Water leaking through walls after rain? Drafts from under windows? Mold on panel joints? If you live in a panel building, these problems are all too familiar. Panel joint sealing isn't just a construction procedure—it's a real solution for comfortable living. Let's understand how to properly insulate panel joints and eliminate leaks through seams once and for all, while saving up to 30% on heating costs.

Types of Panel Buildings and Their Sealing Features

To properly order joint sealing services, it's important to understand your building's characteristics. Panel joint waterproofing technology directly depends on the building series and inter-panel connection specifications.

To properly order joint sealing services, it's important to understand your building's characteristics. Panel joint waterproofing technology directly depends on the building series and inter-panel connection specifications.

| Building Type/Series | Joint Features | Typical Problems | Recommended Sealing Materials |

|---|---|---|---|

| Khrushchev-era (1-335, K-7) | Narrow joints (10-20 mm), cement filling | Cracking, crumbling | Acrylic sealants, thin vilaterm |

| Brezhnev-era (P-44, P-3) | Medium joints (20-30 mm), bitumen mastic | Mastic deterioration, leaks | Polyurethane sealants, standard panel joint insulation |

| Modern (P-44T, KOPE) | Wide joints (30-50 mm), complex sealing | Settlement deformations | Hybrid sealants, multi-layer system with foam |

| Monolithic-panel | Expansion joints (40-60 mm) | Structural movement | Highly elastic materials, Oxyplast sealant, special profiles |

Proper identification of building type allows selection of optimal joint sealing services and avoids 70% of errors in panel building joint repair.

"In my 20 years in the construction industry, I've seen hundreds of improper sealing cases. The most common mistake is using the same approach for different building types. You can't apply the same technology in a Khrushchev-era building with narrow joints as in a modern panel building with expansion joints. Proper building type diagnosis saves up to 40% of the repair budget," notes Alexander Voronov, Chief Engineer at BuildTech Solutions.

Why Panel Joints Deteriorate: 7 Main Reasons

To effectively eliminate panel joint freezing and prevent heat loss through joints, it's essential to understand the causes of their deterioration. Here are the main factors affecting facade joint condition:

To effectively eliminate panel joint freezing and prevent heat loss through joints, it's essential to understand the causes of their deterioration. Here are the main factors affecting facade joint condition:

- Temperature deformations — panels expand and contract with temperature changes, creating stress in joints

- Building settlement — especially critical during the first 3-5 years after construction, requires special attention during initial joint sealing

- Vibration loads — from traffic, construction work, seismic activity

- Material aging — natural degradation of sealants and insulation

- Poor installation — technology violations during crack filling

- Chemical corrosion — exposure to acid rain and industrial emissions

- Mechanical damage — impacts, vibration from repair work

Statistics show that combining 2-3 factors accelerates inter-panel joint destruction by 5 times, making timely turnkey joint repair an economically justified solution.

Modern Sealing Methods: From Traditional to Innovative

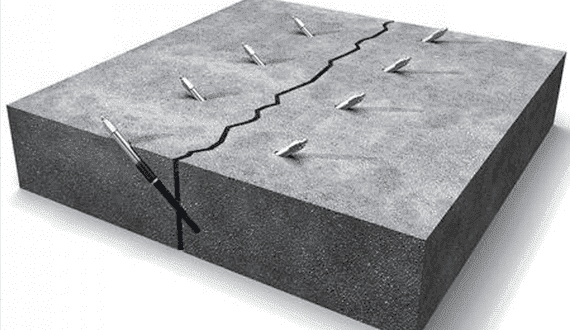

Injection Penetrating Joint Waterproofing — A Revolution in Repair

This technology, gaining popularity in Europe and the USA, restores seal integrity without opening the joint. Special compounds are pressure-injected into microcracks, polymerize, and create a waterproof barrier. Let's examine the key features of this method:

This technology, gaining popularity in Europe and the USA, restores seal integrity without opening the joint. Special compounds are pressure-injected into microcracks, polymerize, and create a waterproof barrier. Let's examine the key features of this method:

- Advantages: minimal intervention, work from inside premises, speed of execution

- Disadvantages: high cost of facade joint sealing ($80-120 per meter), requires special equipment

- Effectiveness: solves balcony joint leaks in 85% of cases without exterior work

- Materials: penetrating compounds like Penetron, crystalline waterproofing agents

Injection technology is especially effective for localized repairs and hard-to-reach areas where traditional methods can't be applied.

