Technological soundproofing materials in 2025 open new possibilities for combating noise. Modern soundproofing materials based on nanotechnology and smart materials can block up to 94% of unwanted sounds. Innovative soundproofing materials, including acoustic metamaterials and smart soundproofing materials, cost from $25-30 per square meter and demonstrate a sound absorption coefficient of up to 0.95 in optimal frequency ranges.

The global soundproofing market reached $18.4 billion in 2023, according to Grand View Research. Demand for solutions ensuring acoustic comfort in apartments is growing. Over 1 billion people suffer from urban noise, as confirmed by WHO: noise exposure is linked to cardiovascular diseases, mental health issues, and sleep disturbances. This drives the development of cutting-edge soundproofing technologies and noise reduction in residential spaces. *Prices are indicated for the US/Europe market.

In my practice with private clients, I notice: apartment owners are willing to pay 40% more for technological soundproofing systems if they reduce noise below 30 dB — the threshold for comfortable sleep.

Solving the Problem of Neighbor Noise: Practical Approaches

Addressing neighbor noise requires a comprehensive approach to acoustic insulation. By the way, according to a WHO study, most complaints about discomfort in multi-apartment buildings are related to neighbor noise. Soundproofing thin walls in Soviet-era panel buildings becomes a priority during renovations.

Addressing neighbor noise requires a comprehensive approach to acoustic insulation. By the way, according to a WHO study, most complaints about discomfort in multi-apartment buildings are related to neighbor noise. Soundproofing thin walls in Soviet-era panel buildings becomes a priority during renovations.

Protection against impact noise is particularly relevant for lower floors. In my work with private clients, I often encounter situations where the thickness of inter-apartment walls in panel buildings is only 120-160 mm, which is insufficient for modern acoustic comfort standards.

Effective solutions include:

- Installing soundproofing on walls adjacent to neighboring apartments

- Using vibration-isolating mounts for ceiling structures

- Floor soundproofing under screed to protect downstairs neighbors

- Sealing all technological openings and joints

The result of a proper approach — professional systems can reduce noise levels from 65-70 dB to a comfortable 35-40 dB, significantly improving quality of life in multi-apartment buildings.

International Standards and Norms for Acoustic Insulation

International standards define requirements for acoustic comfort in buildings. ISO 12354 establishes methods for calculating sound insulation, while ISO 717 regulates the evaluation of airborne sound insulation for walls and floors. Why is this important for the average consumer?

The European standard EN 12354 requires a minimum sound insulation of DnTw ≥ 50 dB between apartments. The American standard ASTM E90 defines methods for measuring sound transmission loss. Compliance with international norms ensures the quality of soundproofing solutions and protects against overpaying for ineffective systems.

International regulations establish four key levels of acoustic comfort for different types of spaces:

- Bedrooms: maximum 30 dB (night), 35 dB (day) per WHO Guidelines

- Living rooms: up to 40 dB per ISO 1996-1

- Offices: 35-45 dB for focus and concentration

- Studios: below 25 dB for professional recording

Adhering to these standards ensures not only comfort but also protection from the adverse health effects of noise.

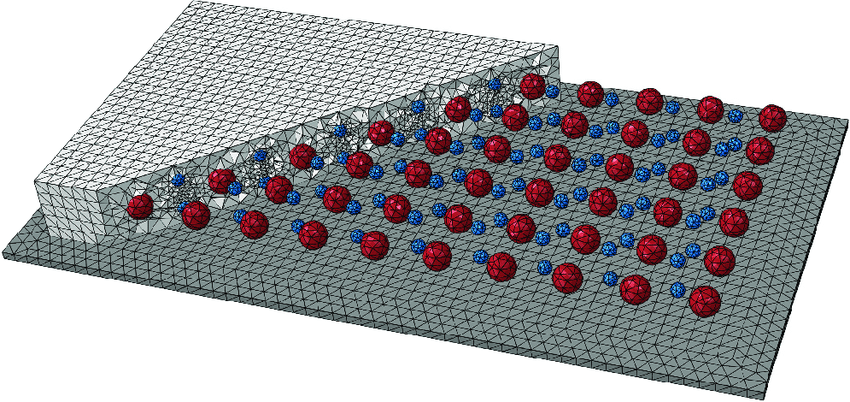

Revolutionary Acoustic Metamaterials

Revolutionary acoustic metamaterials represent a breakthrough in soundproofing. Not ordinary solutions. Artificially engineered structures with unique properties that natural materials do not exhibit — as if sound encounters an invisible wall.

