Half-timbered houses capture the imagination. In recent years, Huf Haus homes and traditional half-timbered constructions have sparked genuine excitement among connoisseurs of authentic architecture, as if architectural masterpieces from Brothers Grimm fairy tales have found modern life. At one of the projects last season, I noticed how post-and-beam construction creates not only exceptional strength but also forms impressive aesthetics that remain relevant for centuries. Why are these technologies experiencing a second birth in the 21st century? In this article, we explore the features of each approach, their fascinating history, and key characteristics for creating truly unique living spaces.

From Medieval Masters to Modern Technologies: Evolution of Half-Timbering

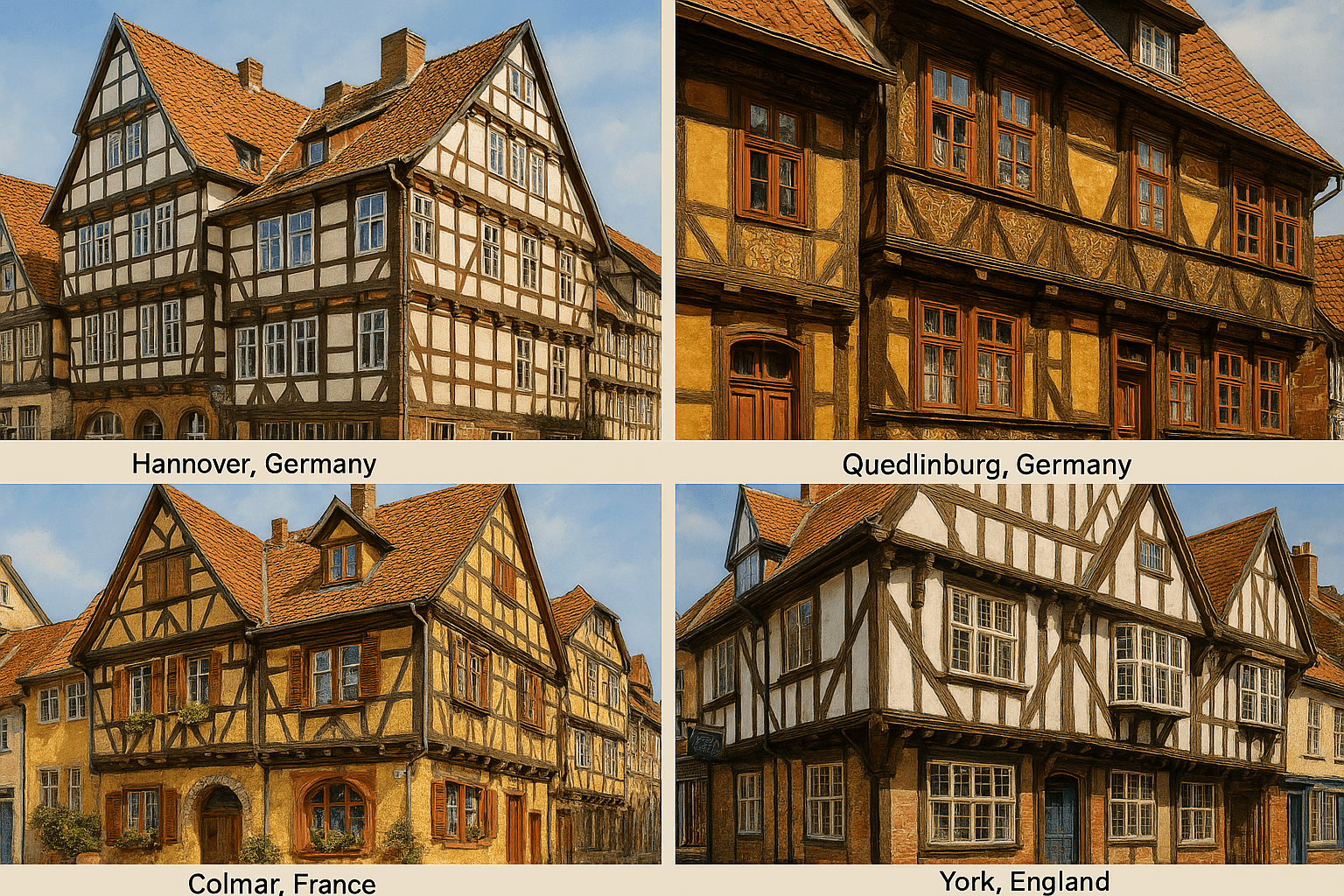

History begins in the 12th century. Half-timbered houses trace their roots to medieval Europe, where the heyday fell on the 15th-16th centuries, and the technology is experiencing a true revival since the end of the last century. It should be noted that traditional German half-timbered architecture amazes with its exposed wooden frame, where the beam construction is not just visible — it forms a unique visual rhythm both outside and inside the building.