Comparison with European Standards for Moisture and Draft Protection

International quality standards define requirements for materials and technologies. Understanding these differences will help choose the right approach to inter-panel joint treatment and ensure building energy efficiency.

| Parameter | European Standard | American Standard | Typical CIS Practice |

|---|---|---|---|

| Minimum sealant elasticity for panel joints | 25% (class 25LM) | ±25% (Class 25) | Not regulated |

| Service life | 25 years (with warm joint technology) | 20 years minimum | 10-15 years |

| Environmental requirements | VOC < 40 g/L | VOC < 50 g/L | Partially regulated |

| Sealing cost | €50-80 per linear meter | $60-100 per linear meter | $15-60 per linear meter |

Compliance with international standards during major panel building repairs guarantees result durability and meets modern energy efficiency requirements.

Climate Considerations for Alpine Joint Sealing

Technology and material selection critically depends on climate zone. Proper consideration of local conditions when filling inter-panel joints—price per meter may vary, but saving on unsuitable materials will lead to cheap panel joint re-repair after 2-3 years.

Northern Regions (annual temperature range > 60°C)

In extreme temperature conditions, proper inter-panel joint insulation is especially important. Recommendations for cold climates include the following requirements:

- Mandatory use of highly elastic materials (elasticity > 400%)

- Increased insulation thickness (vilaterm or foamed polyethylene 40-50 mm)

- Use of frost-resistant sealants (operating down to -40°C)

- Additional wind load protection

- Use of "tight joint" technology with multi-layer insulation

Following these recommendations ensures reliable protection from freezing and drafts even in the harshest cold.

"In our residential complex in Minneapolis, winter temperatures drop to -35°C. After a failed experience with regular sealants that cracked after the first winter, we switched to 'warm joint' technology using special arctic materials. The result—7 years without a single leak and 32% reduction in heating costs," shares David Anderson, Property Manager at Nordic Properties.

Coastal Areas (high humidity, salt air)

Aggressive environments require a special approach to panel joint waterproofing. For coastal zones, the following measures are critical:

- Use of sealants with enhanced salt resistance

- Mandatory priming with anti-corrosion compounds

- More frequent maintenance (every 3-5 years)

- Application of biocidal additives against mold at joints

- Special mastics for joints with antiseptic properties

These measures prevent premature material deterioration and fungal development in humid climates.

Seismically Active Zones

Increased structural movement requires a special sealing approach. For seismically active regions, the following is necessary:

- Use of special deformation profiles

- Sealants with elasticity > 600%

- Reinforced joint armoring

- Frequent inspections after seismic activity

- Application of Isokom or Porilex sealants with enhanced elasticity

This approach ensures joint integrity even with significant building structure movement.

Prevention: How to Extend Joint Life and Prevent Leaks

Regular maintenance increases inter-panel connection service life by 2-3 times and prevents expensive major repairs. Proper facade joint care is an investment in your building's longevity.

Preventive Inspection Schedule

A systematic approach to joint condition checking helps identify problems early. The recommended schedule includes:

- Visual joint inspection in spring (after winter loads)

- Sealant elasticity check by pressing

- Search for cracks and peeling at panel junctions

- Photo documentation of problem areas

- Insulation condition check in accessible areas

Regular inspections allow timely detection and elimination of minor defects before they become serious problems.

Preventive Secondary Joint Sealing Work

Every 3-5 years, the following preventive measures are recommended:

Every 3-5 years, the following preventive measures are recommended:

- Joint cleaning from dirt with a soft brush

- Antiseptic treatment at first signs of mold

- Spot repair of minor damage with Penoflex sealant

- Renewal of top protective mastic layer

- Vilaterm condition check in exposed areas

These simple measures significantly extend sealing service life and save money on major repairs.

Seasonal Winter Preparation

Before the cold season, be sure to check joint condition and eliminate even minimal damage—in winter, small cracks turn into serious destruction due to water freezing. Timely inter-panel joint treatment saves significant heating costs.

"Prevention is 90% of success in fighting leaks. In our HOA, we introduced mandatory spring joint inspections. In 5 years of this practice, emergency repairs decreased from 12-15 to 1-2 per year. Savings on emergency work amounts to about $15,000 annually," says Elena Martynova, HOA Chair of "Sunny Quarter."