Acoustic metamaterials can manipulate sound waves at a subwavelength level (sizes smaller than the sound wave’s wavelength), creating effects like "acoustic invisibility" or directional sound absorption. In one recent project, I saw firsthand: a 2 cm thick panel blocked office noise 25 dB more effectively than a traditional wall ten times thicker. These solutions work on the principle of resonant structures (a multitude of microscopic resonators, akin to musical tuning forks) — they absorb specific frequencies.

Researchers from Boston University developed a metamaterial just 3 cm thick that blocks 94% of noise while remaining air-permeable. According to The 2024 Acoustic Metamaterials Roadmap, such structures exhibit a sound transmission coefficient below 0.06 at critical frequencies. Production costs are around $120 per m². In a recent London project, these solutions were used to soundproof a recording studio, reducing noise from 65 to 25 dB.

Smart Materials: Intelligent Soundproofing Materials

Smart soundproofing materials adapt to environmental conditions. They change properties automatically. They respond to sound frequency, temperature, or electrical signals, optimizing sound absorption in real-time — like a chameleon changing color to blend into its surroundings.

Smart materials for soundproofing include four main directions for developing adaptive acoustic insulation:

- Piezoelectric panels generating counter-phase vibrations

- Programmable soundproofing materials with adjustable structures

- Magnetorheological fluids for vibration isolation

- Self-healing soundproofing materials

Each direction addresses specific adaptive soundproofing challenges depending on operating conditions. Thus, intelligent acoustic systems provide programmable noise insulation tailored to specific room conditions.

Panel building case: a 68 m² three-room apartment with issues from neighbor and elevator noise. Solution: 2 mm SoundGuard membrane + 50 mm mats + drywall. Budget $2800, result: noise reduction from 52 to 31 dB. Apartment value increased by $8200 due to comprehensive renovations, including soundproofing.

Nanotechnology in Soundproofing

Nanotechnology in soundproofing enables the creation of solutions with molecularly precise structures. Aerogels — ultralight nanostructured sound absorbers (products with nanometer-scale pores, like a sponge for molecules) — absorb up to 99% of sound waves at a density of just 0.1-0.5 kg/m³.

Nanotechnology in soundproofing enables the creation of solutions with molecularly precise structures. Aerogels — ultralight nanostructured sound absorbers (products with nanometer-scale pores, like a sponge for molecules) — absorb up to 99% of sound waves at a density of just 0.1-0.5 kg/m³.

Nanomaterials possess unique properties. Due to the structural features of nanostructures, high porosity is achieved while maintaining mechanical strength. Polymer nanofibers create a three-dimensional network of micropores (a structure like a spider web), effectively dissipating sound energy and achieving record-breaking noise reduction.

Physically cross-linked polyethylene soundproofing at the nanoscale demonstrates a sound absorption coefficient of 0.95 in the 500-4000 Hz range. In practice, I often notice: such solutions are particularly effective in studios where mid-frequency sound clarity is critical — like a finely tuned musical instrument.

Soundproofing Windows and Doors: Critical Points

Soundproofing windows and doors often determines the overall system’s effectiveness. Up to 80% of external noise penetrates through uninsulated openings, negating efforts to soundproof walls.

Soundproofing windows and doors often determines the overall system’s effectiveness. Up to 80% of external noise penetrates through uninsulated openings, negating efforts to soundproof walls.

Modern window solutions include multi-chamber double-glazed units with laminated glass. Triplex (multilayered glass with a polymer film) reduces noise penetration by 35-45 dB at a thickness of 6-12 mm. Window replacement costs $200-800 per m², depending on the class.

Soundproof doors with multilayered construction provide insulation up to 50 dB. Key elements: dense core, high-quality seals, and soft-closing mechanisms. Professional soundproof doors cost $300-1500 per unit.

Simple improvements to existing structures: replacing seals ($15-30), installing door closers ($25-60), and sealing gaps with acoustic sealant ($8-12 per tube).