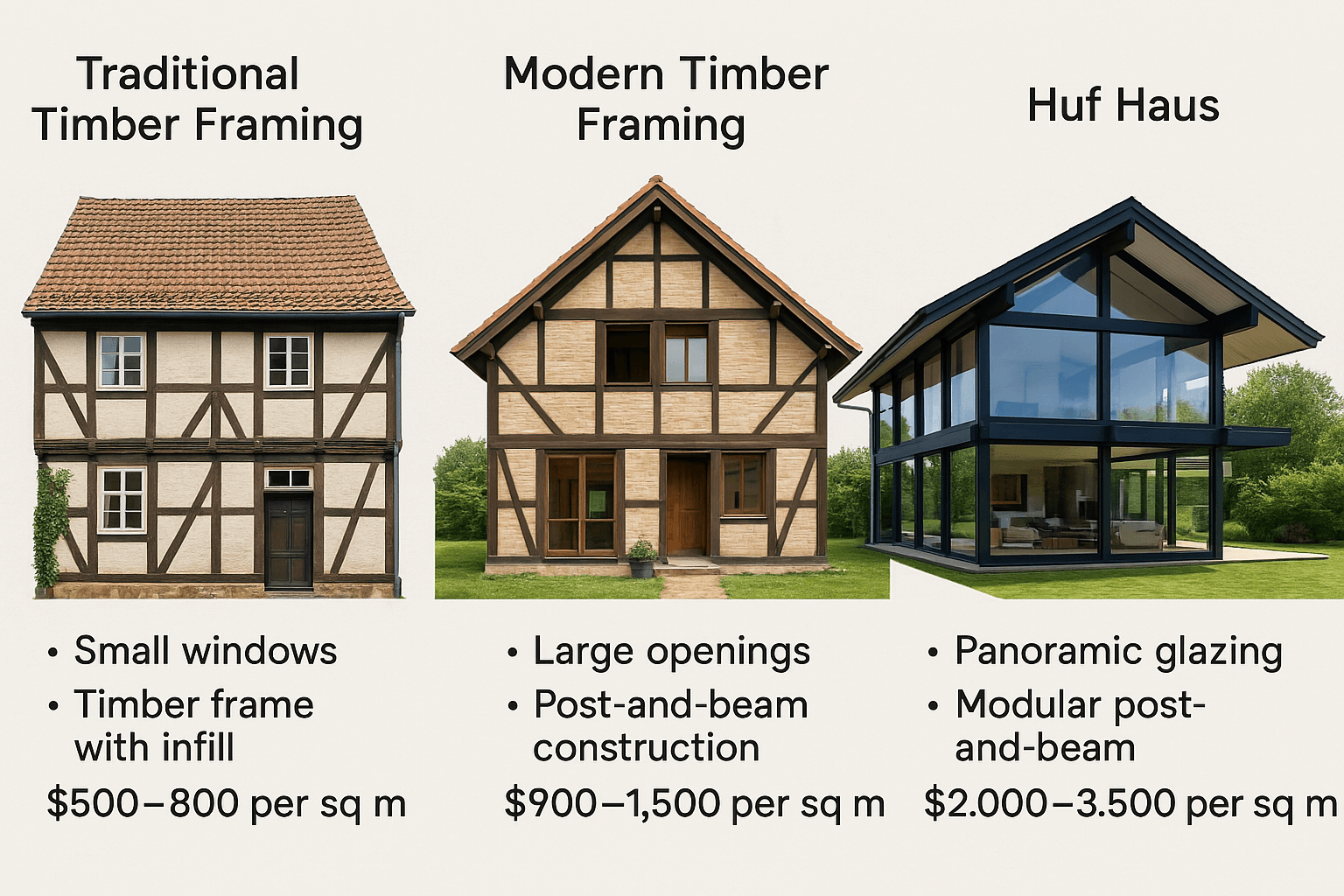

The system works simply and ingeniously at the same time. The features of half-timbered construction lie in a complex system of connecting vertical posts (studs), horizontal beams (plates), and diagonal braces. According to research by World Housing Encyclopedia, this technology was successfully used in various climatic zones from England to Switzerland, adapting to local conditions through the selection of appropriate infill materials.

"Half-timbering is not just a construction technology, it's a philosophy of human interaction with space. Exposed beams create rhythm and structure, reminding us of the connection with nature and traditions. At the same time, 21st-century half-timbered houses can be just as energy-efficient as any other high-tech building." — Peter Schmidt, architect specializing in frame houses