Modern Sealant Composition: What's Important to Know When Choosing

Understanding basic composition helps choose the right material for your conditions. Each sealant type has its application features for inter-panel joint waterproofing.

Sealant Classification by Chemical Composition

The modern market offers a wide selection of sealing materials. Main types include:

- Polyurethane sealants: base—polyurethane polymers, excellent concrete adhesion, ideal for warm joint technology

- Silicone sealants: base—polysiloxanes, excellent UV and water resistance, suitable for joint sealing in high-humidity areas

- Acrylic compounds: water dispersion of acrylic polymers, eco-friendly, suitable for interior work

- Hybrid MS-polymers: modified silanes, combination of best properties, optimal for industrial alpinism

- Bitumen mastics: petroleum bitumens with additives, budget option for temporary repair

Sealant type selection should be based on specific operating conditions and durability requirements.

Specialized Sealant Additives

Modern manufacturers improve sealant properties with special additives that expand their functionality:

- Fungicides — prevent mold development at joints

- UV stabilizers — protect from solar radiation damage

- Plasticizers — increase elasticity at low temperatures

- Thixotropic agents — prevent runoff from vertical surfaces

These additives significantly improve sealant performance characteristics and extend service life.

Recommendations for New Panel Building Residents: How to Avoid Problems

The first 3 years of a new building's life is a critical period for inter-panel joints. Proper actions during this period help avoid serious problems and the need to order joint sealing prematurely.

The first 3 years of a new building's life is a critical period for inter-panel joints. Proper actions during this period help avoid serious problems and the need to order joint sealing prematurely.

First Year — Active Settlement Period

During this period, major deformation and settlement of panel buildings occurs. Recommendations for the first year of operation:

- Don't rush with expensive finishing near joints

- Document all appearing defects

- Demand warranty repairs from the developer

- Conduct monthly photo documentation of problems

- Monitor for first signs of leaks through joints

Attention in the first year helps timely notice and eliminate problems under developer warranty.

"After buying an apartment in a new building, I immediately started photographing all joints and corners. After a year, the first cracks appeared. Thanks to photo documentation, I managed to get the developer to perform complete sealing under warranty. Neighbors who didn't document defects in time are now repairing joints at their own expense—about $2,000 per apartment," shares Mikhail Petrenko, apartment owner at "New Horizons" residential complex.

Second-Third Year — Stabilization

The period when it becomes clear whether serious inter-panel joint repair is needed. During this time, it's important to:

- Conduct comprehensive inspection of all joints

- If necessary, perform preventive sealing

- Install protective canopies over problem joints

- Consider applying warm joint technology to problem areas

Timely measures during the stabilization period prevent serious problems from developing in the future.

After Three Years

The building is considered stabilized. If problems persist, major joint repair using modern technologies is required. At this stage, the cost of inter-panel joint sealing pays off through heating savings.

Panel Building Joint Quality Control Methods: How to Check Contractor Work

Professional sealing quality verification ensures repair durability. Use these methods to verify the quality of completed inter-panel joint filling work.

Professional sealing quality verification ensures repair durability. Use these methods to verify the quality of completed inter-panel joint filling work.

Visual Quality Control

Initial assessment can reveal much about work quality. Pay attention to the following aspects:

- Sealant should be applied in an even layer without breaks

- Absence of bubbles and blisters in the material

- Good surface adhesion (checked by light pressure)

- Proper joint geometry (convex profile for water drainage)

- Absence of sealant drips and flows

These simple checks help identify obvious work defects during acceptance stage.

Instrumental Verification Methods

More precise joint sealing quality assessment methods require special tools and knowledge:

- Adhesion test: 7 days after application, sealant shouldn't peel off under tension

- Elasticity check: quality sealant stretches at least 200% without tearing

- Thermal imaging survey: reveals hidden defects and cold bridges

- Water test: joint water testing for leak tightness

Instrumental control provides objective assessment of completed work quality.

Documentary Control

Mandatory documents for work acceptance include:

- Hidden work act with photo documentation of stages

- Certificates for all materials used

- Contractor's warranty obligations for joint sealing

- Quality certificates for sealants with production date

- Permits for industrial alpinism work

A complete document package guarantees contractor responsibility and ability to make claims if problems arise.