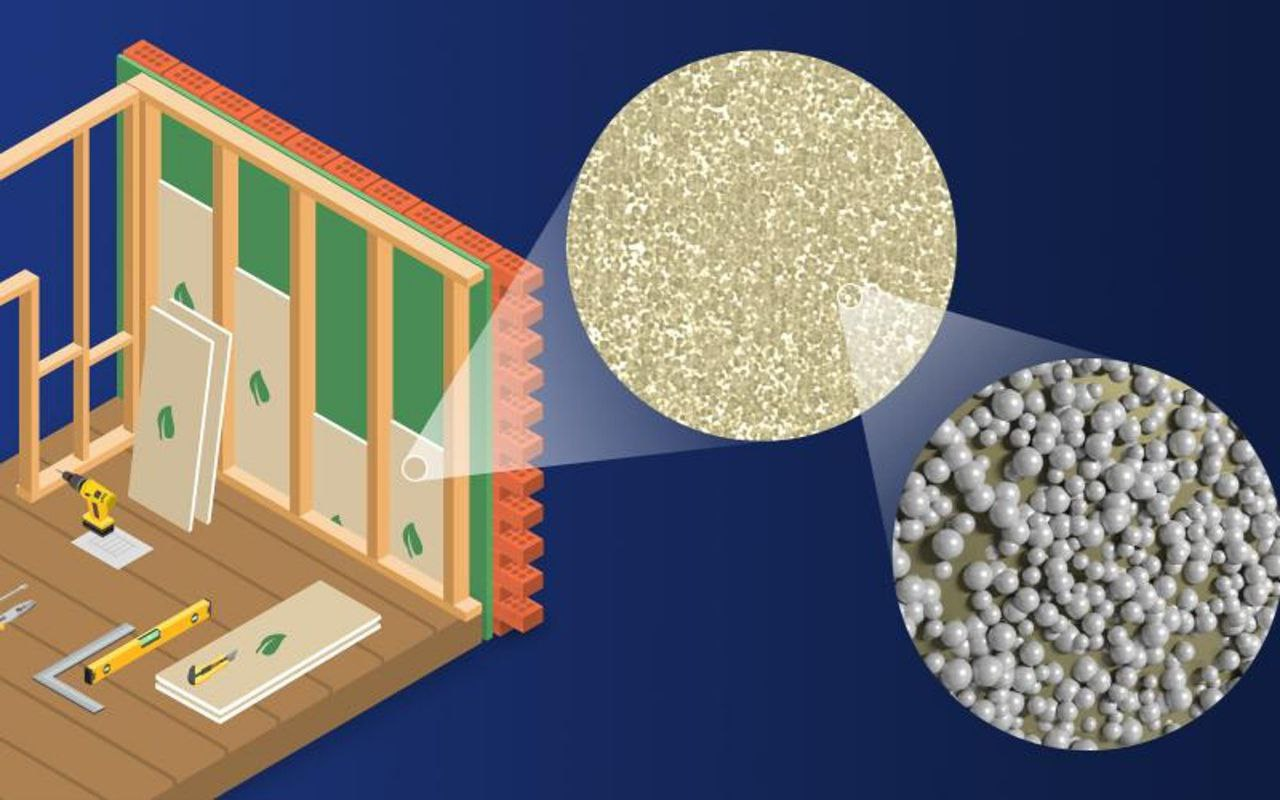

Hybrid Solutions: Sound and Thermal Insulation

Hybrid materials combine soundproofing and thermal insulation properties, which is particularly relevant for exterior walls. This approach saves space and reduces overall project costs by 20-30%.

Modern hybrid solutions include closed-cell polyurethane panels with microporous structures (thermal conductivity coefficient of 0.025 W/m·K, sound absorption of 0.85), aerogel composites for extreme conditions, and multilayer sandwich panels with reflective layers.

In practice, I often notice: a properly selected hybrid system addresses three tasks simultaneously — soundproofing, thermal insulation, and saving usable space.