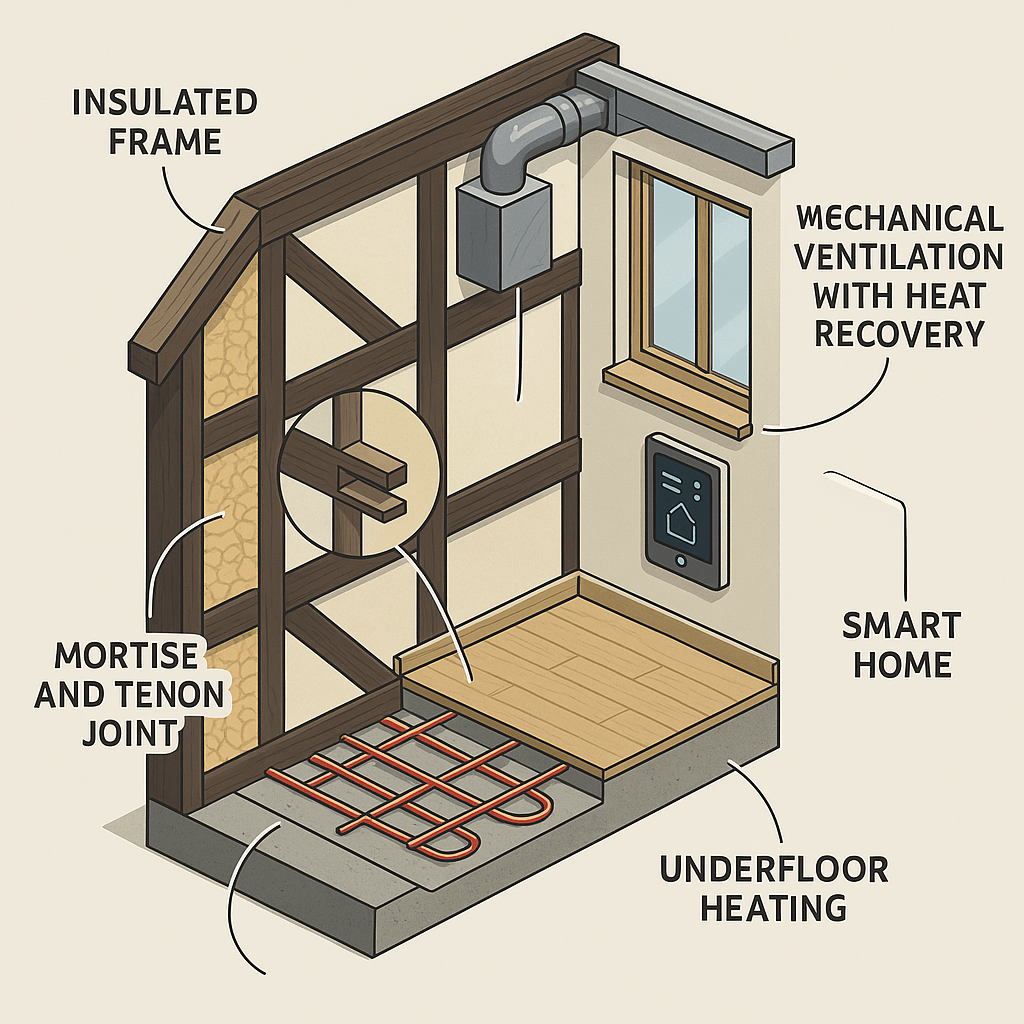

Materials have changed dramatically. In historic half-timbered houses, spaces between beams were traditionally filled with clay and adobe with straw, giving thermal conductivity of about 0.6-0.8 W/(m·K). Modern wooden houses of this type have transformed into high-tech constructions using SIP panels with thermal conductivity of 0.022-0.028 W/(m·K), mineral wool (0.035-0.045 W/(m·K)), or ecological wooden timber combined with advanced insulation materials.

Thus, structural connections of frame elements are performed using mortise-and-tenon technology with wooden dowels, which eliminates thermal bridges and increases the service life of the construction. This approach allows creating truly energy-efficient houses while preserving the captivating aesthetics and authentic character of traditional half-timbering.

Huf Haus: When Glass Meets Wood

The revolution began in Germany. Huf Haus construction technology embodies a rethinking of traditional frame houses, where impressive panoramic glazing (up to 70% of facade area) combines with modular construction with assembly precision up to 1 mm. In practice working with private clients, I often notice how the distinctive feature of these houses — post-and-beam frame from glued laminated timber with 12×12 cm cross-section — provides load-bearing capacity up to 450 kg/m², allowing creation of spans up to 8 meters without additional supports.

Glass units work as energy barriers. Triple-chamber systems are used with heat transfer coefficient of only 0.5-0.7 W/(m²·K), which exceeds ordinary glass units by two times. Engineering solutions of wooden frames with special reinforced connection nodes create houses with seismic resistance up to 9 points, despite their visual lightness.

| Parameter | Traditional Half-Timbering | Modern Half-Timbering | Huf Haus |

|---|---|---|---|

