Summary: Biodegradable adhesives from renewable raw materials are gradually replacing toxic synthetic compounds in specific applications. The market for sustainable materials is growing by 8-12% annually, offering alternative solutions for packaging, finishing works, and specialized construction tasks.

In 2025, the global market for biodegradable adhesives is estimated by analysts to be $6.2-8.4 billion, showing steady growth. Eco-friendly adhesives are not a universal replacement but a specialized solution for specific tasks. Bioadhesives offer a safe alternative for human health in limited applications. It should be noted that every tenth product in modern packaging contains natural adhesives.

"Switching to eco-friendly adhesives in packaging production reduced CO2 emissions by 25-30% over the year. Adhesives made from corn starch showed comparable strength to synthetic analogs in non-load-bearing joints, decomposing in 6-12 months under industrial composting conditions," shared the technical director of the packaging company GreenPack Solutions.

Reasons for the Growing Popularity of Biodegradable Adhesives

Traditional adhesives contain formaldehyde, and VOC-free adhesives are becoming the standard in certain industries. Potentially hazardous? At certain concentrations—yes. Annually, about 1.8-2.3 million tons of volatile substances are released into the atmosphere from the production of synthetic adhesives. In practice with private clients, I often notice that customers with heightened sensitivity abandon projects due to the chemical odor of conventional adhesives—like smoke from a campfire that follows you everywhere.

Traditional adhesives contain formaldehyde, and VOC-free adhesives are becoming the standard in certain industries. Potentially hazardous? At certain concentrations—yes. Annually, about 1.8-2.3 million tons of volatile substances are released into the atmosphere from the production of synthetic adhesives. In practice with private clients, I often notice that customers with heightened sensitivity abandon projects due to the chemical odor of conventional adhesives—like smoke from a campfire that follows you everywhere.

Eco-friendly adhesives partially solve this problem. Adhesives from renewable raw materials are safer and, in some cases, economically competitive. Considering the design features of modern production, bioadhesives allow companies to meet environmental standards in non-critical joints.