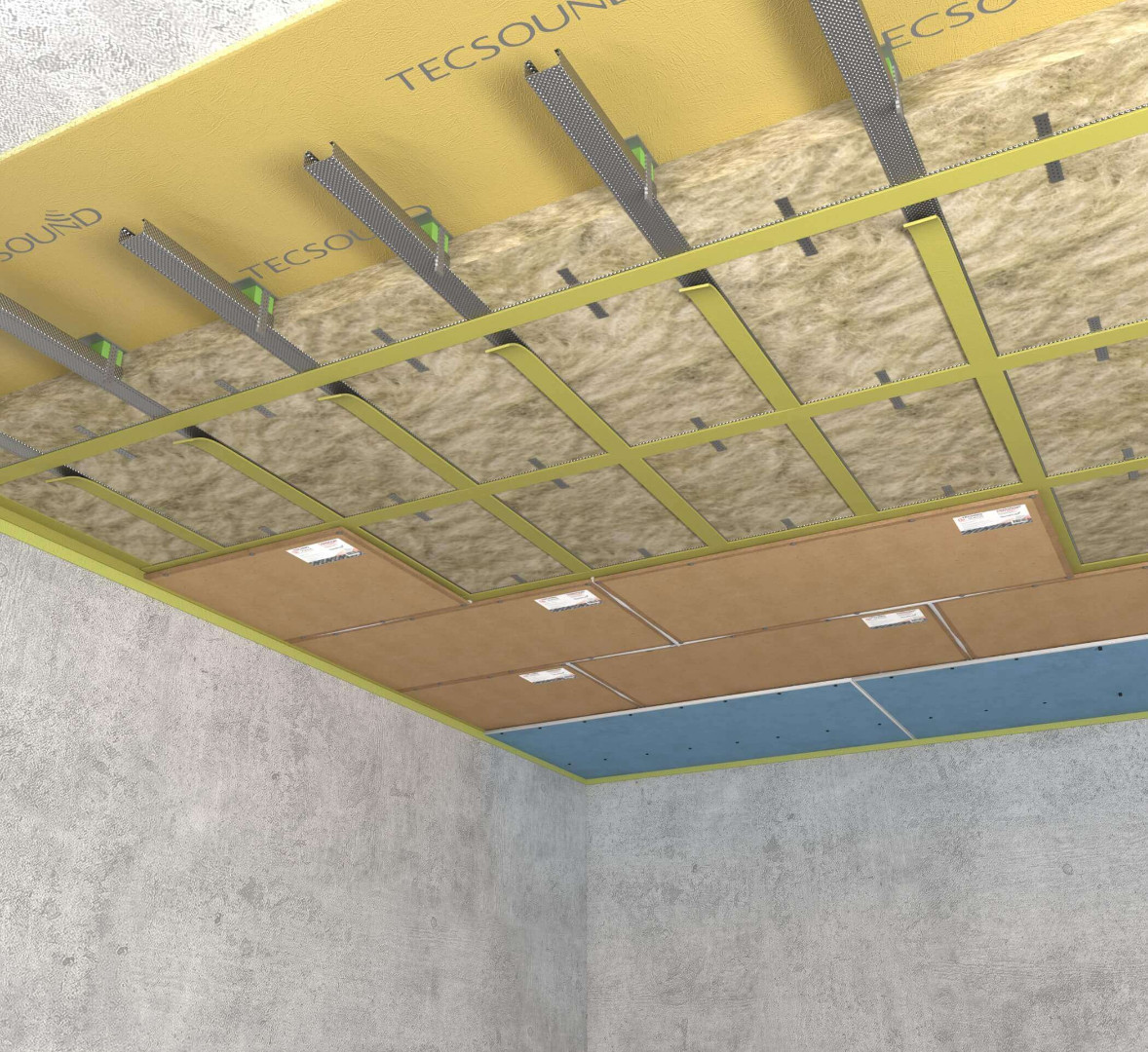

Modern Ceiling Soundproofing: 2025 Technologies

Modern ceiling soundproofing requires a specialized approach to installing acoustic insulation. Ceiling structures transmit up to 60% of impact noise from upstairs neighbors. How to solve this problem effectively?

Modern ceiling soundproofing requires a specialized approach to installing acoustic insulation. Ceiling structures transmit up to 60% of impact noise from upstairs neighbors. How to solve this problem effectively?

Advanced systems include suspended ceilings on vibration-isolated frames, multilayer soundproofing systems with air gaps, and specialized acoustic membranes for ceiling installation. Ceiling soundproofing thickness ranges from 80 to 200 mm, depending on required effectiveness.

In my work with private clients, ceiling acoustic insulation increases comfort by 70-80% when done correctly — the difference is like that between a noisy street and a quiet library.

