The chimney system is the most important element of a building with autonomous heating, on which not only comfort but also safety of living depends. Proper construction of a chimney requires adherence to building codes, consideration of the premises' features, and selection of appropriate materials. In 2025, about 65% of private homes in Ukraine still use heating systems that require installation of a quality chimney. Even a small error in the design or installation of the chimney structure can lead to serious consequences, including fire or carbon monoxide poisoning. The installation of a chimney, the price of which can vary from $300 to $1500 depending on the complexity of work and materials, is an investment in the safety of your home.

By the way, statistics show that improper installation of a chimney is the cause of approximately 40% of fires in private homes. It is especially important to consider all requirements for the chimney's passage through the roof and ensuring fire safety when installing the chimney system. In this article, we will look at the main features of erecting a chimney structure, stages of installation and types of materials, and also discuss how to calculate the optimal height and diameter of the chimney pipe.

Selecting Materials for Building a Chimney Structure

The right choice of material is the first and most important stage in chimney arrangement. The modern market offers many solutions, each with its advantages and disadvantages. Today, modular systems made of stainless steel are gaining popularity, but traditional brick chimneys remain relevant as well. For professional chimney masonry, it is important to choose only certified materials that will ensure not only efficiency but also the safety of the entire structure.

«The choice of material for a chimney should be based on three key factors: the type of heating appliance, the temperature of exhaust gases, and operating conditions. High-quality material will ensure not only safety but also the durability of the entire system», — notes Oleg Petrenko, a design engineer with 15 years of experience in the installation of chimney systems.

Brick Chimney: Traditions and Reliability

In modern construction, system chimneys are increasingly used, but brick flues still maintain their relevance. In my practice, there was a case of chimney installation in a house over 80 years old – and the old brick chimney was preserved in almost perfect condition. This is the best confirmation of the durability of such a structure. At the same time, it is extremely important to choose the right materials for the construction so that the chimney is reliable and properly performs its functions. Particularly popular is fireclay brick, which is distinguished by high heat resistance and stability of form even at extreme temperatures.

In modern construction, system chimneys are increasingly used, but brick flues still maintain their relevance. In my practice, there was a case of chimney installation in a house over 80 years old – and the old brick chimney was preserved in almost perfect condition. This is the best confirmation of the durability of such a structure. At the same time, it is extremely important to choose the right materials for the construction so that the chimney is reliable and properly performs its functions. Particularly popular is fireclay brick, which is distinguished by high heat resistance and stability of form even at extreme temperatures.

For the construction of a brick chimney, it is necessary to use quality stove bricks. They should not contain a large amount of marl and should have a smooth surface. But not just any brick is suitable for building a chimney structure! Avoid using hollow bricks for chimney construction – this creates a risk of combustion products penetrating inside the building and poses a serious health hazard.

The use of hollow bricks is especially critical in the upper part of the chimney above the roof. This area is subject to the greatest impact of wind, precipitation, and temperature fluctuations. Voids in the brick contribute to the rapid penetration of moisture into the structure, leading to its destruction and leaks in the roof.

Metal Chimneys and Modern Solutions

Today, metal chimney systems, especially sandwich chimneys, are becoming increasingly popular. They represent a structure of two pipes of different diameters with thermal insulation material between them. The main advantages of such systems are ease of installation and high efficiency. Last season, I encountered a project where the installation of a sandwich chimney took only one day – instead of a week that would have been required for brick masonry. According to the Chimney Safety Institute of America (CSIA), understanding the differences between prefabricated and brick chimneys is critically important for proper maintenance and safe operation of the entire system. In the market, you can find both single-walled and double-contour chimneys, with the choice depending on specific operating conditions.

Today, metal chimney systems, especially sandwich chimneys, are becoming increasingly popular. They represent a structure of two pipes of different diameters with thermal insulation material between them. The main advantages of such systems are ease of installation and high efficiency. Last season, I encountered a project where the installation of a sandwich chimney took only one day – instead of a week that would have been required for brick masonry. According to the Chimney Safety Institute of America (CSIA), understanding the differences between prefabricated and brick chimneys is critically important for proper maintenance and safe operation of the entire system. In the market, you can find both single-walled and double-contour chimneys, with the choice depending on specific operating conditions.