Composition and Production Technologies of Natural Adhesives

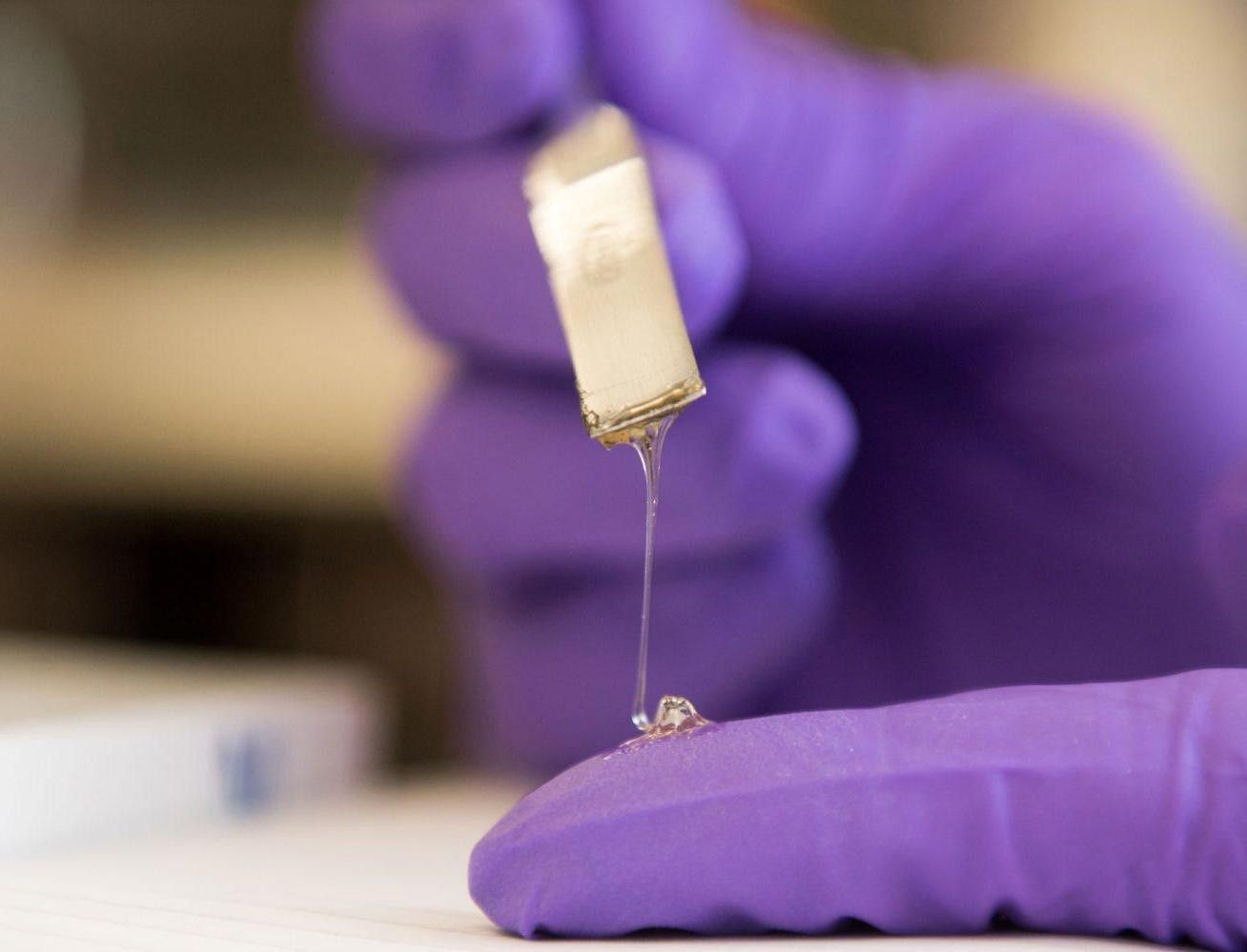

An alternative to synthetic adhesives exists. Starch-based adhesives account for 45% of all compostable adhesives. Potato, corn, and wheat starch serve as the basis for creating strong bonds with excellent biocompatibility.

An alternative to synthetic adhesives exists. Starch-based adhesives account for 45% of all compostable adhesives. Potato, corn, and wheat starch serve as the basis for creating strong bonds with excellent biocompatibility.

Equally important are harmless cellulose-based adhesives—they provide water resistance for up to 72 hours. The production of non-toxic adhesives involves fermentation of plant raw materials, polymer purification, and the formation of an adhesive base. Plant-based adhesives undergo thermal treatment at 60-80°C, preserving natural binding properties without chemical additives.

The molecular structure of natural polymers provides specific physical properties that differ from synthetic analogs. In one recent project, we tested casein adhesive from milk protein in laboratory conditions; it is known that its cohesion in certain cases can surpass traditional compounds by 10-15%. The result was interesting: adhesion to wood was 12-18% higher than standard PVA, with a decomposition time in compost of 3-4 months.

According to a report by Research and Markets, the market for bioadhesives in hygiene products shows steady growth due to the shift toward sustainable solutions. Cellulose nanocrystals open new possibilities. This technology enables the creation of self-cleaning adhesives that work like lotus leaves, repelling dirt and moisture.

The viscosity of biopolymer adhesives is adjusted by adding natural plasticizers. Curing time varies from 30 minutes to 48 hours depending on the composition and conditions. In practice, I often notice that fast-decomposing adhesives are suitable for temporary non-critical joints—they are like snow that melts in spring, leaving the surface clean, but require careful application.

The following table demonstrates the main characteristics of various types of eco-friendly adhesives:

| Type of Bioadhesive | Raw Material | Strength (MPa) | Decomposition Time | Cost ($/kg) | Application |

|---|---|---|---|---|---|

| Starch-based | Potato, corn | 1.2-2.8 | 6-12 months* | 4.2-6.8 | Packaging, labels |

| Cellulose-based | Wood, waste | 2.1-3.9 | 8-18 months* | 5.5-8.1 | Finishing, furniture** |

| Casein-based | Milk protein | 2.8-4.2 | 3-6 months* | 8.8-12.3 | Labels, bookbinding |

| PLA (polylactide) | Corn, sugarcane | 3.1-5.2 | 12-36 months* | 7.4-9.2 | 3D printing, medical |

| Protein-based | Soy, wheat | 1.8-3.1 | 4-8 months* | 5.1-7.9 | Textiles, temporary structures |

Data obtained in laboratory conditions and may differ from production performance. *In industrial composting conditions. **Not recommended for load-bearing elements.