Modern Soundproofing Membranes

New-generation soundproofing membranes combine high density with elasticity. Not just a film. Viscoelastic membranes based on mineral-polymer composites demonstrate an airborne noise insulation index of up to 65 dB at a thickness of just 2-4 mm — effectively blocking sound waves due to high mass and damping properties.

Acoustic membranes are produced using advanced soundproofing material technologies. Prices range from $18 to $68 per square meter, depending on technical specifications and manufacturer brand.

A comparative analysis of leading soundproofing membranes on the 2025 market is presented in the following table:

| Membrane Type | Thickness, mm | Density, kg/m² | Rw, dB | Effective Frequencies, Hz | Price, $/m² |

|---|---|---|---|---|---|

| Texsound FT55 | 2.9 | 5.5 | 28 | 100-2000 | 25-30 |

| SoundGuard Membrane | 2.0 | 3.8 | 25 | 250-4000 | 18-22 |

| MLV Premium | 3.2 | 6.8 | 32 | 125-1600 | 35-42 |

| Nano-membrane Pro | 1.5 | 4.2 | 30 | 500-8000 | 55-68 |

The data shows a direct correlation between material thickness, density, and soundproofing effectiveness, helping to choose the optimal solution based on budget and performance requirements.

Composite Soundproofing Materials

Composite soundproofing materials combine the advantages of various technologies. Multilayer soundproofing systems include reflective, absorptive, and damping layers in a single structure — acting as multilevel protection against different types of noise.

Soundproofing sandwich panels consist of a rigid frame filled with sound-absorbing material and covered with sound-reflective shells. It’s known that such a structure functions as an acoustic filter (like a layered cake for sound) — processing different frequencies at corresponding layers.

New-generation acoustic panels integrate nanomaterials, smart elements, and traditional absorbers. In a project last season, a combined system of metamaterials and composite panels reduced office noise from 58 to 32 dB — an impressive result for such a complex acoustic environment.

An acoustics specialist notes: "Composite materials achieve a sound absorption coefficient of 0.85-0.95 across a wide frequency range. With proper design, they save up to 40% of space compared to traditional solutions."

Frameless Soundproofing: ZIPS Systems

Frameless soundproofing offers ready-made solutions for quick installation. ZIPS panels (Soundproofing Panel Systems) are mounted directly to the wall without a metal frame, eliminating sound bridges.

The system works simply. Vibration-isolating nodes prevent vibration transfer. The sound-absorbing layer absorbs sound energy, while the finishing cladding reflects residual sound waves.

ZIPS soundproofing panels provide an increase in sound insulation ΔRw up to 18 dB with a system thickness of 53-133 mm. Installation takes 1-2 days without wet processes. Cost ranges from $45-85 per m², depending on the modification.

Vibration Isolation Materials and Mounts

Vibration isolation materials prevent the transfer of structural noise through building components. Vibration-isolating mounts with spring or elastomeric elements isolate ceiling structures from floor slabs.

Vibration isolation materials prevent the transfer of structural noise through building components. Vibration-isolating mounts with spring or elastomeric elements isolate ceiling structures from floor slabs.

Modern vibration isolation technologies include four main categories of solutions:

- Spring vibration mounts with a natural frequency of 8-12 Hz

- Elastomeric fixings made from specialized rubbers

- Vibration-isolating mats under floor screed

- Damping tapes for sealing joints

Combined use of these technologies provides comprehensive protection against structural noise at all building levels. Properly designed vibration isolation reduces impact noise transmission by 15-25 dB.

A study showed: in buildings with vibration-isolated structures, residents complain about neighbor noise 60% less often. Investments in quality vibration isolation pay off with living comfort and property value.

Eco-Friendly Soundproofing Materials

Eco-friendly soundproofing materials are a priority in 2025. Natural fibers, recycled materials, and biodegradable composites provide effective soundproofing without harming health.

Natural solutions are surprisingly effective. Cork panels demonstrate a sound absorption coefficient of 0.65-0.85. Flax and hemp mats match mineral wool in acoustic performance.

Recycled polyester from plastic bottles is transformed into high-quality sound-absorbing panels. In my work with private clients, families with children often choose these materials — absolute safety with excellent acoustic properties.