| Load-bearing structure | Wooden frame with post spacing 0.8-1.2 m | Post-and-beam construction with spacing 1.5-2.5 m | Modular frame with spans up to 8 m |

| Glazing | Small windows (10-15% of facade) | Enlarged openings (20-40% of facade) | Panoramic glazing (up to 70% of facade) |

| Energy efficiency | Low (U = 1.5-2.0 W/m²K) | High (U = 0.15-0.25 W/m²K) | Very high (U = 0.10-0.15 W/m²K) |

| Construction timeframe | 9-12 months | 3-6 months | 4-8 months (including manufacturing) |

| Cost per m² | 700 - 1000 $/m² | 1000 - 1600 $/m² | 2200 - 4000 $/m² |

| Payback period | Not applicable | 15-20 years (due to energy efficiency) | 25-30 years (considering premium nature) |

| Layout | Traditional division | Free planning (up to 80%) | Open space (up to 95%) |

| Climate adaptation | Moderate climate | Wide range (-30°C to +35°C) | Extreme climate (-40°C to +40°C) |

Numbers speak for themselves. The table clearly demonstrates the evolution of wooden frame construction from traditional half-timbering to technological Huf Haus solutions, where each technology has its advantages and application features depending on client preferences and construction conditions.

Where Ancient Traditions Meet High Technologies

Magic happens at the intersection of eras. Half-timbering and Huf Haus embody a unique architectural approach where centuries-old German building traditions transform into high-tech 21st-century solutions. It is known that instead of standard "boxes," these technologies create expressive houses with character, where each beam and connection carries not only structural but also aesthetic function.

Scientific research presents amazing facts. Living in houses with visible wooden structure reduces stress levels by 15–20% and improves sleep quality, while modern prefab construction offers a similar approach: rapid implementation, high energy efficiency, and adaptability to client requirements.

