Choosing double-glazed windows for a balcony is a key decision for creating a comfortable space. Modern improved double-glazed units provide thermal resistance 2-3 times higher compared to single glazing, transforming the balcony into a full-fledged living space. According to Department of Energy research, quality windows can reduce heating and air conditioning costs by 10-25% depending on the climate zone. But how not to make a mistake when choosing balcony double-glazed windows among numerous offers?

Balcony glazing with double-glazed units is not just protection from bad weather. It's an investment in comfort. Properly selected warm double-glazed balcony units transform it into a cozy place for work or rest year-round, while the price of balcony double-glazed windows varies from $80 to $200 per square meter depending on technology.

"Modern double-chamber glazing units with low-emission coating reduce heat loss by 40-60% compared to traditional solutions" - notes thermal engineer Andrey Petrov.

Double-chamber glazing units for balcony: main types and selection

Single-chamber glazing units protect the balcony from precipitation and wind. They consist of two glass panes 4-6 mm thick, separated by an air chamber. Suitable for cold balcony glazing when only basic weather protection is needed.

Single-chamber glazing units protect the balcony from precipitation and wind. They consist of two glass panes 4-6 mm thick, separated by an air chamber. Suitable for cold balcony glazing when only basic weather protection is needed.

Double-chamber glazing units transform the balcony into a warm room. Three glass panes create two air chambers, providing serious thermal insulation for the balcony. It should be noted that such constructions are heavier and more expensive, but their service life is 20-25 years.

Triple-chamber glazing units are a premium solution. Four glass panes and three chambers. They provide maximum protection from cold down to -50°C, but have large weight and high cost.

What choice of balcony glazing units will be optimal for a specific case? The main selection criteria include the following parameters:

- Regional climatic conditions and balcony orientation by cardinal directions

- Planned room purpose - technical or living space

- Load-bearing capacity of the balcony slab and possible weight limitations

- Project budget and energy efficiency requirements

- Need for additional options: sound insulation, sun protection, security

These factors determine the technical solution and final cost of balcony glazing.

| Glazing unit type | Number of glass panes | Thermal resistance (m²°C/W) | Weight (kg/m²) | Price ($) | Application |

|---|---|---|---|---|---|

| Single-chamber | 2 | 0.32 | 20-25 | 80-110 | Cold glazing |

| Double-chamber | 3 | 0.47 | 30-35 | 120-160 | Warm glazing |

| Energy-saving single-chamber | 2 | 0.59 | 25-30 | 140-180 | Optimal solution |

| Multifunctional | 2-3 | 0.65 | 30-35 | 180-250 | South side |

The presented table will help navigate the characteristics of different types of glazing units and choose the optimal solution for specific tasks.

In practice, I often notice that balcony owners overpay for excessive characteristics. It's important to find a balance between efficiency and reasonable costs - like when choosing a smartphone, not everyone needs a professional-level camera. Loggia glazing units require a special approach due to the larger glazing area.

"When choosing glazing units, consider the balcony's purpose: for storage, single-chamber is sufficient, for living space - double-chamber with energy-saving coating" - advises architect Elena Sokolova.

Energy-saving glazing units: proven technologies

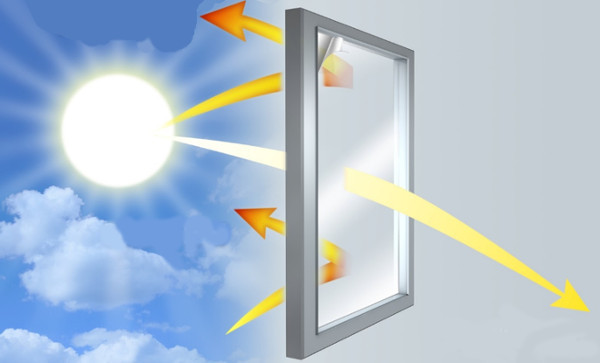

I-glass glazing unit contains invisible silver coating 10-15 nanometers thick. This coating reflects long-wave infrared radiation back into the room - like a selective mirror for thermal rays. In winter it retains heat, in summer it reflects excess solar energy, providing year-round comfort.

