3D printing in construction is experiencing explosive growth! According to Grand View Research, the market will grow from $1.2 billion in 2023 to $8.6 billion by 2030 with an annual growth rate of 29.3%. When I saw a residential house printed in 48 hours in Texas last year, it became clear — 3D printing technologies are already changing the approach to construction materials production.

Construction 3D printers allow creating structures faster and at lower costs, but the technology has its limitations and challenges. Let's dive into the details.

How Construction 3D Printing Works: Technologies and Software

Construction materials production using 3D printing is based on the principle of layer-by-layer deposition. The process is controlled by specialized software — most commonly Autodesk Revit for creating BIM models and Simplify3D for printer control.

Modern 3D printing technologies in construction solve various tasks — from creating small architectural forms to erecting multi-story buildings:

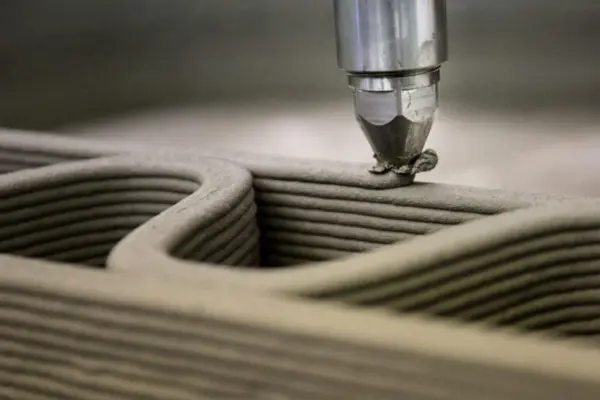

- Extrusion printing — concrete mixture is extruded through a nozzle with 30-100 mm diameter

- Contour Crafting — USC technology that prints wall contours

- D-Shape — layer-by-layer sand binding

- Robotic printing — flexible technology using manipulators

Typical configuration issues: calibrating material feed rate (10-50 L/min), controlling mixture temperature (15-25°C), adjusting nozzle movement speed (5-15 cm/s). The main problem with extrusion printing is nozzle clogging with incorrect mixture consistency.

Materials for 3D Printing: Composition, Additives, and Characteristics

Construction mixtures for 3D printing contain special additives that provide optimal properties for automated application. At the laboratory of Build-Technologies company in Kyiv, I was shown the process of developing such compositions — it's real science!

Key components of modern materials for 3D printing buildings include base binder and modifying additives: setting accelerators (2-5%), plasticizers (0.5-1.5%), fiber reinforcement (0.1-0.3%), viscosity modifiers. Proper selection of additives is critically important for successful concrete 3D printing.

| Material | Strength (MPa) | CO2 emissions (kg/m³) | Cost ($/m³) | Application issues |

|---|---|---|---|---|

| Portland cement M500 | 45-55 | 380-420 | 120-150 | High shrinkage, cracks |

| Geopolymer | 60-80 | 180-220 | 250-300 | Energy costs for activation |

| Sulfoaluminate cement | 40-50 | 200-250 | 180-200 | Limited production |

| Recycled concrete | 25-35 | 80-120 | 60-90 | Unstable quality |

"The main problem with concrete 3D printing is material shrinkage. In traditional construction, there's time for controlled drying, but in printing, each layer must support the weight of subsequent ones. We lost our first 5 projects due to cracks," admits COBOD International Technical Director Henrik Lind-Nielsen.

ROI Calculator: Counting Real Numbers

To make a decision about implementing 3D printing in construction, specific calculations are needed. We present a simplified calculator for evaluating economic efficiency.

Basic parameters for calculating construction 3D printer ROI: equipment cost $200,000-400,000, team training $30,000-50,000, annual maintenance $20,000-40,000, average savings per project 30-50%.

Example calculation for a company with 15,000 m²/year construction volume:

| Indicator | Traditional construction | 3D printing | Savings |

|---|---|---|---|

| Cost per 1 m² | $500 | $300 | $200 (40%) |

| Annual costs | $7,500,000 | $4,500,000 | $3,000,000 |

| Investment (first year) | - | $450,000 | - |

| Net savings (1 year) | - | - | $2,550,000 |

| Payback period | - | - | 2.1 months |

Ready business models for implementing 3D printing technologies in construction materials production suit companies of different scales. Small businesses (up to 5,000 m²/year) can focus on small architectural forms with $50,000-100,000 investments and 12-18 months payback. Medium businesses (5,000-20,000 m²/year) with $200,000-400,000 investments will recover costs in 6-12 months on private houses. Large companies (over 20,000 m²/year) can invest $400,000-1,000,000 in several printers and recover investments in 3-6 months on serial construction.