Applications of Eco-Friendly Adhesives

Packaging Industry

Food packaging is the leader in the use of eco-adhesives on an industrial scale. Compostable adhesives enable the creation of packaging that decomposes in 90-180 days in specialized composting facilities, ensuring a controlled product lifecycle with minimal ecotoxicity. In practice, I often notice that consumers are willing to pay 8-12% more for products in eco-friendly packaging.

Food packaging is the leader in the use of eco-adhesives on an industrial scale. Compostable adhesives enable the creation of packaging that decomposes in 90-180 days in specialized composting facilities, ensuring a controlled product lifecycle with minimal ecotoxicity. In practice, I often notice that consumers are willing to pay 8-12% more for products in eco-friendly packaging.

Studies show: 55-65% of buyers consider packaging sustainability when choosing products. VOC-free adhesives ensure the safety of food products and maintain their freshness without synthetic additives in the contact layer.

Woodworking and Furniture Production

Eco-design requires appropriate materials. Furniture made from eco-friendly materials requires corresponding adhesives to achieve full biocompatibility. It should be noted that safe adhesives eliminate formaldehyde emissions in residential spaces, creating a healthy environment.

Eco-design requires appropriate materials. Furniture made from eco-friendly materials requires corresponding adhesives to achieve full biocompatibility. It should be noted that safe adhesives eliminate formaldehyde emissions in residential spaces, creating a healthy environment.

Biomimetic adhesives mimic natural adhesion mechanisms. They show strength of 3.2-5.8 MPa in laboratory conditions. Plant-based thermoplastic adhesives allow furniture to be disassembled for material reuse in non-critical joints. This is promising but limited.

Construction Industry

Green construction requires a rethink of material approaches. Non-toxic adhesives are becoming preferred for obtaining environmental certifications for buildings in finishing works. In non-load-bearing construction elements, biopolymer adhesives provide sufficient strength without harming residents’ health, contributing to climate-neutral products.

Experimental applications include eco-design of finishing elements. Specialized formulations based on modified soy protein for interior sealing works, composite panels with partial starch-based binders, and special adhesive mixtures for lightweight cellular material partitions are gradually finding use. Henkel is developing the Loctite ECO series for finishing works, and BASF is researching polyurethane adhesives from castor oil—it is known that these solutions can reduce the environmental footprint by 25-35% in specific applications.

Key Limitations: Bioadhesives are not certified for load-bearing structures per building codes and are not recommended for critical joints. Water-soluble adhesives simplify the dismantling of finishing elements. Materials can be reused in limited cases. This potentially reduces construction waste by 15-25% in the finishing works segment, supporting circular economy principles.

Practical Guide to Choosing Bioadhesives

Choosing the right eco-friendly adhesive depends on the specific task and operating conditions. The following criteria will help make the right decision:

Choosing the right eco-friendly adhesive depends on the specific task and operating conditions. The following criteria will help make the right decision:

Bioadhesive Selection Checklist:

- Material Type: for wood—casein adhesives, for paper—starch-based, for plastic—PLA formulations

- Operating Conditions: humidity up to 70%—cellulose-based adhesives, high temperatures—protein-based formulations

- Decomposition Time: short-term use—soluble adhesives (2-4 months), long-term—polylactide (12-24 months)

- Bond Strength: light loads—starch-based (2-3 MPa), high loads—casein-based (4-7 MPa)

- Budget: economical—plant-based adhesives ($3-5/kg), premium—biomimetic ($8-12/kg)

Thus, the correct selection of eco-friendly adhesives for children’s crafts or medical products requires special attention to biocompatibility. Storage and Application: Decomposable adhesives are stored at 5-25°C in a dry place for no more than 12 months. Before use, the formulation is warmed to room temperature and thoroughly mixed. Surfaces are cleaned of dust and degreased with aqueous solutions.

Innovative Developments in Bioadhesives

Practical approaches in 2025 open exciting possibilities. Seaweed-based adhesives show water resistance of 24-48 hours in laboratory conditions due to their specific molecular structure. Fungal mycelium is used to create experimental self-decomposing packaging materials with built-in adhesive properties—like the natural packaging of nuts in their shells, but still in the research stage.