I-glass glazing unit contains invisible silver coating 10-15 nanometers thick. This coating reflects long-wave infrared radiation back into the room - like a selective mirror for thermal rays. In winter it retains heat, in summer it reflects excess solar energy, providing year-round comfort.

Low-emission glass blocks up to 90% of long-wave radiation while maintaining 70-80% light transmission. Thus, a single-chamber energy-saving glazing unit approaches the thermal characteristics of a regular double-chamber one in terms of thermal performance, but weighs 20-25% less.

Argon-filled glazing units are filled with inert gas instead of air. Argon has thermal conductivity 34% lower than air, which increases thermal resistance by 5-10% with proper filling. Krypton is more efficient but 10-12 times more expensive. Not always justified. But effective for premium projects.

In one of our recent projects, we used argon-filled glazing units for a north-facing 12th-floor balcony. The result exceeded expectations - the temperature difference inside the balcony and outside was 8-10°C at an outdoor temperature of -15°C. Department of Energy research confirms that energy-efficient windows can reduce heating costs by 10-25% depending on the climate zone.

In 2018, the Johnson family from British Warwick decided to update their balcony glazing with double-chamber glazing units with low-emission coating. During installation, they noticed strange laser markings that turned out to be EN 1279 quality marks. These markings confirmed a coating thickness of 700 microns and compliance with European safety standards. The balcony became comfortable even in cold winter months, which fully justified the investment.

Special types: tinted and multifunctional glazing units

Tinted glazing units protect from excessive sun and prying eyes. Glass with coating creates a mirror effect from outside while maintaining transparency from inside. Popular shades include bronze, silver, blue and green tones.

Tinted glazing units protect from excessive sun and prying eyes. Glass with coating creates a mirror effect from outside while maintaining transparency from inside. Popular shades include bronze, silver, blue and green tones.

Multifunctional glazing units are like a Swiss knife among window technologies. They combine energy saving and sun protection thanks to multilayer coating of 7-10 nanolayers of silver. It's known that such constructions can block up to 60% of solar energy in summer while maintaining 70% light transmission.

Impact-resistant glazing units are made from tempered glass or laminated glass (triplex). Impact strength is 5-7 times higher than regular glazing according to EN 12600. Suitable for first floors and panoramic balcony glazing where increased safety is required.

Sound insulation glazing units provide multilayer glass with PVB polymer film. The sound insulation index Rw is 32-38 dB for standard constructions - like transitioning from a busy street to a quiet park. Relevant for balconies facing transport arteries and industrial zones.

Considering the structural features of balconies, self-cleaning glazing units become a practical solution. Photocatalytic coating decomposes contamination under ultraviolet action. The technology works like natural rain - washes away dirt without human effort.

The service life of self-cleaning coating is 15-25 years according to manufacturer data. At one city center project, such glass stayed clean 2-3 times longer than regular ones. Window washing savings amounted to $150-200 annually for a 12-15 square meter balcony.

Choosing glazing units by climate zones: practical approach

Northern regions require enhanced balcony thermal insulation. Double-chamber energy-saving glazing units with argon are the minimum standard for comfort. At temperatures below -30°C, consider triple-chamber solutions with i-glass glazing unit technology.

Southern regions need protection from overheating more than insulation. Multifunctional glazing units block excess heat while maintaining natural room illumination. Tinted variants are effective against sun but reduce natural light by 15-25%.

Coastal zones face high humidity and aggressive salty air. Quality sealing and material corrosion resistance are important. Self-cleaning coatings are especially relevant here due to intensive contamination.

Mountain areas experience sharp temperature changes and strong winds year-round. Impact-resistant glazing units are mandatory for safety. It should be considered that increased wind load requires reinforced fastenings and thicker glass.

TOP-5 mistakes when choosing glazing units: avoiding problems

.png) Analysis of typical mistakes will help avoid costly miscalculations during glazing.

Analysis of typical mistakes will help avoid costly miscalculations during glazing.

Mistake #1: Saving on profile system with expensive glazing units. Cheap profile nullifies the advantages of expensive glazing. Like a weak link in a chain - the construction breaks at the thinnest point, and all investments lose meaning.