"In my 15 years as a construction work acceptance expert, I've seen all types of defects. The most common problem—contractors save on primer or dilute sealant. Simple test: a week after work, try to pick off a piece of sealant with your fingernail. If it comes off easily—work is poor quality. Quality sealant should tear, not peel off," advises Igor Semenov, independent construction expert.

Environmental Aspects: Choosing Safe Materials

Modern environmental requirements for construction materials make sealant selection even more responsible. When ordering joint sealing services, pay attention to materials' environmental characteristics.

Joint Filling Material Environmental Comparison

Choosing eco-friendly materials shows care for residents' health and the environment. Let's compare main sealant types by safety level:

| Sealant Type | VOC Content | Application Odor | Health Safety | Application Recommendations |

|---|---|---|---|---|

| Water-based | < 30 g/L | None | High | Ideal for interior work and cheap joint repair |

| MS-polymers | < 40 g/L | Weak | High | Universal application, optimal for warm joint technology |

| Polyurethane | 50-100 g/L | Moderate | Medium | Only with good ventilation, ideal for facade joints |

| Acid-cure silicone | > 100 g/L | Strong | Low | Only exterior work for alpine joint sealing |

When choosing sealant for interior work, always prefer materials marked EC1 Plus (very low emission) or similar. This is especially important when repairing balcony joint leaks or in living spaces.

Alternative Sealing Methods: When and What to Choose

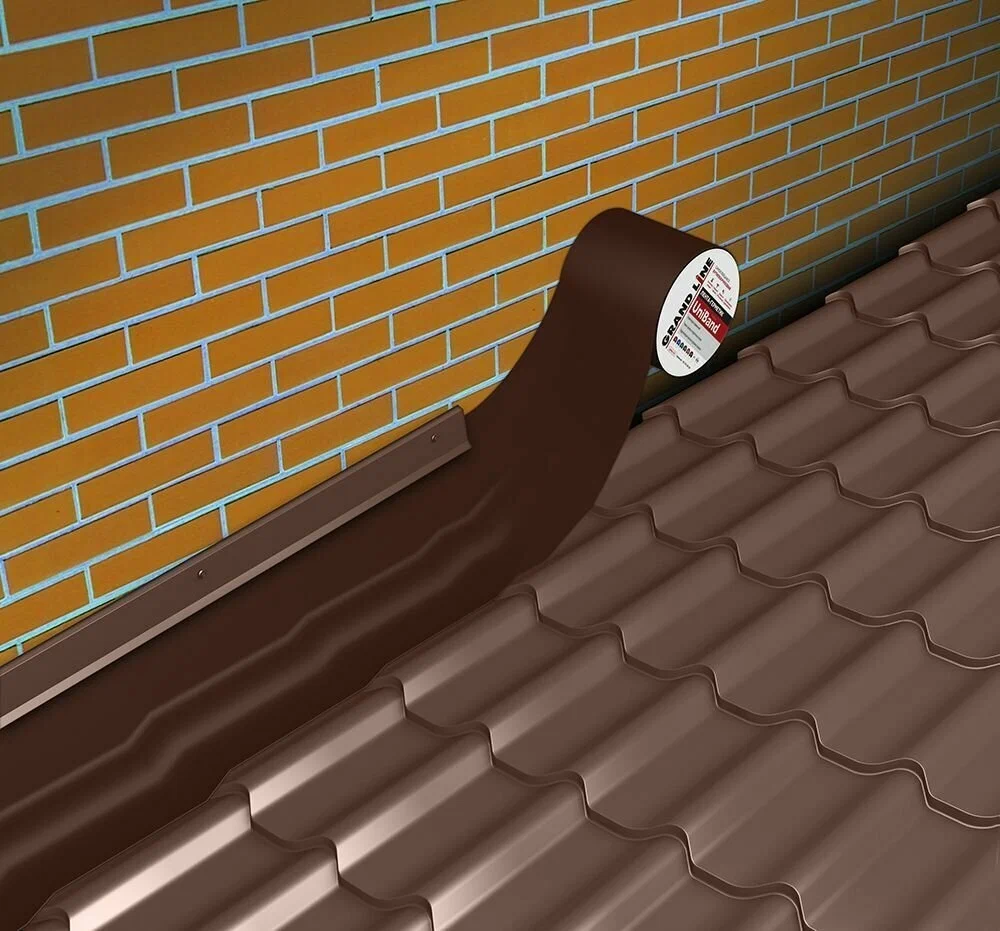

Tape Joint Sealing — Quick Solution

Using special sealing tapes is a modern approach to inter-panel joint treatment. Let's examine this method's features:

Using special sealing tapes is a modern approach to inter-panel joint treatment. Let's examine this method's features:

- Advantages: quick installation, no curing time, ability to work in any weather

- Disadvantages: limited durability (10-15 years), high price per meter

- Application: temporary repair, hard-to-reach places, emergency sealing

- Materials: butyl rubber based tapes, EPDM, thermoplastic elastomers

Tape sealing is an excellent solution for quick leak elimination but doesn't replace major repair.

Shape Memory Sealing Cords

Innovative technology for difficult operating conditions presents an interesting solution for problem joints:

- Advantages: self-adaptation to joint width changes, durability

- Disadvantages: high sealing cost ($15-20 per meter)

- Application: expansion joints in seismically active zones

- Features: expand on contact with moisture, creating additional barrier

This technology is especially effective in regions with large temperature variations and seismic activity.

Compensation Profiles for Large Deformations

Professional solution for complex cases requires special approach:

- Advantages: reliability with large deformations, 30+ year durability

- Disadvantages: installation complexity, requires qualified specialists

- Application: expansion joints, dissimilar material joints

- Materials: aluminum, stainless steel, special polymers

Alternative method selection should be based on specific operating conditions and project budget. Specialist consultation helps determine the optimal option for your case.

"In our region with high seismic activity, traditional sealants lasted maximum 2-3 years. Switching to compensation profiles with elastic inserts solved the problem once and for all. Yes, initial investment was 3 times higher, but in 8 years of operation—not a single repair. The savings are obvious," says Takeshi Yamamoto, Chief Engineer at Tokyo Building Management.

Practical Checklist for Ordering Joint Sealing Services

Before ordering joint sealing, use this detailed checklist to avoid typical problems and ensure quality results:

- ☐ Permission obtained from management company for work

- ☐ Work coordinated with neighbors (especially above and below)

- ☐ Weather forecast checked for 3 days ahead (no precipitation)

- ☐ Contractor provided all documents and warranties

- ☐ Detailed estimate agreed without hidden charges

- ☐ Work start and completion dates determined

- ☐ Work acceptance procedure and quality criteria discussed

- ☐ Certificates for sealing materials verified

- ☐ Work technology clarified for your building type

- ☐ Quality control methods agreed upon

- ☐ Possible defect elimination procedure determined

- ☐ Warranty obligations and terms clarified

This expanded checklist helps avoid 95% of conflict situations with contractors and ensures transparency throughout the turnkey joint repair process.

"In my practice managing residential complexes, the most successful sealing projects are those where residents actively participated in the process. When people understand the technology, control quality, and know their rights, contractors work much better. I recommend this checklist to all my clients," states James Mitchell, property management consultant with 25 years of experience.

Calculating Economic Efficiency of Joint Sealing

Understanding the financial side helps make an informed decision about repair necessity. Let's consider real numbers for a typical apartment:

Understanding the financial side helps make an informed decision about repair necessity. Let's consider real numbers for a typical apartment:

| Parameter | Value | Calculation/Note |

|---|---|---|

| Joint length in 3-room apartment | 45-60 m | Depends on layout and floor |

| Complete sealing cost | $2,700-3,600 | At $60 per meter |

| Monthly heating savings | $40-60 | With 25-30% heat loss reduction |

| Investment return | 3-5 years | $480-720 annual savings |

| Leak damage prevention | $500-1,500/year | Finish repair, wallpaper replacement |

These calculations show that quality inter-panel joint waterproofing isn't an expense but an investment with guaranteed return and additional benefits for living comfort.

Future Innovative Sealing Technologies

The construction materials industry doesn't stand still. New developments promise to revolutionize the approach to inter-panel joint sealing:

Self-Healing Materials

Unique technology that could change joint maintenance approach:

- Operating principle: polymer microcapsules activate when cracks appear

- Advantages: automatic micro-damage repair

- Status: undergoing field testing, commercial launch expected 2025-2026

- Expected cost: 40-50% more expensive than traditional sealants

This technology will significantly increase intervals between preventive repairs.