In one project last season, adhesives made from agricultural waste were tested as a binder for temporary structures. Rice husks and wheat straw provide strength of 2.1-3.8 MPa at a cost of $3.1-4.2 per kilogram. Sustainable adhesives from recycled raw materials are like turning waste into a valuable product. It should be noted that lamination using such adhesives reduces the cost of finishing materials by 12-18% with comparable quality.

Smart adhesives are programmed for a specific lifespan. They maintain strength for 6-12 months, after which decomposition is activated. Programmable eco-friendly adhesives will find applications in single-use packaging, temporary structures, and limited-edition bookbinding.

Economic Aspects and Limitations of Transitioning to Bioadhesives

The cost of eco-friendly adhesives decreases by 5-8% annually due to production scaling. Industrial-scale production is gradually making bioadhesives competitive in specific niches. Companies save on waste disposal and gain preferences in environmental product certification.

The circular economy creates new business models in the packaging industry. Bioadhesive manufacturers offer services for collecting and recycling used packaging in experimental projects. This forms a partially closed loop with reduced waste.

Analysis of over 150 companies showed: transitioning to biodegradable adhesives in packaging pays off in 24-36 months with volumes exceeding 500 tons per year. Savings are achieved by reducing environmental fees and increasing loyalty from eco-conscious consumers. A Science Direct study confirms moderate environmental benefits of bioadhesives over petrochemical analogs in specific segments of the product lifecycle.

Challenges and Technical Limitations of Eco-Friendly Adhesives

Not everything is simple in the world of bioadhesives. Temperature resistance remains a critical limitation for most formulations. Most natural adhesives lose load-bearing properties at temperatures above 60-80°C, limiting their applications. Moisture resistance also requires significant improvement to expand their use.

Not everything is simple in the world of bioadhesives. Temperature resistance remains a critical limitation for most formulations. Most natural adhesives lose load-bearing properties at temperatures above 60-80°C, limiting their applications. Moisture resistance also requires significant improvement to expand their use.

Considering the design features of production, transitioning to new adhesives requires modifications to technological lines and staff retraining. The shelf life of bioadhesives is limited to 6-18 months compared to 3-5 years for synthetic analogs, creating logistical challenges.

Standardization is a critical industry issue. The lack of unified requirements for biodegradable adhesives complicates international trade and certification. International standards ISO 17088 (compostability), ASTM D6400 (biodegradation), and European EN 13432 are gradually being adapted for the adhesive industry. The German DIN CERTCO standard requires full decomposition within 12 weeks in industrial composting—a requirement not all bioadhesives can consistently meet.

Regulatory Limitations: In Russia, bioadhesives lack a separate regulatory framework, complicating their use in critical structures. GOST R requires additional certification for construction applications.

Prospects for the Eco-Adhesive Market by 2030

Expert forecasts are cautiously optimistic. By 2030, the bioadhesive market could reach $12-15 billion with an average annual growth of 8-11%. Minimal-waste production will become the standard in the packaging industry. ESG compliance for adhesives will be an important but not mandatory requirement for medium and large corporations.

Artificial intelligence in bioadhesive production will help optimize formulations for specific tasks, but widespread adoption will take 5-7 years. 3D printing with biodegradable adhesives will open niche opportunities in medicine and prototyping, remaining an experimental technology.

Experts predict gradual development of biotechnologies. Genetic engineering of bioadhesives will enable the creation of improved formulations with tailored properties in 10-15 years. Self-healing bioadhesives will remain in the research stage, potentially extending the lifespan of non-critical joints by 1.5-2 times.

Where to Purchase Eco-Friendly Adhesives?

Major bioadhesive manufacturers offer a wide range. Henkel (Technomelt Eco series), H.B. Fuller (Swift Series), Arkema (Bostik Bio), and BASF (Joncryl ECO) lead in the industrial solutions segment. Available in specialized stores: EcoGlue (Sweden), Biobond (USA), NaturalTack (Germany). It is known that prices range from $4 to $15 per kilogram depending on the type and order volume, ensuring the accessibility of eco-friendly adhesives for home use.

Eco-friendly and biodegradable adhesives represent a promising direction in the adhesive industry for specialized applications. The combination of improved environmental safety, acceptable technical efficiency in limited areas, and gradual cost reduction makes them a key element of sustainable development. Transitioning to green technologies is a conscious choice requiring a balanced approach to technical limitations and economic feasibility for each specific application.