Mistake #2: Ignoring weight limitations of the balcony slab. Old balconies of P-44, 1-515 series are designed for 200 kg/m² load, modern glazing units with frame can weigh 35-45 kg/m². Engineering assessment of load-bearing capacity with safety margin calculation is mandatory.

Mistake #3: Overpaying for excessive characteristics without considering real conditions. Triple-chamber glazing units in southern regions are money down the drain. Select solutions for specific climatic conditions and room purpose.

Mistake #4: Poor quality installation to save budget. Saving $100-200 on installation can turn into thousands of dollars in problems in the future. Trust installation only to certified specialists with work experience.

Mistake #5: Lack of comprehensive approach to balcony insulation. Good glazing units without parapet and side wall insulation are ineffective. A balcony is a system requiring holistic engineering solution.

Avoiding these mistakes will save time, money and nerves when implementing the glazing project.

Smart glazing units: electrochromic technologies

Electrochromic glazing units are breakthrough technology in balcony glazing. They change transparency when 1-5 volt voltage is applied in 3-8 minutes. From completely transparent to dark blue state with 5-10% light transmission coefficient.

Electrochromic glazing units are breakthrough technology in balcony glazing. They change transparency when 1-5 volt voltage is applied in 3-8 minutes. From completely transparent to dark blue state with 5-10% light transmission coefficient.

The working principle is based on electrochemical reactions in multilayer WO3/Li+ coating. Applying small voltage starts the ion migration process and optical property changes. Energy consumption is minimal - 3-5 W per square meter only during switching.

Automatic light sensors regulate transparency without human participation according to a set algorithm. At illumination above 40,000 lux, glass automatically darkens, protecting from overheating. In cloudy weather it becomes maximally transparent.

It's known that smart glass blocks up to 99% of ultraviolet radiation and 50-70% of solar energy when fully darkened. This reduces air conditioning load by 15-25% in summer period.

In one of our Miami projects, we installed electrochromic glazing units on a south-facing 15th-floor balcony. Automatic darkening maintained comfortable temperature even at +38°C outdoor temperature and intensive solar radiation.

Smart glazing unit prices start from $600-900 per square meter including control system. High cost is partially compensated by air conditioning savings and increased comfort. Calculated service life is 20-25 years.

"Electrochromic glass is a promising direction in balcony glazing. They automatically adapt to lighting conditions, creating optimal microclimate without human intervention, but remain a niche product due to high cost" - believes smart materials technologist Dmitry Kozlov.

Plastic windows for balcony: profiles and components

Warm balcony glazing requires quality profile. 3-5 chamber PVC profiles provide reliable thermal insulation. Installation depth from 58 to 82 mm determines maximum glazing unit thickness and overall construction energy efficiency.

Warm balcony glazing requires quality profile. 3-5 chamber PVC profiles provide reliable thermal insulation. Installation depth from 58 to 82 mm determines maximum glazing unit thickness and overall construction energy efficiency.

Cold balcony glazing uses aluminum profiles. Light, strong, durable. But don't retain heat effectively. Suitable for technical balconies and regions with mild climate.

Glazing unit spacer bar is an important construction element, often underestimated by buyers. Aluminum bars are cheaper but create cold bridges around the perimeter. Plastic "warm" bars reduce heat loss by 10-15% and prevent condensation formation.

It's known that hardware quality directly affects window service life. European manufacturers guarantee 10,000-15,000 opening/closing cycles, which corresponds to 25-40 years of operation with moderate use (1-2 openings per day).

"Saving on hardware is false economy. Quality hardware serves 15-20 years, cheap requires replacement after 3-5 years" - warns technical expert Mikhail Volkov.

Installing glazing units on balcony: technology and nuances

Balcony glazing unit installation begins with assessing the construction's load-bearing capacity according to EN 1991-1-1 (Eurocode 1). Old balconies (series 1-510, 1-515) may not withstand additional load over 200 kg/m² from modern warm balcony glazing units. Engineering survey is a mandatory stage for safety assurance.

