose organic contaminants, converting them into harmless compounds. Amazing, isn't it? This is the most environmentally friendly and cost-effective method for removing dissolved organic substances. When properly operated, biological systems provide a purification degree of up to 90-98%.

The technology is based on aerobic and anaerobic processes. Aerobic treatment occurs in the presence of oxygen, which is supplied to the system through aeration devices. The main working element is activated sludge - a complex community of microorganisms that oxidize contaminants. To be honest, the effectiveness of the biological method heavily depends on environmental conditions - temperature, pH, oxygen content, and the presence of toxic substances.

| Parameter | Aerobic treatment | Anaerobic treatment |

|---|---|---|

| Energy consumption | High (for aeration) | Low |

| Process speed | High | Low |

| Sludge formation | Significant (40-60% of initial BOD) | Minimal (5-10% of initial BOD) |

| Resistance to toxins | Low | Medium |

| Temperature requirements | Moderate (8-35°C) | High (30-60°C) |

| Pathogen removal | Effective | Partial |

| Energy production | No | Biogas (methane) |

| Typical application | Domestic wastewater, low BOD effluents | Highly concentrated industrial effluents |

The table clearly demonstrates that the choice between aerobic and anaerobic processes should take into account numerous factors, including economic and environmental aspects. In modern practice, combined schemes are often used, maximizing the advantages of both approaches.

Highly efficient plug-flow aeration tanks with nitrification and denitrification allow removing not only organic substances but also nitrogen compounds. And biological phosphorus removal reduces the need for expensive reagents. Industrial practice also uses biofilters, where microorganisms are fixed on an inert carrier, which increases their resistance to surge discharges.

"In our city, the implementation of modern biological treatment with membrane bioreactors allowed us not only to achieve standards for discharge into a fishery water body but also to revive a river that was previously considered hopelessly polluted. Three years after the modernization of treatment facilities, 15 species of fish returned to the reservoir, and the shores became a popular recreation spot. With investments of $8.5 million, we received not only an environmental but also an economic effect - a 23% reduction in operating costs thanks to energy-efficient equipment and less sludge formation requiring disposal," shares Alex Morgan, Technical Director of the Greenville Municipal Water Utility.

Physicochemical Wastewater Treatment: Advanced Technologies for Complex Tasks

Physicochemical methods of wastewater treatment are applied as independent technologies or in combination with other processes to remove specific contaminants. These methods are particularly effective in treating industrial effluents containing heavy metals, petroleum products, and other difficult-to-degrade substances.

Physicochemical methods of wastewater treatment are applied as independent technologies or in combination with other processes to remove specific contaminants. These methods are particularly effective in treating industrial effluents containing heavy metals, petroleum products, and other difficult-to-degrade substances.

The main physicochemical methods used in modern water treatment include:

- Coagulation and flocculation - processes of aggregating fine particles

- Sorption on activated carbon and other sorbents

- Flotation and electroflotation for removing floating contaminants

- Ion exchange - removal of dissolved heavy metal ions

- Extraction - retrieval of valuable or toxic components

- Membrane processes - ultrafiltration, nanofiltration, and reverse osmosis

- Electrodialysis - membrane separation under the influence of an electric field

- Ozonation and oxidation - destruction of difficult-to-degrade organic compounds

Each of the listed methods has its own application area and degree of effectiveness, determining its place in the technological scheme of treatment facilities.

Coagulation and flocculation allow collecting fine-dispersed and colloidal particles into larger aggregates, which are then separated by settling or flotation. To increase efficiency, modern coagulants based on polyaluminum chloride and organic flocculants are used. It's like turning a cloud of dust into pebbles - the process makes the invisible visible and easily extractable.

Flotation and electroflotation ensure the removal of suspended substances, fats, and petroleum products by adhesion of particles to air bubbles and their rise to the surface. In industrial systems, pressure flotation with recirculation is often used, providing high efficiency with compact installation dimensions.

