Furniture hardware accounts for 15% to 25% of the cost of high-quality furniture in 2025, with the average cost of a kitchen set ranging from $3500-5000 in the USA and €2500-4000 in Europe. These are not just fastening components. Types of furniture hardware determine the functionality, durability, and visual perception of each piece of furniture, much like DNA defines the character of a living organism. In my work with private clients, I often notice that customers underestimate the impact of furniture components on the overall perception of a space.

Furniture hardware elements include hinges, handles, drawer slides, and lift mechanisms. The quality of furniture hardware creates a harmony between functionality and beauty. It’s worth noting that the furniture hardware market, according to European studies, continues to grow by 5.8-6.5% annually, reflecting the rising demand for premium solutions.

“Hardware is the DNA of furniture. It defines the character of the piece for decades to come. Skimping on these elements costs more in the long run.” — Mark Anderson, interior designer with 15 years of experience

Modern Furniture Hardware: Classification and Features

Choosing furniture hardware begins with understanding its classification. Concealed hardware ensures structural reliability while remaining invisible to the user. Visible hardware shapes the visual image of the furniture and becomes part of the design concept. Considering structural features, each type serves specific tasks within the overall furniture design concept.

Choosing furniture hardware begins with understanding its classification. Concealed hardware ensures structural reliability while remaining invisible to the user. Visible hardware shapes the visual image of the furniture and becomes part of the design concept. Considering structural features, each type serves specific tasks within the overall furniture design concept.

Can the role of invisible elements be underestimated? The main types of furniture hardware include hinges and pivots for cabinet doors, drawer slide systems, handles of various configurations, transformation mechanisms, and support elements. In one project last season, a client saved $200 on hardware but spent $600 on repairs within six months. Not the best calculation.

Furniture Hinges: The Technology of Reliability

Furniture hinges withstand between 50,000 and 200,000 cycles, depending on the class and manufacturer. This is a key indicator of furniture hardware durability according to DIN EN 15570 standards. In a recent project, we replaced standard hinges with soft-close systems — noise levels dropped significantly, and user comfort increased dramatically.

Furniture hinges withstand between 50,000 and 200,000 cycles, depending on the class and manufacturer. This is a key indicator of furniture hardware durability according to DIN EN 15570 standards. In a recent project, we replaced standard hinges with soft-close systems — noise levels dropped significantly, and user comfort increased dramatically.

Leading furniture hardware manufacturers offer advanced solutions for any task. Blum holds about 23% of the European market thanks to its CLIP-top technology and premium-class hardware design. Hettich offers Sensys systems with opening angles of 110-165 degrees, depending on the model. The functional hardware from these brands undergoes rigorous testing. Not always expensive. But always effective.

“Investments in quality hinges pay off within 2-3 years of use. Clients report a 40% increase in furniture usability comfort.” — European Furniture Manufacturers Association study, 2024