Balcony glazing unit installation begins with assessing the construction's load-bearing capacity according to EN 1991-1-1 (Eurocode 1). Old balconies (series 1-510, 1-515) may not withstand additional load over 200 kg/m² from modern warm balcony glazing units. Engineering survey is a mandatory stage for safety assurance.

Joint sealing prevents drafts and condensation according to EN 13830. Installation foam, sealants and vapor barrier tapes are used in a three-layer system. Poor quality installation nullifies the advantages of expensive glazing units - like a bad foundation destroys a strong house.

In practice working with private clients, I often encounter the desire to save on installation. This is wrong and dangerous. Quality installation is a guarantee of long service and safe operation.

Parapet and side wall insulation increases glazing efficiency by 20-30%. Without a comprehensive approach, even the best glazing units won't provide comfort. Scientific research shows the critical influence of insulation quality on building energy efficiency.

The main stages of quality installation include several critically important procedures:

- Dismantling old constructions and opening preparation with surface leveling

- Installing support elements and checking opening geometry

- Frame installation with technological gap compliance

- Three-layer joint sealing: vapor barrier, insulation, waterproofing

- Glazing unit installation and hardware adjustment

Violation of any of these stages can lead to serious operational problems.

Balcony glazing cost depends on many factors. Glazing area, glazing unit type, profile system, hardware quality - everything affects the final price. Basic glazing will cost $300-500 per linear meter at standard opening height of 1.5-1.8 m.

Energy-saving glazing units are 25-40% more expensive than regular ones. Multifunctional ones are 50-80% above base cost. But heating savings can pay back the difference in 7-12 years of operation depending on region and tariffs.

Expensive doesn't always mean quality. Sometimes you overpay for brand, not real characteristics. It's important to compare technical parameters, quality certificates and user reviews, not just prices in price lists.

Where to buy balcony glazing units with quality guarantee? It's better to order balcony glazing from proven companies with own production, warranty and service. Installation savings can turn into major repair expenses.

How to check glazing unit quality: expert methods

Quality glazing unit has clear manufacturer marking and production date according to EN 1279. Check tightness - there should be no dust, moisture or foreign inclusions inside chambers. Glass should be perfectly flat, without waves, distortions and optical defects per EN 572.

Quality glazing unit has clear manufacturer marking and production date according to EN 1279. Check tightness - there should be no dust, moisture or foreign inclusions inside chambers. Glass should be perfectly flat, without waves, distortions and optical defects per EN 572.

Energy-saving coating can be checked with a simple home method. Bring a lighter to the glass and look at the flame reflection. Reflection from i-glass will have a different color shade - usually reddish or purple instead of usual yellow-orange.

Spacer bar should be perfectly straight, without bends and deformations. Primary sealant (butyl) - without cracks, gaps and air bubbles. Secondary sealant (polysulfide or silicone) should evenly fill the joint. This is critically important for construction durability and preservation of insulation properties.

At one of last season's projects, we encountered defective glazing units - worker fingerprints and dust particles were visible inside. Such products were subject to immediate replacement, as tightness violation leads to fogging and property loss.

"When accepting work, be sure to check quality certificates and warranty obligations. Serious manufacturers provide 5-10 year warranty on glazing units" - recommends quality inspector Anna Fedorova.

Proper choice of balcony glazing units is an investment in comfort and energy savings. Consider balcony purpose, climatic conditions and budget. Modern technologies allow creating a cozy space for year-round use at reasonable costs.

Checklist: what to check when buying glazing units

Before purchasing glazing units, use this practical checklist to avoid mistakes:

Documents and certification:

- Manufacturer quality certificate

- Warranty obligations (minimum 5 years)

- Glazing unit marking with production date

Visual inspection:

- Absence of dust and moisture inside chambers

- Glass flatness without waves and distortions

- Sealant integrity around perimeter

- Correct energy-saving coating marking

Technical characteristics:

- Size compliance with project data

- Glazing unit thickness according to specification

- Chamber filling type (air/argon)

- Energy efficiency class

Installation conditions:

- Installation crew qualification

- Opening preparation quality

- Sealing technology compliance

- Installation work warranty

Following the checklist will help avoid 90% of problems when choosing and installing balcony glazing units.