The coaxial chimney is another modern solution, especially suitable for gas boilers with a closed combustion chamber. The peculiarity of this system is that it combines the functions of removing combustion products and supplying air for combustion. This not only increases the efficiency of the heating equipment but also ensures operational safety. If you are choosing a chimney for a fireplace, pay attention to a system with increased heat resistance, as the temperature of exhaust gases can reach quite high values.

There are also ceramic chimneys – reliable and durable structures resistant to the effects of aggressive substances contained in combustion products. Such chimneys have a smooth inner surface, which contributes to better draft. But you need to be prepared that the cost of a ceramic chimney system is significantly higher than a metal one. When choosing, it is also worth considering the environmental friendliness of the chimney system, especially if the ecological aspect of house operation is important to you.

| Material | Service Life | Cost | Ease of Installation | Resistance to Condensate | Fire Safety |

|---|---|---|---|---|---|

| Solid Brick | 50+ years | Medium | Low | Medium | High |

| Stainless Steel (single-walled) | 10-15 years | Low | High | Medium | Medium |

| Sandwich Chimney | 15-25 years | Medium | High | High | High |

| Ceramic Modular | 30-40 years | High | Medium | Very High | Very High |

| Coaxial | 15-20 years | Medium | High | High | High |

This table will help you navigate the variety of materials for chimney systems and choose the optimal option taking into account the requirements for your heating system, budget, and maintenance preferences. When you decide to buy a chimney pipe, pay attention to these characteristics – they will determine the service life of the entire system. If you need consultation, it is better to order chimney installation from professionals who will help with the right choice.

Stages of Chimney System Installation

Proper installation of a chimney is a complex multi-step process requiring exact adherence to technology and the use of quality materials. You should not engage in its construction without appropriate experience and knowledge, as improper installation of the chimney pipe can lead to fire or carbon monoxide poisoning.

Design and Calculation of Chimney Parameters

Any chimney construction begins with design and precise calculation of its parameters. It is necessary to determine the optimal height of the chimney pipe and its diameter, considering the type of heating equipment, its power, and features of the building. The diameter of the chimney should correspond to the outlet pipe of the heating device or be slightly larger.

Any chimney construction begins with design and precise calculation of its parameters. It is necessary to determine the optimal height of the chimney pipe and its diameter, considering the type of heating equipment, its power, and features of the building. The diameter of the chimney should correspond to the outlet pipe of the heating device or be slightly larger.

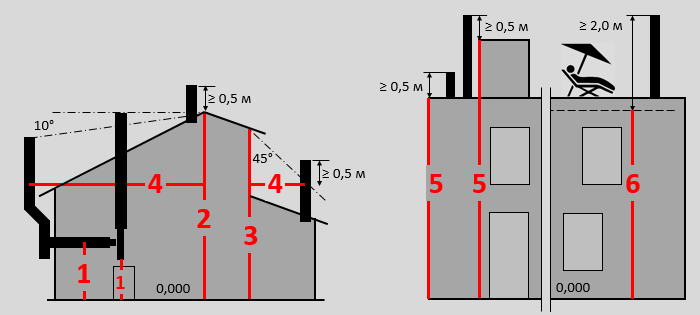

The height of the chimney is calculated taking into account the ridge of the roof. According to SNiP standards, if the chimney pipe is located at a distance of up to 1.5 m from the ridge, it should be at least 0.5 m higher than it. When located at a distance of 1.5 to 3 m from the ridge, the height of the pipe should be not lower than the ridge line. If the distance exceeds 3 m, the upper edge of the pipe should be above the line drawn from the ridge at an angle of 10° to the horizon.

«When designing a chimney, it is important to consider not only technical parameters but also the climatic features of the region. In areas with strong winds and abundant precipitation, it is necessary to provide additional protection for the chimney cap and ensure sufficient pipe height for stable draft», — emphasizes Andrey Kovalenko, chief architect of the design bureau «EcoConstructDesign».