"In the era of ecological crisis, smart construction becomes a necessity, not luxury. Half-timbered and Huf Haus technologies demonstrate how to reduce housing carbon footprint by 30-40% without compromising comfort. These houses not only please the eye but also allow reducing heating costs by up to 70% compared to traditional technologies." — Andreas Weber, ecological construction expert, author of "Sustainable Architecture in Northern Regions" study

Engineers solve the puzzle of the century. When implementing half-timbered projects, builders masterfully solve the most complex task: preserving the authentic geometry of exposed beams while integrating the latest engineering systems inside the constructions. Taking into account structural features, underfloor heating, ventilation with heat recovery (efficiency up to 95%), smart home systems, and even built-in vacuum cleaners are hidden in the space between beams with minimum wall thickness of 30-35 cm, which is 40% thinner than comparable thermal conductivity brick constructions. Wastewater treatment technologies are also successfully integrated into the ecosystem of half-timbered houses, ensuring complete autonomy and minimal environmental impact.

How Modern Elements Transform Frame Houses

The market offers numerous solutions. Half-timbered construction companies offer houses with unique design and individual half-timbered planning, where the combination of glass and wood in construction creates expressive architectural solutions.

Details make the crucial difference. Stretch ceilings can harmoniously complement half-timbered house interiors, creating a stylish appearance while preserving exposed wooden beams. Multi-level constructions allow hiding engineering communications without violating the authenticity of half-timbered style, while integration techniques of various frame technologies in one project allow combining exposed half-timbered beams and panoramic glazing in Huf Haus style.

Real Story: When Dream Becomes Home

The Müller family sought a compromise. After studying various technologies, they settled on a hybrid variant — a half-timbered house with Huf Haus elements. "We wanted to get a warm, cozy house with exposed beams, but at the same time with abundant light and sense of space," says Alexander Müller. "Working with architects, we developed a project where traditional half-timbering neighbors with panoramic glazing."

The result exceeded expectations. The construction process took 7 months, and the house turned out not only energy-efficient but also unique in design. The cost of the half-timbered house was above market average, but quality and durability fully justify the investment.

What Makes Frame Technologies Special

Numbers are impressive. Frame construction technologies offer a unique combination of advantages but require a balanced approach to selection. Modern half-timbered houses amaze with their operational economy — heating costs amount to only $4-5 per m² per month during average Moscow winter, and their construction takes 60% less time compared to brick houses of similar area.

Investment attractiveness is obvious. Huf Haus houses represent a premium real estate segment where properties retain up to 95% of their value after 10 years of construction, and in some regions even demonstrate 5-8% annual growth. It should be considered that initial investments are impressive: basic Huf Haus cost in EU countries starts approximately from 2,000–2,500 euros per m² in basic configuration.

Swiss principles in action. Huf Haus architecture clearly shows line clarity, visual lightness, and functional minimalism. Many clients are attracted by fixed pricing that doesn't change during construction and guaranteed quality independent of "human factor." Huf Haus company particularly prides itself on its sustainable development approach, using only high-quality ecological materials and offering complete turnkey construction cycle.

"Choosing between half-timbering and Huf Haus, one should understand that you're investing not just in walls and roof, but in a certain life philosophy. These houses create special atmosphere and change your space perception. With proper design, such a house will serve generations, maintaining its architectural value and functionality." — Mikhail Krasnov, architect and designer

Individual Approach: From Idea to Implementation

Do you have an idea? If you plan to create a house combining Huf Haus glass architecture elements or traditional half-timbering, or a half-timbered house project is already developed, it's worth discussing with engineers and estimators for cost assessment and implementation feasibility.

Individual design opens unlimited possibilities. Your concept can become reality, combining the best features of these unique styles: half-timbered weather resistance and free planning in Huf Haus style frame houses.

Choice Between Heritage and Future

This is more than just construction. Half-timbered and Huf Haus technologies represent not just construction solutions — it's a life philosophy in harmony with nature and traditions. According to German Institute of Construction Technologies research, houses built with these technologies demonstrate exceptional time resistance and retain up to 75% of their original value after 50 years of operation.

When choosing, numerous factors should be considered. Not only budget (difference can be $15-20 thousand per m²), but also personal preferences, regional climate features, and long-term plans. Regardless of choice, your house will become not only reliable shelter but also an expressive architectural object that will inspire admiration from others and bring joy to owners for generations.

This is heritage for future generations. Not just housing — it's something to pass to children and grandchildren.