One of the most promising modern technologies for wastewater treatment is membrane processes - ultrafiltration and reverse osmosis. At facilities in Singapore and Australia, I observed how effective these methods are for removing dissolved substances, including salts and micropollutants. Reverse osmosis systems provide water quality approaching distilled, allowing it to be returned to the technological cycle.

| Type of contaminants | Mechanical treatment | Biological treatment | Physicochemical treatment | Combined methods |

|---|---|---|---|---|

| Suspended substances | 60-90% | 70-95% | 80-98% | 95-99% |

| Organic contaminants (BOD) | 20-30% | 90-98% | 40-70% | 95-99% |

| Nitrogen | 5-10% | 70-90% | 30-40% | 80-95% |

| Phosphorus | 5-10% | 30-50% | 80-95% | 90-98% |

| Petroleum products | 40-60% | 60-80% | 85-98% | 95-99% |

| Heavy metals | 5-30% | 10-30% | 80-98% | 90-99% |

| Bacteria and pathogens | 10-20% | 90-95% | 99-99.9% | 99.9-99.99% |

This table demonstrates that to achieve high purification indicators for all parameters, it is necessary to apply combined methods, sequentially removing different types of contaminants. This confirms the importance of a comprehensive approach to the design of treatment facilities.

Various methods are used for disinfecting treated wastewater, including chlorination, ozonation, and ultraviolet irradiation. The modern trend is the abandonment of chlorination in favor of UV disinfection and electrochemical disinfection, which do not form toxic by-products and are effective against a wide spectrum of pathogens. In my experience, the combination of UV irradiation with preliminary fine filtration provides the optimal ratio of cost and disinfection effectiveness.

Innovative Wastewater Treatment Systems: A Modern Approach

Wastewater treatment technologies do not stand still - new solutions are constantly emerging that increase the efficiency and environmental friendliness of processes. Best available technologies (BAT) in water treatment are being particularly actively implemented, providing an optimal ratio of environmental and economic indicators. Last year, more than 200 new developments in this field were presented at the environmental technology exhibition in Munich.

Membrane Bioreactors (MBR): A Revolution in Biological Treatment

Membrane bioreactors combine biological treatment with ultrafiltration membranes, replacing secondary settling tanks. This allows increasing the concentration of activated sludge to 10-15 g/l (versus 3-4 g/l in traditional aeration tanks), reducing the volume of facilities, and improving treatment quality. MBR technologies ensure almost complete removal of suspended substances and reliable removal of bacteria without additional disinfection.

Membrane bioreactors combine biological treatment with ultrafiltration membranes, replacing secondary settling tanks. This allows increasing the concentration of activated sludge to 10-15 g/l (versus 3-4 g/l in traditional aeration tanks), reducing the volume of facilities, and improving treatment quality. MBR technologies ensure almost complete removal of suspended substances and reliable removal of bacteria without additional disinfection.

According to a study published in the scientific journal Membranes (Ezugbe & Rathilal, 2020), membrane technologies have become the preferred choice for water recycling from various wastewaters due to their high efficiency and compactness. The authors note the following key advantages of membrane systems in wastewater treatment:

- High degree of purification - removal of up to 99% of contaminants, including microplastics and pharmaceutical residues

- Significant reduction in the area of treatment facilities by 60-70%

- Possibility of modular expansion in accordance with growing needs

- Process automation and stability of treated water quality

- Effective removal of pathogenic microorganisms without the use of chemical disinfectants

- Possibility of selective removal of contaminants depending on the type of membranes used

However, the implementation of membrane technologies is associated with certain challenges, such as membrane fouling, increased energy consumption, and the need for regular membrane cleaning. These factors must be taken into account when designing and operating such systems.

According to an international study conducted in 2024, the use of MBR allows reducing the area of treatment facilities by 60-70% while simultaneously improving treatment quality. Not always simple. But effective. The main limitation remains the cost of membrane modules and increased energy consumption.