Nanotechnology in Sealants

Nanoparticle application opens new possibilities:

- Features: nanoparticles improve adhesion and elasticity

- Effect: service life increase to 40-50 years

- Application: already used in premium segment

- Prospects: price reduction with mass production

Nano-sealants will become industry standard in the next 5-7 years.

Smart Sealants with Condition Indication

Visual joint condition control without special equipment:

- Technology: color change when properties are lost

- Benefit: visual joint condition monitoring

- Development: being tested in laboratory conditions

- Potential: simplified preventive maintenance

This technology will allow residents to independently determine repair necessity.

"The future belongs to intelligent materials. Imagine a sealant that signals the need for replacement by changing color from white to red. Or material that automatically 'heals' microcracks. We're already testing such solutions in the laboratory. In 5 years, this will become reality," predicts Dr. Sarah Johnson, Head of Advanced Building Materials Research Center.

Regional Features and Recommendations

Climate conditions in different regions require an adapted sealing approach. Here are specific recommendations for different zones:

Northeastern US and Canada

Extreme winter conditions require special approach:

- Use of frost-resistant sealants operating down to -40°C

- Increased insulation thickness (50-60 mm foamed polyethylene)

- Mandatory protection from roof ice dams

- Application of sealants with enhanced elasticity (>500%)

Proper material selection for these regions is critical for sealing durability.

Southern Coastal Regions

High humidity and salt air create specific problems:

- Emphasis on UV radiation resistance

- Use of materials with antifungal additives

- Enhanced salt air resistance

- Frequent maintenance due to high humidity

Protection from biological corrosion is especially important in these conditions.

Mountain Areas

High altitude specifics require special solutions:

- Consideration of large daily temperature variations

- Use of materials with high vapor permeability

- Protection from intense UV radiation at altitude

- Special solutions for seismically active zones

Materials must withstand extreme high-altitude conditions.

"Working in Colorado at 3,000 meters altitude, we encountered a unique problem: during the day, sealant softened from sun, and at night hardened from cold. Regular materials lasted maximum one season. We found solution in special UV-resistant compounds with extended temperature range. Cost 60% more but last 5 times longer," shares Robert Stone, Project Manager at Mountain Construction Group.

Legal Aspects of Sealing in Multi-Unit Buildings

Legal issues often become stumbling blocks in repair organization. It's important to know your rights and obligations:

Party Responsibilities

Clear responsibility distribution helps avoid conflicts:

- Management company: obligated to conduct routine repair and maintenance

- Residents: pay for work through fees, can demand quality execution

- Developer: bears warranty obligations first 5 years after building delivery

Knowing your rights helps achieve quality repair within established timeframes.

Repair Request Procedure

Follow established procedure for results:

- Written application to management company

- Problem documentation (photo, video, inspection act)

- Response waiting (30 days by law)

- Appeal to housing inspection if no response

- Legal proceedings as last resort

Following procedure significantly increases chances of positive issue resolution.

Documentation and Warranties

Proper document preparation protects your interests:

- Work contract with clear deadlines

- Estimate with material and work breakdown

- Acceptance act with warranty obligations

- Compliance certificates for all materials

Complete document package guarantees quality and ability to protect your rights.

"In my legal practice, 80% of disputes about poor-quality sealing were resolved in favor of residents who had a complete document package. Photos 'before and after,' written correspondence with management company, inspection acts—this is your insurance. Without documents, proving anything in court is practically impossible," emphasizes Maria Novikova, housing law attorney with 15 years of experience.

Conclusion: Your Path to a Comfortable Home

Inter-panel joint sealing is a comprehensive solution requiring professional approach, quality materials, and understanding of technological processes. Properly performed panel joint waterproofing solves problems with leaks, freezing, and mold for many years.

Investment in quality inter-panel joint repair pays off not only financially through heating savings but also through improved quality of life. Dry walls, absence of drafts, healthy microclimate—all these are results of proper sealing.

Don't postpone problem resolution—each season with leaky joints worsens the situation and increases future expenses. Use the knowledge gained to make the right choice of technology, materials, and contractors. Your home deserves reliable protection, and you deserve comfortable living without inter-panel joint problems.

Act now—order professional joint inspection, get specialist consultation, and begin the path to energy-efficient and comfortable housing. Remember: quality sealing today means peace of mind and savings for many years ahead.