Preparation of the Base and Foundation for the Chimney

The construction of a brick chimney requires adherence to certain stages and technologies. Initially, it is necessary to carefully prepare the base on which the chimney will be located. It should be strong and resistant to loads and deformations. A reinforced concrete slab is laid for the foundation.

To be honest, many homeowners underestimate the importance of a quality foundation for the chimney, believing that the main mass of the building is sufficient to support the structure. This is a serious mistake. An insufficiently strong foundation can lead to the subsidence of the chimney, formation of cracks, and destruction of the system.

Brick Masonry of the Chimney and Installation Features

After preparing the base, the stage of brick wall masonry follows. It is important to use a quality mortar and observe the bonding of bricks to ensure the strength and tightness of the structure. The wall thickness should be at least 120 mm (for solid brick), and in the upper part of the chimney above the roof, a thickening of the walls to 250-380 mm is recommended to increase their stability. Some craftsmen compare proper chimney masonry to art – as a conductor manages an orchestra, so a mason should feel each brick in the structure.

After preparing the base, the stage of brick wall masonry follows. It is important to use a quality mortar and observe the bonding of bricks to ensure the strength and tightness of the structure. The wall thickness should be at least 120 mm (for solid brick), and in the upper part of the chimney above the roof, a thickening of the walls to 250-380 mm is recommended to increase their stability. Some craftsmen compare proper chimney masonry to art – as a conductor manages an orchestra, so a mason should feel each brick in the structure.

As the masonry progresses, dividing walls between chimney channels are installed. To prevent the masonry from settling on these walls, metal ties are provided. All elements of the chimney structure must be securely fixed to exclude any sagging. When designing chimneys, it is important to consider not only technical parameters but also the aesthetics of the chimney, especially its visible part.

When installing metal chimneys, the installation process is significantly simplified. The system is assembled from bottom to top, elements are connected to each other and fixed with special clamps and cases to ensure maximum reliability. All joints must be sealed, for which special heat-resistant sealants are used. Do not economize on materials and components for chimneys – the service life of the entire system depends on their quality.

Passage Through Floors and Roofing

It is especially important to properly organize the passage of the chimney through floors and roofing. This is a critical point from a fire safety perspective. The distance between the outer walls of the chimney and structures made of combustible materials should be at least 130 mm for brick structures and 250 mm for ceramic ones. The separation of floors should be performed with special care and using non-combustible materials.

For waterproofing the places where the chimney passes through the roof, special rubber cuffs, mastics, and waterproofing compounds on cement or bitumen basis are used. It is important to ensure the sealing of the chimney to prevent leaks. The final stage is the arrangement of the chimney exit above the building roof and installation of a chimney cap (head) for protection from precipitation. In my experience, quality sealing of the passage through the roof is one of the key factors for the longevity of the entire system.

Safety Requirements When Building a Chimney

Safety is a key aspect in the design and installation of a chimney system. An improperly installed chimney can become a source of serious danger, including fire, carbon monoxide poisoning, or destruction of the building structure. Therefore, it is necessary to strictly observe all fire safety requirements and building codes.

Fire Prevention Measures and SNiP Standards for Chimneys

When building chimneys, it is necessary to strictly observe fire safety requirements. In particular, the distances from the chimney walls to wooden structures should be at least 50 cm. In the Kyiv office, I noticed that many clients are surprised by such a large safe distance – but this is a necessary precaution. According to a study by the U.S. National Bureau of Standards, the correct distance between the chimney and combustible materials is one of the key factors in preventing fires in residential homes.

The main safety requirements when installing a chimney structure:

- Use of only non-combustible materials for all structural elements

- Ensuring a minimum distance of at least 50 cm between the chimney and wooden structures

- Application of special separations when passing through floors and roofing

- Sealing of all connections to prevent leakage of flue gases

- Ensuring the stability of the structure to wind and temperature loads

- Protection from formation and accumulation of condensate

- Ensuring free access for maintenance and cleaning of the chimney

The story of one family from the Ivano-Frankivsk region became an instructive example of the importance of observing all safety standards when installing a chimney. In 2022, Vasily and Oksana decided to replace the old stove in their house with a modern fireplace. The contractor they hired offered to save money by using a simplified scheme for the chimney passage through wooden floors. Two months after the completion of the work, a fire occurred – the overheated part of the chimney ignited the wooden structures. Fortunately, the owners discovered the beginning of the fire in time and called rescuers. After this incident, they completely rebuilt the chimney system according to all regulations, hiring certified specialists. "We realized that saving on safety can cost too much," admits Vasily. Now the couple consults neighbors planning similar work, insisting on strict adherence to all safety requirements.