Anaerobic Water Treatment Technologies and Biogas Production

Anaerobic treatment of highly concentrated wastewater from food, alcohol, and other industries allows not only neutralizing effluents but also obtaining a valuable energy carrier - biogas. Imagine - waste turns into energy! Modern UASB reactors (Upflow Anaerobic Sludge Blanket reactors) and ICX technologies (Internal Circulation anaerobic reactors) provide high process speed and resistance to fluctuations in effluent composition.

Anaerobic treatment of highly concentrated wastewater from food, alcohol, and other industries allows not only neutralizing effluents but also obtaining a valuable energy carrier - biogas. Imagine - waste turns into energy! Modern UASB reactors (Upflow Anaerobic Sludge Blanket reactors) and ICX technologies (Internal Circulation anaerobic reactors) provide high process speed and resistance to fluctuations in effluent composition.

In European practice, anaerobic treatment allows covering up to 30% of the energy consumption of treatment facilities through own electricity generation from biogas. This is especially relevant in conditions of rising energy tariffs.

To ensure stable operation of anaerobic reactors, it is important to carefully control process parameters - temperature, pH, redox potential. It is also recommended to provide systems for biogas collection and utilization, including gas holders, hydrogen sulfide removal systems, and cogeneration units for efficient production of thermal and electrical energy.

Technologies for Removing Biogenic Elements from Water

Excessive content of nitrogen and phosphorus in wastewater leads to eutrophication of water bodies - rapid development of algae and disruption of ecological balance. Modern wastewater treatment technologies include nitrification-denitrification processes for nitrogen removal and biological or reagent removal of phosphorus.

Excessive content of nitrogen and phosphorus in wastewater leads to eutrophication of water bodies - rapid development of algae and disruption of ecological balance. Modern wastewater treatment technologies include nitrification-denitrification processes for nitrogen removal and biological or reagent removal of phosphorus.

The nitrification process is carried out by aerobic bacteria that oxidize ammonium nitrogen to nitrites and nitrates. Then, under anoxic conditions (in the presence of bound oxygen), denitrification occurs - the reduction of nitrates to molecular nitrogen. You can imagine this as a chain of chemical transformations where harmful is converted to harmless. This complex process allows effectively removing nitrogen compounds, preventing water body pollution.

For phosphorus removal, biological accumulation in the cells of phosphorus-accumulating organisms or chemical precipitation using reagents is used. In advanced practice, these methods are often combined to achieve maximum efficiency at minimum cost.

Economic and Environmental Aspects of Wastewater Treatment

The choice of wastewater treatment technology should take into account not only technical but also economic aspects. It is necessary to evaluate both capital construction costs and operational expenses throughout the entire life cycle of the facilities.

For a cottage community of 50 houses, the installation cost can vary from $15,000 for simple biological systems to $50,000 or more for complex physicochemical solutions. At the same time, annual operating costs are 10-15% of capital investments. In my practice of consulting on the selection of treatment systems for suburban settlements, the most optimal option often turned out to be compact biological treatment plants with membrane elements, providing high quality treatment at moderate costs.

A study published in the Journal of Cleaner Production (Dutta, Arya & Kumar, 2021) highlights key challenges and best practices in industrial wastewater treatment. The study authors note the following trends and recommendations:

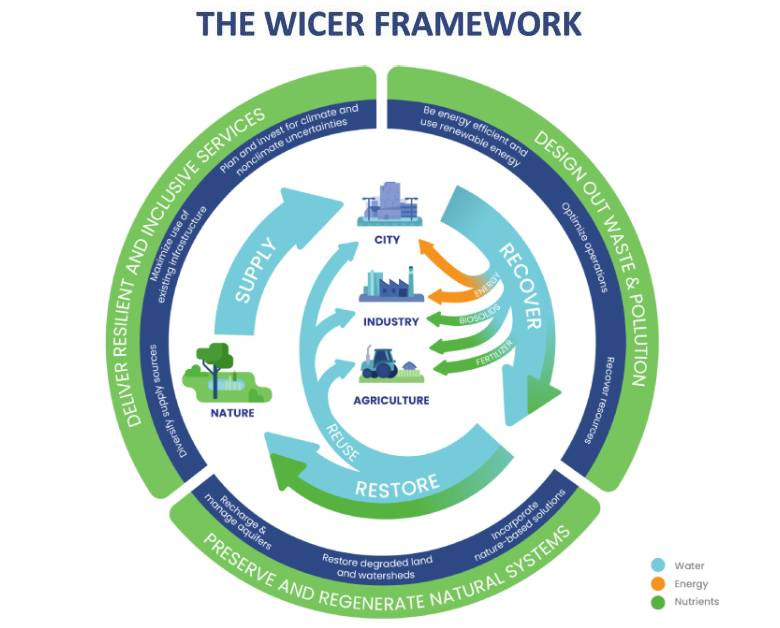

- Transition from "end-of-pipe" to integrated wastewater management throughout the production cycle

- Application of circular economy principles, where wastewater is viewed as a resource for extracting valuable components

- Development of specific solutions for each type of industry, taking into account the peculiarities of their effluents

- Hybridization of different treatment technologies to achieve a synergistic effect

- Minimization of waste generation in the wastewater treatment process

- Optimization of energy consumption of treatment systems, including the use of renewable energy sources

- Implementation of digital monitoring and management technologies to optimize treatment processes

Taking these factors into account when designing and operating treatment facilities allows significantly increasing their efficiency and reducing environmental impact.

The most important factor is the possibility of reusing treated wastewater, which is especially relevant in regions with water resource scarcity. Deep post-treatment technologies, including membrane processes and disinfection, allow preparing water for technical needs, irrigation, or even replenishing underground aquifers.

Sustainable Water Use and Circular Economy

The modern approach to wastewater treatment includes the concept of circular economy, where effluents are viewed not as waste but as a resource. This always reminds me of the philosophy "there is no waste, only resources in the wrong place." This approach involves extracting valuable components (phosphorus, nitrogen), obtaining energy (biogas), and reusing treated water.

The modern approach to wastewater treatment includes the concept of circular economy, where effluents are viewed not as waste but as a resource. This always reminds me of the philosophy "there is no waste, only resources in the wrong place." This approach involves extracting valuable components (phosphorus, nitrogen), obtaining energy (biogas), and reusing treated water.

"In our city, the implementation of modern biological treatment with membrane bioreactors allowed us not only to achieve standards for discharge into a fishery water body but also to revive a river that was previously considered hopelessly polluted. Three years after the modernization of treatment facilities, 15 species of fish returned to the reservoir, and the shores became a popular recreation spot. With investments of $8.5 million, we received not only an environmental but also an economic effect - a 23% reduction in operating costs thanks to energy-efficient equipment and less sludge formation requiring disposal," shares Alex Morgan, Technical Director of the Greenville Municipal Water Utility.

One of the most striking examples of sustainable water use is the city of Windhoek (Namibia), where a unique wastewater treatment system has been functioning since 1968, converting it into drinking water. Due to chronic water shortage, the city implemented a multi-stage treatment technology, including ultrafiltration, reverse osmosis, and ultraviolet disinfection. Daily, 21,000 m³ of wastewater is transformed into water safe for drinking, providing 35% of the city's needs. The project has proven that water recycling can be a sustainable solution for regions with resource scarcity, inspiring similar initiatives in Australia and the USA.

In Singapore, the NEWater program demonstrates the successful application of this approach - up to 40% of wastewater undergoes deep treatment and returns to the water management cycle. The program works like clockwork. In the coming years, this share is planned to increase to 55%.

Legal Aspects and Wastewater Discharge Standards

When designing wastewater treatment systems, it is necessary to take into account current norms and regulations. For small systems with a capacity of up to 5-7.5 m³/day, notification of local authorities is often sufficient, while for larger facilities, obtaining special permits is required.

Wastewater discharge standards in different countries vary significantly, but the general trend is towards tightening requirements for the quality of treated effluents. Incidentally, the strictest standards are in Switzerland, Germany, and Singapore, where requirements for treated effluents are close to drinking water standards for a number of indicators.