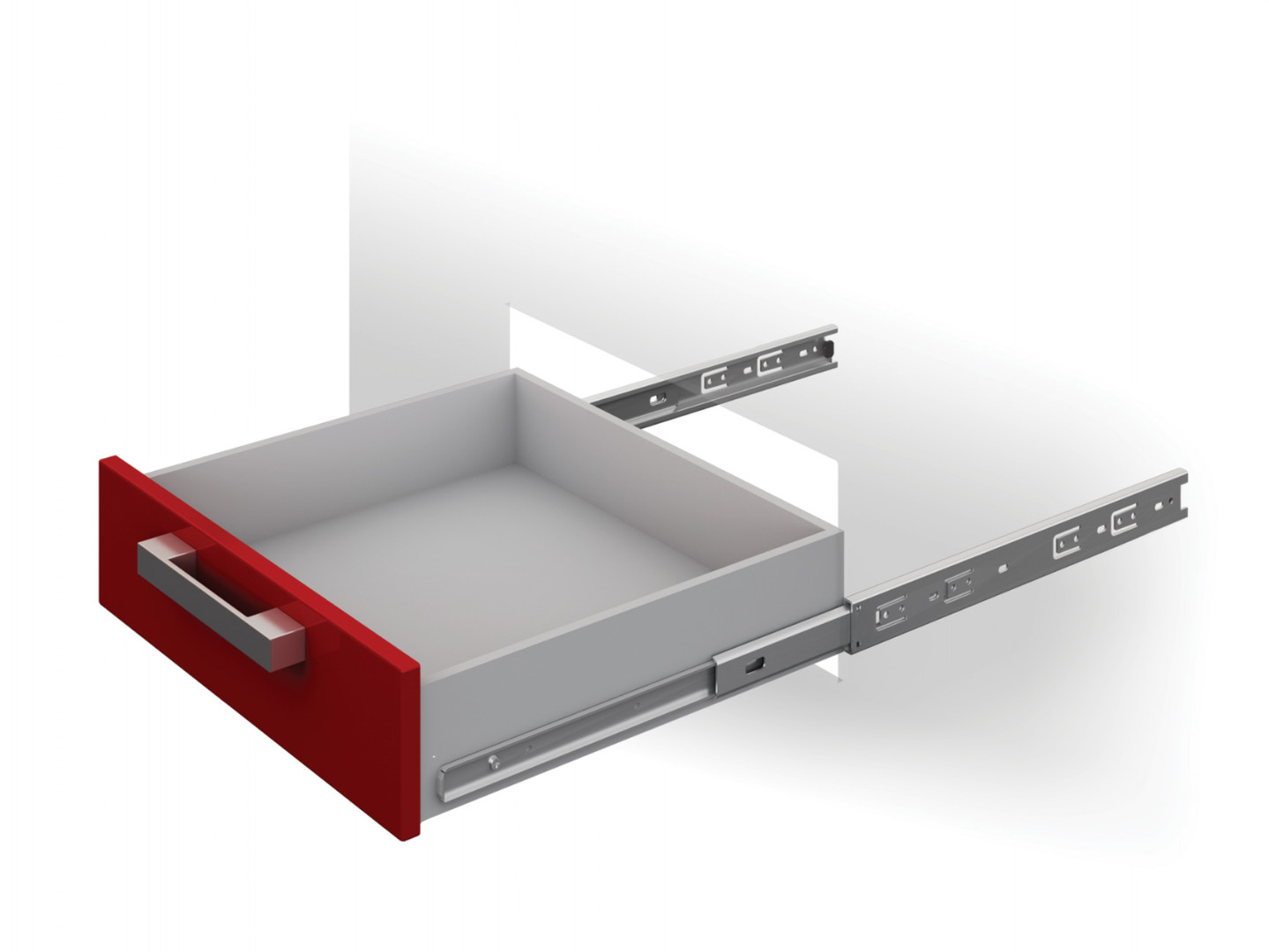

Drawer Slides: Smoothness in Every Motion

Drawer slide systems define daily usage comfort. Ball-bearing slides support loads from 25 to 35 kg, while reinforced telescopic models handle up to 60 kg while maintaining smooth operation. Telescopic systems provide 100% drawer extension. It’s known that the right choice of slides can extend furniture lifespan and significantly reduce wear on facades.

Drawer slide systems define daily usage comfort. Ball-bearing slides support loads from 25 to 35 kg, while reinforced telescopic models handle up to 60 kg while maintaining smooth operation. Telescopic systems provide 100% drawer extension. It’s known that the right choice of slides can extend furniture lifespan and significantly reduce wear on facades.

Lift mechanisms add elegance to kitchen cabinets. Push-to-open systems transform ordinary furniture into a smart home element. In practice, I often encounter situations where clients regret choosing budget slides after 2-3 years of use.

Materials and Technologies in Hardware Production

Choosing furniture hardware begins with understanding materials. Stainless steel ensures maximum durability. Brass adds a premium look. Zinc alloys offer an optimal balance of price and quality.

Innovative materials are transforming the industry:

| Material | Advantages | Average Price per Unit | Service Life |

|---|---|---|---|

| Stainless Steel | Corrosion resistance, strength | $18-30 | 20+ years |

| Brass | Aesthetics, antibacterial properties | $25-45 | 15-20 years |

| Zinc Alloy | Ease of processing, affordability | $10-18 | 12-15 years |

| Carbon Fiber Composites | Lightweight, wear resistance | $35-55 | 25+ years |

The table showcases the variety of modern materials and their characteristics, aiding in making an informed choice for a specific project.

“In 2023, our family upgraded an $8000 kitchen by replacing only the hardware for $1100. The result exceeded expectations: smooth drawer closing, silent operation, and a modern look. Neighbors thought we bought a new set. Savings amounted to about $5000, and the satisfaction from use skyrocketed.” — Sarah Johnson, housewife from Manchester

Aesthetics of Furniture Hardware: Trends and Styles 2025

Stylish furniture hardware follows the broader trends of contemporary interior design. Minimalism calls for concealed solutions and clean lines. Country style prefers natural materials and warm tones. High-tech opts for metal, glass, and automated technological solutions.

Stylish furniture hardware follows the broader trends of contemporary interior design. Minimalism calls for concealed solutions and clean lines. Country style prefers natural materials and warm tones. High-tech opts for metal, glass, and automated technological solutions.

Key trends for 2025, according to House Beautiful expert research, include concealed hardware for clean lines, matte finishes instead of glossy surfaces, integration with smart home systems, eco-friendly materials and coatings, and customization for individual needs. As a result, 45% of design projects incorporate personalized hardware created specifically for a given interior.

Functional Hardware for Different Zones

Kitchen furniture requires a special approach to component selection. Humidity and temperature fluctuations impose strict material requirements. In a recent project, we used hardware with antibacterial coating — clients noted significant improvements in kitchen hygiene and odor reduction.