Ensuring Chimney Draft and Preventing Condensate Formation

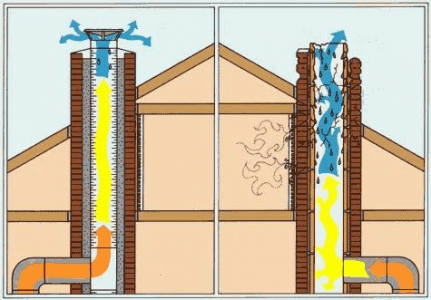

For effective chimney operation, it is necessary to ensure proper draft. As practice shows, insufficient draft is one of the most common problems with chimney systems. The draft is influenced by the height of the chimney (minimum 5 m from the grate), pipe diameter, insulation, and temperature of exhaust gases. True professionals always consider the aerodynamics of draft when designing a chimney system. It is more complex. But necessary.

For effective chimney operation, it is necessary to ensure proper draft. As practice shows, insufficient draft is one of the most common problems with chimney systems. The draft is influenced by the height of the chimney (minimum 5 m from the grate), pipe diameter, insulation, and temperature of exhaust gases. True professionals always consider the aerodynamics of draft when designing a chimney system. It is more complex. But necessary.

Another important aspect is the prevention of condensate formation. Condensate in the chimney not only reduces the efficiency of the system but also contributes to the destruction of the structure, especially if it is made of brick. To prevent condensate formation, it is important to ensure good thermal insulation of the chimney and correctly select the pipe diameter. In some cases, the installation of a chimney liner may be required – a special element designed to protect the inner surface of the chimney from the aggressive effects of condensate.

Care and Maintenance of the Chimney Structure

Regular maintenance of the chimney is the key to its long and safe operation. Even the highest quality chimney requires periodic care and preventive inspections. This will allow identifying and eliminating possible problems before they become serious.

Regular maintenance of the chimney is the key to its long and safe operation. Even the highest quality chimney requires periodic care and preventive inspections. This will allow identifying and eliminating possible problems before they become serious.

The main rules for maintaining a chimney system:

- Regular cleaning – at least once a year before the start of the heating season, and for chimneys from stoves and fireplaces using solid fuel – 2-3 times a year.

- Integrity check – inspection of inner and outer surfaces of the chimney for cracks, collapses, and other damages.

- Removal of soot and condensate – timely cleaning of sediment chambers from accumulated soot and condensate.

- Monitoring the condition of connections – checking the tightness of all joints and connections.

- Special attention to the upper part – checking the condition of the cap and the section of the chimney above the roof, most exposed to atmospheric influence.

- Full technical inspection – at least once every few years with measuring the thickness of walls and checking insulation.

- Timely repair – immediate elimination of even minor damages to prevent more serious problems.

When designing a chimney system, it is also important to consider the possibility of its maintenance and cleaning. It is not without reason that all building codes provide for the presence of special inspection openings – they are necessary for regular checking of the chimney condition and removal of soot. If you are looking for chimney installation services or a turnkey chimney, pay attention to companies that provide a guarantee for chimney installation and subsequent maintenance – this is an indicator of a responsible approach to work.

As we can see, the construction of a chimney structure is a complex and responsible process that requires a professional approach and adherence to all building codes and regulations. A properly designed and installed chimney will not only ensure the effective operation of heating equipment but also guarantee the safety of your home for many years.

For more detailed information on the requirements for the installation of chimney systems, we recommend referring to specialized literature or consulting with professional builders and engineers. When choosing materials and components for the chimney, prefer products from proven manufacturers and demand quality certificates. In matters of safety, economy is inappropriate – it's like building a house on sand instead of a solid foundation.