It is important to comply with the quality standards of treated effluents, which differ depending on the category of the receiving water body. Particularly strict requirements are imposed when discharging into fishery water bodies - here, deep post-treatment with the use of membrane technologies and modular treatment systems for final water polishing is often necessary.

Installation and Maintenance of Wastewater Treatment Systems

Professional installation of treatment facilities is critically important for their reliable and efficient operation. After selecting the technology, a project is developed and component equipment is selected, taking into account the specifics of the particular facility. The supply of water treatment equipment should be carried out by reliable companies with good reputations, providing warranty and service maintenance.

Professional installation of treatment facilities is critically important for their reliable and efficient operation. After selecting the technology, a project is developed and component equipment is selected, taking into account the specifics of the particular facility. The supply of water treatment equipment should be carried out by reliable companies with good reputations, providing warranty and service maintenance.

Earthworks and reservoir installation should be performed in compliance with construction standards, including requirements for waterproofing and protection against flotation in case of high groundwater levels. Special attention is paid to pipeline laying with compliance to slopes and installation of pumping equipment.

Wastewater treatment systems require regular maintenance, including control of technological parameters, replacement of consumables, sampling, and analysis. For biological systems, control of activated sludge condition and maintenance of optimal conditions for its functioning are especially important. The frequency of technical maintenance of local treatment facilities ranges from once every 3 months to once a year, depending on the type of system and intensity of operation.

Promising Directions in the Development of Treatment Technologies

Wastewater treatment technologies are constantly being improved, adapting to new challenges and opportunities. One of the key trends is the implementation of digital technologies and automation, allowing optimization of treatment facilities operation in real-time.

Innovative approaches shaping the future of water treatment include:

- Intelligent management systems based on artificial intelligence

- Nanomaterials for next-generation membranes with improved characteristics

- Biomimetic technologies mimicking natural purification processes

- Ecological solutions - constructed wetlands and phytoremediation

- Algochemical method using microalgae for extracting biogenic elements

- Advanced oxidation processes (AOP) for destroying persistent organic pollutants

- Electrochemical treatment systems with low energy consumption

- Technologies for extracting valuable resources from wastewater sludge

These promising directions not only increase treatment efficiency but also contribute to more sustainable use of water resources and reduce environmental impact.

Intelligent management systems based on artificial intelligence analyze the parameters of incoming effluents and adjust reagent dosing, aeration intensity, and other parameters. According to consulting company McKinsey, such systems can reduce energy consumption of treatment facilities by 10-20% and increase productivity by 15-25%. Already today, automation of water treatment systems allows significantly reducing operating costs and increasing equipment operation stability.

The second important direction is the development of ecological technologies that use the potential of natural processes. Constructed wetlands, phytoremediation, algochemical method using microalgae - all these approaches allow treating wastewater with minimal environmental impact.

When planning treatment facilities, it is necessary to consider them as an integral part of the ecosystem, not just as engineering objects. The biomimetic approach, imitating natural processes, allows creating sustainable and energy-efficient systems that not only clean water but also restore natural balance. The key principle is to work with nature, not against it.

It is also worth noting the development of technologies for wastewater sludge utilization - a problem that remains relevant for most treatment facilities. Modern approaches include the production of biocomposts, vermiculture, thermal treatment with biochar production, and extraction of valuable components such as phosphorus for fertilizer production.

Conclusion: A Comprehensive Approach to Wastewater Treatment

Selecting the optimal wastewater treatment technology requires comprehensive analysis of multiple factors - from effluent composition and required degree of purification to economic and environmental aspects. Universal solutions do not exist - each project should be developed individually, taking into account local conditions and development prospects.

Modern wastewater treatment technologies open wide opportunities for protecting water resources, water reuse, and extracting valuable components. Their implementation is not just a technical task but also an important step towards sustainable development, preserving natural resources for future generations.

Investments in effective wastewater treatment systems pay off not only in direct economic benefits but also in preventing environmental damage, improving quality of life, and ensuring access to clean water - a basic condition for sustainable development of society.