Bathrooms demand maximum corrosion resistance for components. Bedrooms allow experimentation with decorative solutions and unconventional materials. Office furniture focuses on ergonomics, durability, and up to 50 daily usage cycles. It’s worth remembering: the right choice of furniture hardware depends on the room’s specifics and usage intensity.

“The right hardware transforms furniture from a mere object into a tool for improving quality of life. Soft closing saves nerves, reliability provides confidence, and beauty delights the eye daily.” — Anna Smirnova, interior architect

Quality of Furniture Hardware: Criteria for Professional Selection

Choosing quality hardware starts with a thorough analysis of needs. Usage frequency determines structural strength requirements. Interior style dictates aesthetic preferences and color schemes. Project budget influences the choice of materials, brands, and technological solutions.

Key criteria include the number of opening-closing cycles, maximum load capacity, alignment with interior style, ease of installation and maintenance, and the availability of a manufacturer’s warranty. In practice, I often notice that clients prioritize appearance over technical specifications. Thus, a professional approach to hardware selection ensures long-term satisfaction and cost savings.

Modern Furniture Hardware with Smart Technologies

Integration with smart technologies fundamentally changes perceptions of furniture. Electric drives enable control via smartphone or voice commands. Motion sensors activate lighting when someone approaches a cabinet. This turns ordinary furniture into a personal assistant responding to user needs.

Integration with smart technologies fundamentally changes perceptions of furniture. Electric drives enable control via smartphone or voice commands. Motion sensors activate lighting when someone approaches a cabinet. This turns ordinary furniture into a personal assistant responding to user needs.

30% of new hardware models in 2025 are equipped with electronic components and automation systems. The cost of such solutions drops by 15% annually due to mass production. Considering technological specifics, smart hardware is becoming a premium segment standard rather than an exotic option.

Durability of Furniture Hardware: Environmental Aspects

40% of manufacturers are transitioning to eco-friendly materials in 2025, following global sustainability trends. Recycled aluminum reduces the carbon footprint by 20% without compromising technical characteristics. Biodegradable coatings replace chemical alternatives in the eco-friendly product segment. Consumers are willing to pay 10-15% more for sustainable products. Detailed guidelines on designing environmentally sustainable furniture are provided in scientific studies.

Sustainability includes using recycled materials, reducing energy consumption in production, extending product lifespan, and enabling recycling after use. Eco-friendly hardware is becoming an industry standard. It’s known that leading companies invest up to 25% of their R&D budget in developing sustainable solutions.

“Sustainability is not just a trendy buzzword but an economic necessity. Eco-friendly hardware lasts longer, requires less maintenance, and creates a healthier home environment.” — Institute of Sustainable Design report, 2024

Step-by-Step Guide to Choosing Hardware

Choosing the right hardware requires a systematic approach. We present a buyer’s checklist based on the practical experience of professionals.

Buyer’s Checklist

- Determine the type of furniture and usage frequency

- Calculate the maximum load on components

- Select material based on operating conditions

- Match hardware style to interior design

- Verify compatibility of systems from different manufacturers

- Confirm availability of warranty and service support

Following this algorithm minimizes the risk of errors and ensures optimal results.

Hardware Installation and Maintenance

Quality installation determines hardware durability. Essential installation tools include a drill, wood drill bits, screwdrivers, and measuring instruments.

Quality installation determines hardware durability. Essential installation tools include a drill, wood drill bits, screwdrivers, and measuring instruments.

Common Installation Mistakes

- Inaccurate marking of hinge holes

- Exceeding recommended screw tightening torque

- Ignoring material thickness requirements

- Installing slides without checking parallelism

The preventive maintenance schedule includes lubricating mechanisms every 6 months and checking fastenings annually.

Hardware Budget Planning

Hardware costs account for 15-25% of the total furniture project budget, depending on the product class. For a 10 sq.m kitchen, a basic set costs $400-700, while a premium set ranges from $1000-1800.

| Brand | Price Segment | Best For | Warranty |

|---|---|---|---|

| Blum | Premium ($35-80) | Kitchens, frequent use | Lifetime |

| Hettich | Mid+ ($20-45) | Office furniture, cabinets | 10 years |

| Hafele | Mid ($15-30) | Universal use | 5 years |

| Boyard | Budget ($8-20) | Rarely used furniture | 2 years |

The table helps select the optimal price-quality ratio for specific tasks and project budgets.

Furniture hardware is an investment in interior comfort and durability. The right choice of furniture hardware components ensures a harmony of functionality and aesthetics for years to come. In an era of smart technologies and environmental consciousness, furniture hardware is becoming increasingly technological and environmentally responsible.

It’s worth remembering: skimping on quality hardware leads to additional costs in the future, based on the practical experience of professionals. High-quality furniture components from trusted manufacturers are the foundation of creating an interior that delights with functionality and beauty for years.