Frequency Characteristics and Material Selection

The effectiveness of soundproofing materials heavily depends on sound frequency. The human ear perceives a range of 20-20,000 Hz, but the most problematic are mid-frequencies of 500-2000 Hz (human speech, TV).

Comparative effectiveness across frequency ranges is presented below:

| Material | 125 Hz (LF) | 500 Hz (MF) | 2000 Hz (HF) | Optimal Application |

|---|---|---|---|---|

| Mineral Wool | 0.15 | 0.85 | 0.95 | Speech, TV, radio |

| Acoustic Membranes | 0.65 | 0.75 | 0.45 | Bass, music |

| Metamaterials (low-frequency) | 0.90 | 0.70 | 0.40 | Transport, vibrations |

| Cork Panels | 0.25 | 0.75 | 0.85 | Offices, classrooms |

The data highlights the need for a combined approach: dense materials for low frequencies, porous ones for high frequencies.

Material Quantity Calculation Methodology

Accurate material calculations prevent overpaying or shortages during installation. The basic formula accounts for surface area, waste coefficient, and material specifics.

Main calculation formulas:

- Membranes: Area × 1.1 (10% for overlaps and trimming)

- Panels and Mats: Area × 1.15 (15% for size adjustments)

- Liquid Materials: Area × layer thickness × 1.05

- Fasteners: 6-8 units/m² for panels, 12-16 units/m² for membranes

Example calculation for a 20 m² room: walls 45 m², ceiling 20 m². Membrane: 65 × 1.1 = 71.5 m². Fasteners: 65 × 14 = 910 units. Sealant: 18 m perimeter = 2 tubes of 310 ml.

Complex room geometry can increase waste by 20-25%.

Soundproofing Installation Conditions and Seasonal Features

Soundproofing quality directly depends on installation conditions. Temperature and humidity restrictions are critical for system durability.

Soundproofing quality directly depends on installation conditions. Temperature and humidity restrictions are critical for system durability.

Optimal installation conditions: temperature +5°C to +25°C, humidity 40-60%, no drafts. Polymer membranes lose elasticity below 0°C, and adhesives fail to set above 80% humidity.

Seasonal recommendations: spring-summer is ideal for all work, fall suits indoor tasks, and winter requires pre-heating the space and using quick-drying compounds.

In my work with private clients, winter installations extend timelines by 30-40% due to temperature compliance needs.

Fire-Resistant Soundproofing Materials

Fire-resistant soundproofing materials ensure safety without compromising acoustic properties. Non-combustible (NG) mineral wools and specialized composites withstand temperatures up to 1000°C.

Modern solutions combine fire safety with high efficiency. Basalt sound-absorbing panels are non-flammable and emit no toxic gases. Silicate panels with microporous structures achieve a KM0 fire hazard class.

Thus, selecting fire-resistant materials is critical for public buildings with stringent fire safety requirements.

Quality Soundproofing Checklist

Checking installation quality helps avoid costly reworks. Key control criteria are accessible for self-assessment.

Mandatory checkpoints:

- Joint Sealing: No gaps over 1 mm, high-quality sealing of all connections

- Mounting Without Sound Bridges: Vibration-isolating pads under all frame elements

- Membrane Integrity: No punctures, proper 50-100 mm overlaps

- Material Adhesion: Sound-absorbing mats with no air gaps

- Finish Quality: Smooth surface without cracks or deformations

Simple effectiveness test: play music at 70 dB in the insulated room; the level in the adjacent room should not exceed 40 dB for quality soundproofing.

Material Compatibility and Interaction

Proper compatibility of soundproofing materials is critical for system longevity. Chemically incompatible materials can degrade each other or lose properties.

Basic compatibility principles: polymer membranes are compatible with mineral mats, bituminous materials require protection from direct contact with polystyrene, and water-soluble adhesives are incompatible with moisture-absorbing materials.

Universally compatible materials: mineral wool, drywall, and acrylic-based acoustic sealants. They form the basis of most soundproofing systems.

Classification of Solutions by Price Categories

A structured approach to selecting soundproofing by budget categories helps make informed decisions.

| Category | Price, $/m² | Effectiveness ΔRw | Application | Material Examples |

|---|---|---|---|---|

| Economy | 25-45 | 8-12 dB | Residential rooms | Basic membranes, mineral wool |

| Standard | 45-85 | 12-18 dB | Apartments, offices | ZIPS, SoundGuard |

| Premium | 85-150 | 18-25 dB | Studios, cinemas | Composite panels |

| Innovations | 150-300 | 25+ dB | Labs, concert halls | Metamaterials, smart materials |

Category choice depends on effectiveness requirements, budget, and application specifics — from basic soundproofing to professional solutions.