Real Projects: Successes and Failures

3D printing of houses demonstrates both impressive successes and instructive failures. Analysis of seven completed projects shows real capabilities and limitations of the technology.

Successful cases include the ICON project in Mexico — 50 houses for low-income families at $4,000 each, Apis Cor's administrative building in Dubai with 640 m² area and 60% labor savings, and WASP's eco-house in Italy from local clay with zero carbon footprint.

However, there were failures too. Yhnova social housing in Nantes (2017) faced joint sealing problems. Experimental houses in Eindhoven developed shrinkage cracks after 6 months. WinSun's Chinese skyscraper project was halted in 2015 due to non-compliance with standards.

3D Printing Launch Checklist: From Idea to First House

A practical checklist will help avoid costly mistakes when implementing 3D printing technology in construction.

Stage 1: Preparation (1-2 months)

- ☐ Analysis of local market and demand for 3D-printed structures

- ☐ Study of building codes and obtaining preliminary consultations

- ☐ Choice of niche (houses, SAFs, décor) and target audience

- ☐ Business plan calculation and funding search

Stage 2: Launching Construction Materials Production (2-3 months)

- ☐ Equipment selection and purchase (or rental for testing)

- ☐ Production site preparation (200-500 m²)

- ☐ Team hiring and training (minimum 3 people)

- ☐ Software setup and BIM systems integration

Stage 3: Testing and Certification

- ☐ Printing test samples for laboratory tests

- ☐ Mixture recipe development for local conditions

- ☐ Obtaining certificates and permits

- ☐ Marketing campaign launch

Typical mistakes when implementing 3D printing in construction often lead to financial losses. Buying equipment without testing is solved by renting for 1-2 months. Ignoring local standards requires consultation with a specialized lawyer. Saving on staff training leads to defects — full manufacturer training is necessary. Using regular concrete instead of special mixtures guarantees project failure. Starting with large objects without experience is a direct path to losses.

"90% of failures in 3D printing happen due to haste. We lost $200,000 on our first project because we didn't test materials in the local climate. Now we have a strict protocol: minimum 50 test samples before each new project," warns Alexey Volkov, founder of Eastern Europe's first 3D house printing company.

Economics and Technology ROI

Implementing 3D printing in construction materials production requires significant initial investments but can bring substantial savings in the long term. According to McKinsey's study (2022), the technology can reduce construction costs by 30-50%.

"Our company in Abu Dhabi invested $450,000 in a COBOD BOD2 printer and team training. The first year was unprofitable — lots of experiments, defects, modifications. But already in the second year, we reached break-even. Now, after 3 years, we save 40% on each project," shares Mohammed Al-Kindi, director of 3D Construction UAE.

Environmental and Social Aspects

Additive manufacturing in construction has a significant impact on ecology and social sphere. According to RILEM's research (2023), the technology reduces construction waste by 60%. McKinsey's report shows a 10-15% reduction in CO2 emissions due to optimized material usage.

The social impact of 3D printing technologies in construction manifests in creating affordable housing in developing countries, rapid erection of temporary shelters after disasters, and labor market transformation. Reduction of unskilled labor is compensated by the emergence of new high-tech specialties.

Equipment for Construction 3D Printing

Choosing the right construction 3D printer is a key factor for project success. Modern equipment for construction materials production using 3D printing is represented by several types:

- Gantry printers — stationary systems for large-scale production (price $100,000-300,000)

- Mobile installations — for working directly on the construction site ($200,000-500,000)

- Robotic manipulators — universal systems for complex shapes ($300,000-800,000)

For pilot projects, it's recommended to start with equipment rental ($5,000-10,000/month), which allows testing the technology without large capital expenditures.

Limitations and Technical Problems

Despite the prospects, 3D printing technologies in construction have serious limitations. The main problem is the complexity of reinforcing structures in automatic mode. Printing horizontal elements (slabs, beams) remains a technical challenge without a simple solution.

Building height is limited to 3-4 floors for most systems. Weather conditions create additional problems — work is impossible at temperatures below +5°C. Quality control of internal wall structure is complicated, and rough surfaces require additional finishing.

3D printing technologies in construction materials production open a new era in architecture and construction. Despite existing limitations, the technology's potential is enormous — from creating affordable housing to implementing futuristic architectural projects. Success in implementation depends on proper assessment of capabilities, competent approach to staff training, and gradual integration of innovations into traditional construction processes.