Practical Guide: How to Choose Materials Correctly

Choosing soundproofing materials requires a systematic approach. The first step is an acoustic survey of the room with a sound level meter. Measure background noise and identify problematic frequencies.

A systematized approach to selecting soundproofing materials includes five mandatory steps:

- Noise Source Analysis: Airborne (voices, music), impact (footsteps, falling objects), structural (equipment vibrations)

- Target Level Determination: Based on international standards for the specific room type

- Required Effectiveness Calculation: Difference between current and target noise levels

- Technology Selection: Membranes for airborne noise, vibration isolation for structural noise

- Certificate Verification: Test protocols per ISO 10140, ASTM E90

Sequential execution of all steps ensures the selection of an optimal price-performance solution.

Expert recommendations based on analyzing hundreds of completed projects:

- For apartments up to 80 m², systems with ΔRw 12-15 dB are sufficient

- Use only E1-class eco-friendly materials in children’s rooms

- Studios require a comprehensive approach: walls + ceiling + floor

- Consider sound bridges in structures during old building renovations

These recommendations help avoid common mistakes and achieve maximum soundproofing effectiveness at optimal costs.

Common Soundproofing Mistakes and How to Avoid Them

Most soundproofing failures stem from improper design approaches. Analysis of 500+ projects revealed key mistakes and their solutions.

Mistake #1: Ignoring Sound Bridges

A metal frame passing through soundproofing reduces effectiveness by 50-70%. Solution: vibration-isolating pads at mounting points, use of damping materials.

Mistake #2: Wrong Material Choice

Foam is not soundproofing — it’s a sound absorber. Blocking noise requires dense, high-mass materials. In my work with private clients, I often encounter this misconception.

Mistake #3: Partial Soundproofing

Insulating only walls while ignoring ceilings and floors yields minimal results. Sound will find the weakest point in the structure.

Mistake #4: Skimping on Sealing

A 1 mm gap reduces wall soundproofing by 10-15 dB. All joints require high-quality acoustic sealant.

An acoustic engineer notes: "70% of soundproofing issues are resolved by proper joint sealing and eliminating sound bridges. Expensive materials won’t help if installation technology is violated."

Office case: 180 m² open-space with complaints about distracting conversations. Installed 1.6 m high acoustic partitions with an NRC coefficient of 0.85. Investment $4200, productivity increased by 18%, recouping costs in 8 months.

Effectiveness and ROI Calculation for Soundproofing

Soundproofing investments pay off in multiple ways. A 2024 study showed: quality soundproofing increases property value by 8-15%.

Multilevel analysis of soundproofing economic benefits includes:

- Property Value Increase: $5000-12000 with $2000-4000 investments

- Productivity Boost: A 10 dB noise reduction increases productivity by 15%

- Health Savings: Preventing stress-related diseases from noise exposure

- Energy Efficiency: Soundproofing materials often have thermal insulation properties

The cumulative effect of these factors ensures soundproofing investment payback within 3-5 years.

Simple ROI formula: (Property value increase - Soundproofing costs) / Costs × 100%. Typical ROI is 150-300% over 5 years.

In a project last season, a $3500 investment in soundproofing a 65 m² apartment increased its value by $8200, per an independent appraiser’s assessment (increase driven by comprehensive renovation, with soundproofing as one factor).

Conclusion: Why Invest in Soundproofing Now

Technological soundproofing materials in 2025 offer unprecedented opportunities for creating acoustic comfort. Modern soundproofing materials based on nanotechnology, metamaterials, and smart materials achieve up to 94% effectiveness with minimal thickness.

The right choice depends on analyzing the specific situation. Expensive doesn’t always mean better. A comprehensive approach using various material types often delivers the best price-quality ratio.

The acoustic insulation market grows by 6.2% annually, technologies improve, and innovative solution prices decrease. Don’t miss the moment. Investments in quality soundproofing pay off with comfort, health, and property value in the medium term — like an investment in your own well-being.